製品情報 直動機器

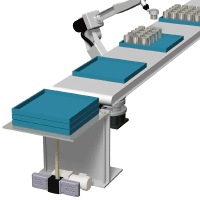

つばきの直動機器は、高品質な自社製ネジを使用している電動式のシリンダとジャッキ、当社独自のジップチェーン駆動のジップチェーンアクチュエータをラインアップしています。

ネジ機構とジップチェーン機構のいずれも、製品の持つ特長を最大限に活かし、高速・高頻度の運転や高い精度が求められる運転など、幅広い用途でご使用いただけます。

※ジップチェーン機構とは、2本のチェーンがジッパーのように噛み合うことで、1本の強固な柱状となり「押し・引き」で使用できる当社独自の技術です。

目次

直動機構の種類

ジップチェーン機構

- 高速

- 高頻度

- 高耐久性

- コンパクト

つばきの独自技術「ジップチェーン」を用いた機構です。

コンパクト性に優れ、高タクト運転に求められる高速・高頻度・耐久性を持っています。

2本のチェーンを噛合せ1本の棒状にすることで、押し引きを可能にしました。

ジッパーのように噛合う様子からジップチェーンと名づけました。

(ジップチェーン機構の特設サイトはこちら)

ボールネジ機構・台形ネジ機構

- 高頻度

- 大許容荷重

- 静粛性

ボールネジ機構

ネジ軸とナットの間に鋼球を入れ、転がり摩擦することで、高効率で動作できるようにした機構です。

台形ネジ機構に比べて高速・高頻度用途に適しているので、生産性が求められる組立ラインなどに適しています。

また、高効率なので駆動源を小形化することができます。

信頼性の高い内製のボールネジを使用しているため、走行寿命の予測も可能です。

ボールネジ1回転当たりの進む距離(リード)が通常のボールネジより長いものをハイリードボールネジと呼び、通常のボールネジと同じ入力回転速度でも高速化が実現できます。

