大形コンベヤチェーン継手リンク スクリューロックリンク

- トルクレンチ一つで、誰でも簡単・安全・確実に切継