台形ネジ機構

ネジ軸とナットが滑り摩擦することで動作する機構で、メンテナンス用途などの低速・低頻度での運転に向いています。

ボールネジ機構にはないセルフロック性を有しているので、荷重保持が可能です。

また、構造がシンプルなため経済的です。

つばきの直動機器製品群

| 電動シリンダ:パワーシリンダ | スクリュージャッキ: リニパワージャッキ |

ボールネジ昇降ユニット: リニスピードジャッキ |

噛合チェーン式アクチュエータ: ジップチェーンアクチュエータ |

||

|---|---|---|---|---|---|

|

|

|

|

||

| 機構の種類 | ボールネジ 台形ネジ |

ボールネジ ハイリード ボールネジ |

台形ネジ | ボールネジ | ジップチェーン |

| 目的 | 負荷の押し引き | 負荷の押し引き | 負荷の保持 | 負荷の押し引き | 負荷の押し引き |

| 特長 | モータ一体型で簡単配線 クリーンな環境を実現 |

各種ねじタイプを選択可 | 高速・高頻度、低床、長寿命 | 他機構を圧倒する高速・高頻度、 低床、長寿命 |

|

| 推力 | 最大490kN | 4.90kN~980kN | 1.96kN~980kN | 15kN~50kN | 400N~2000N |

| ストローク | 最大2000mm | 最大2000mm | 最大1500mm | 最大2000mm | |

| 速度・運転頻度 | 最大速度:333mm/s 負荷時間率:50%ED※1 |

ネジ軸最大速度: 50~120mm/s※2 許容負荷時間率: 30%ED |

ネジ軸最大速度: 40mm/s 許容負荷時間率: 20%ED |

ネジ軸最大速度:200mm/s 許容負荷時間率:100%ED※3 |

最大速度:1000mm 負荷時間率:100%ED |

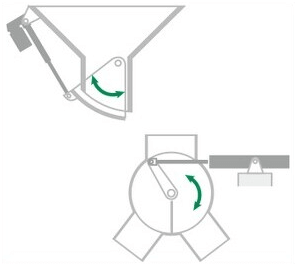

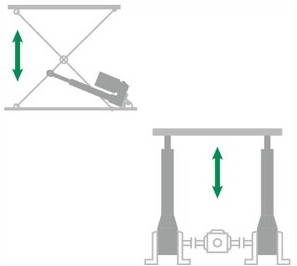

| 用途例 |

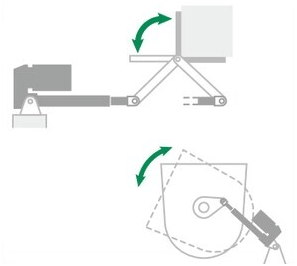

傾動装置

ストッパ |

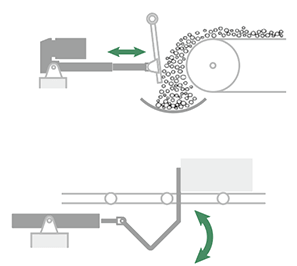

テーブル昇降

圧延ロール |

トラバーサの

取出し |

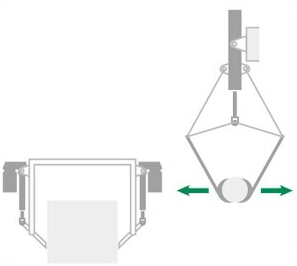

段積・段ばらし

パレットの |

|

- ※1 エコシリーズ サーボタイプの場合

- ※2 ネジタイプによって異なります

- ※3 条件により異なります

直動機器製品一覧

簡単な電気配線だけで使用できる電動シリンダです。

電動シリンダとは、原動機の回転を台形ネジあるいはボールネジとナットを組み合わせた機構によって推進力に変換することで、ロッドを前後に動かす直動機構です。主に負荷を押し引きする用途で使用されます。

幅広く用いられている油圧シリンダや空圧シリンダに比べて、電動シリンダは省エネ性・取り扱いの容易さ・メンテナンス性などの面でメリットが多い機構です。

(参考情報:油圧・空圧からの置換によるメリット)

つばきのパワーシリンダは、コンパクト設計と高速運転を実現し、優れた耐久性で装置の生産性向上に大きく貢献します。また、モータ 一体型なので電気配線が簡単で、設置工数の削減が可能です。つばきが半世紀以上にわたり磨き上げた製造技術により作り上げたパワーシリンダは、インフラ・IT/半導体設備・鉄鋼設備・港湾設備・環境設備・各種検査装置・自動車製造設備等の幅広い業界・用途でその実力を発揮しています。

用途例

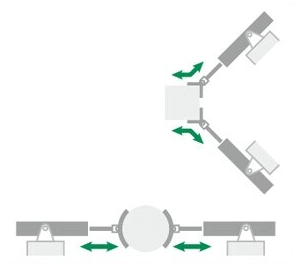

| 開閉 | 昇降 | 反転 | ストッパ | ハンドリング | 位置決め |

|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

Uシリーズ

形番 LPUB~/LPUC~

小形軽量化を実現した定格推力6トン以上の電動シリンダ「パワーシリンダ Uシリーズ」。

(大推力58.8kN以上)

- ・軽量・コンパクト:

新開発の高機能ボールネジとベアリング強化により、従来品 (Tシリーズ)最大で全長寸法10%、

質量35%の低減に成功。小形軽量化により、油圧シリンダからの置換えも容易になりました。 - ・充実のラインアップ:

定格推力50トンを機種拡大、内径Φ250mmクラスの油圧シリンダと置換えしやすくなりました。 - ・コストパフォーマンス向上:

部品の小形軽量化で従来品からのコストダウンを実現したことに加え電動式のため、油圧式と比べて

節電効果が大きく、電力使用量を大幅に削減します。 -

エコ&エコ ポイント

【部品のサイズダウンによる小形軽量化】

定格推力 kN

58.8~490

速度 mm/s

50Hz:6.5~43

60Hz:7.8~52

ストローク mm

500~2000

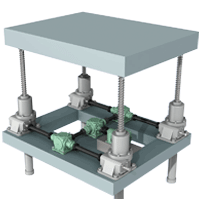

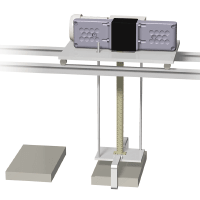

Uシリーズ マルチ仕様

形番 LPUA□□□□B~ LPUC□□□□B~

1台のモータで複数のシリンダを完全に同調できる電動シリンダです。(大推力58.8kN以上)

- ・高速対応:

最大150mm/sの高速運転が特形として対応可能です。 - ・安全:

過負荷を検知し、保護を行う推力検知機構が内蔵できます。(LPUC) - ・タフな構造:

荷重を支える作動部と減速部を分離しました。変動荷重によるギヤの歯当り変化はありません。 - ・複数台の連動可能:

十分な強度を持つ入力軸の使用により、複数台の連動が可能です。 - ・揺動運転可能:

入力軸とトラニオン部が同一軸心ですので、連動運転しながら揺動も可能です。 -

エコ&エコ ポイント

【コンパクト】【長寿命】

許容推力 kN

58.8~313

速度 mm/s

50Hz:6.5~43

60Hz:7.8~52

ストローク mm

500~2000

Tシリーズ

形番 LPTB~/LPTC~

AC(交流)電源でご使用いただける中推力ゾーンの電動シリンダです。(中推力39.2kN以下)

- ・2つの安全機構:

保護方式でタイプをお選びいただけます。TBタイプは湿式のスリップスリップクラッチが内蔵されています。TCタイプは推力検知リミットスイッチ付です。 - ・ワイドバリエーション:

用途、推力、速度にあわせて広範囲な機種を標準でご用意しています。

推力は2.45kN~39.2kN、速度は9mm/s~120mm/sからお選びいただけます。 - ・確実な作動:

信頼性の高い安全装置を内蔵していますので、過負荷に対して有効に働きます。 - ・豊富なオプション:

ストローク調整リミットスイッチは外部式と内部式の2種類、ストロークセンサはポテンショメータ方式とロータリーエンコーダ方式の2種類をご用意しています。 -

エコ&エコ ポイント

【CO2排出量低減】【電気代低減】

定格推力 kN

2.45~39.2

速度 mm/s

50Hz:9~100

60Hz:11~120

ストローク mm

200~1500

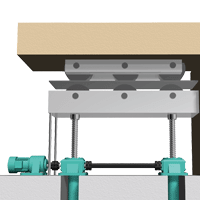

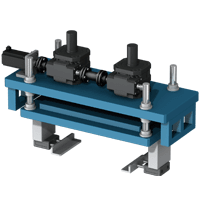

Tシリーズ マルチ仕様

形番 LPTB□□□□B~ LPTC□□□□B~

1台のモータで複数のシリンダを同期運転する場合に最適です。(中推力39.2kN以下)

- ・安全:

過負荷を検知し、保護を行う推力検知機構が内蔵できます。(LPTC) - ・タフな構造:

荷重を支える作動部と減速部を分離しました。変動荷重によるギヤの歯当り変化はありません。 - ・複数台の連動可能:

十分な強度を持つ入力軸の使用により、複数台の連動が可能です。 - ・揺動運転可能:

入力軸とトラニオン部が同一軸心ですので、連動運転しながら揺動も可能です。 -

エコ&エコ ポイント

【コンパクト】【長寿命】

許容推力 kN

4.94~39.2

速度 mm/s

72~120

ストローク mm

200~1500

ウォームシリーズ

形番 LPWB~

ウォームシリーズは油圧シリンダからの置換えに最適な電動シリンダです。

- ・つばきが長年培った技術を生かした高精度ウォームギヤと、高効率ボールネジを採用し、大推力を実現しました。

- ・クリーン:

油圧ポンプや配管がないので、接合部からの油漏れの心配がありません。 - ・設置が簡単:

油圧ポンプや配管は不要。三相電源をつなぐだけで動作が可能です。 - ・正確な制御が可能:

インバータなどにより、速度変更や正確な位置決めが可能です。 - ・低コスト:

部品点数を大幅に削減し、コストダウンを実現しました。 - ・高負荷容量:

特殊鋼合金の採用により、ジャッキと同じく大荷重にも対応可能です。 -

エコ&エコ ポイント

【CO2排出量低減】【電気代低減】

定格推力 kN

49~490

速度 mm/s

5~72(参考値)

ストローク mm

200~2000(参考値)

Gシリーズ

形番 LPG~

AC(交流)電源でご使用いただける小推力ゾーンの電動シリンダです。(推力3.00kN以下)

- ・ワイドバリエーション:

基本形630種、オプション搭載機種を加えると、約9000機種を標準化。 - ・安定した高効率・長寿命:

専用設計した調心性台形ネジ(セントラライジングネジ)と相性の優れたナット材質の採用により、安定した高効率、長寿命を実現しました。 - ・用途に合わせてネジの種類を選択可能:

基本的には台形ネジを使用しています。高速・高頻度運転で使用したい場合には、ボールネジタイプにてご検討ください。 - ・静粛運転:

静音DCブレーキモータ駆動により起動時・停止時の騒音を大幅に低減しました。 - ・優れた速度安定性:

負荷変動の影響を受けにくい、安定した速度運転が可能です。 -

エコ&エコ ポイント

【CO2排出量低減】【電気代低減】

定格推力 N

700~3.00k

速度 mm/s

50Hz:25~200

60Hz:30~240

ストローク mm

100~1200

Fシリーズ

形番 LPF~

DC(バッテリー)電源で駆動用の小推力タイプの電動シリンダです。

- ・小形・軽量、据付スペースを有効活用:

作動部とモータ部を直交に配置したコンパクト設計です。クレビス金具は直交する2方向に空いていますので、相手機械に干渉しないように、4方向に据付が選べます。 - ・屋外での使用が可能:

農業機械や立体駐車場など屋外でのご使用に最適です。 - ・豊富なオプション:

位置検出ユニット、過負荷検知ユニット等各種オプションを豊富にご用意。 -

エコ&エコ ポイント

【CO2排出量低減】【電気代低減】

定格推力 N

100~6.00k

速度 mm/s

8~54

ストローク mm

50~600

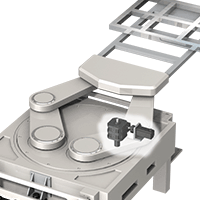

エコシリーズサーボタイプ

形番 LPES~

サーボモータの性能を最大限に活かせるよう、高速・高精度運転に対応可能です。

- ・サーボモータの性能を最大限に発揮:

高効率ボールネジと高剛性・軽量のディスクカップリングの組合せにより、サーボモータの性能を最大限に発揮します。 - ・高い停止精度を実現:

高精度ボールネジの採用により高い停止精度を実現します。繰返位置決め精度は±0.02mm、停止精度は±0.1mm以内です。 - ・精密遊星減速機付きの効果:

サーボモータのサイズダウンにより周辺機器も小さく出来、イニシャルコストの低減が図れると共に、電力量も小さくなりランニングコストも削減できます。 - ・サーボモータの選択が可能:

お客様ご希望のサーボモータをお取付けいただけます。お見積時にはサーボモータメーカまたはマウントコードをご連絡ください。 - ・高速・幅広い推力を実現:

高速かつ大推力域での使用が可能です。 -

エコ&エコ ポイント

【廃棄物排出量低減】【電気代低減】

定格推力 N

150~15.0k

速度 mm/s

1~333

ストローク mm

300~1000

エコシリーズ CDS タイプ

形番 LPE~

エアシリンダのような2点間運転での使用用途に最適。電流検知式の自己完結機能付きです。

- ・自己完結:

作動部に内蔵したバネと、端子箱内部に搭載したCDS(Current Detective System)により、押し付け

停止時や万が一の過負荷が生じた場合でも過電流を検知し、モータを自動停止させます。

停止中は内蔵バネにより押付力を保持します。 - ・ランニングコスト低減と環境への配慮:

電動式ですので、使用時のみの電力消費となり経済的です。エア方式のようにコンプレッサを常時運転させる必要がなく、大幅なランニングコストの低減が図れます。 - ・高頻度運転・長寿命:

最大15回/分の高頻度運転が可能。またボールネジの採用により、100万往復の長寿命が期待できます。 - ・簡単操作:

三相電源をつなぐだけで操作可能です。ストローク調整用のリミットスイッチも不要ですので、面倒な配線等もありません。長い配線距離もOKです。 -

エコ&エコ ポイント

【廃棄物排出量低減】【電気代低減】

定格推力 N

250~1.00k

速度 mm/s

200V 50Hz:90~160

200V 60Hz:90~190

220V 60Hz:110~200

ストローク mm

100~600

定格推力 N

98.0~392

速度 mm/s

50Hz:9~34

60Hz:11~42

ストローク mm

100~300

各シリーズの使い分けにあたっては、下記資料もご参照ください。

油圧・空圧シリンダから電動シリンダ(パワーシリンダ)への置換によるメリット

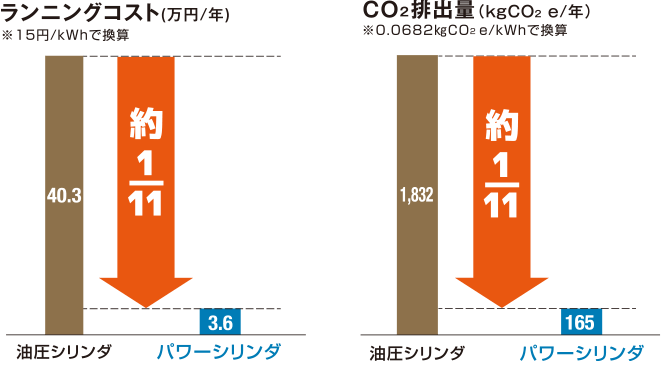

節電効果とコストパフォーマンス

幅広く用いられている油圧・空圧シリンダは、

・ポンプやコンプレッサを実際の運転時間よりも長く稼働させなければならない

・システムが複雑なので効率が悪い

などのような理由から、電力の使用量が大きくなりがちです。

一方、パワーシリンダは、

・運転時しか電力を消費しない

・システムがシンプルなので効率が良い

ため、同じ仕事量でも消費電力に大きな差が出ます。

より詳しい資料はこちらからご確認ください。

設置性とメンテナンス性の向上

電動化でシステム構成が簡単になるため、設置が容易です。

駆動源はケーブル接続のみ。油圧・空圧シリンダで必要な配管やポンプなどは不要で、本体や配管からの油漏れも心配ありません。

また、油圧シリンダでは定期的に行わなければならない油の交換や、配管内に蓄積するスラッジ(堆積物)の除去なども不要なので、メンテナンス費用・工数を大幅に削減することができます。

油圧・空圧シリンダはシステム構成が複雑

パワーシリンダはシステム構成がシンプル

制御性・安全性の向上

油圧・空圧では周囲の温度が推力に影響を与えます。特に油圧では油の粘性が周囲温度に影響され推力に影響するため、適切な油温管理が必要です。

また、負荷の大きさによって作動速度が変化します。よって、どんな温度・負荷でも一定の速度・推力で安定させるのは難しい機構です。

一方、パワーシリンダは常に安定した推力・速度を得ることができます。

据付方向や作動方向に関係なく一定の速度で運転できます。また、ブレーキ付モータにより、負荷を保持している間は電気を供給する必要がないため、停電時などの落下事故も心配ありません。

パワーシリンダなら負荷条件に関わらず速度が安定

ブレーキによる停止位置荷重保持が可能

その他関連資料:

油圧シリンダから電動シリンダ(パワーシリンダ)への置換ガイド

現在ご利用の油圧シリンダから推力を算出し、適合するパワーシリンダを絞り込めるツールはこちら

油圧シリンダ仕様とパワーシリンダ対応モデルの早見表

| シリンダ内径 mm |

ピストンロッド径 mm |

使用圧力 | |||

|---|---|---|---|---|---|

| 7MPa | 10MPa | 14MPa | 21MPa | ||

| 100 | 56 | LPT4000 | LPT4000 | LPU6000 | LPU8000 |

| 125 | 70 | LPT4000 | LPU6000 | LPU8000 | LPU12000 |

| 140 | 80 | LPU6000 | LPU8000 | LPU12000 | LPU16000 |

| 160 | 90 | LPU6000 | LPU12000 | LPU12000 | LPU22000 |

| 180 | 100 | LPU8000 | LPU12000 | LPU16000 | LPU32000 |

| 200 | 110 | LPU12000 | LPU16000 | LPU22000 | LPU32000 |

| 224 | 125 | LPU12000 | LPU16000 | LPU32000 | LPU50000 |

| 250 | 140 | LPU16000 | LPU22000 | LPU32000 | LPU50000 |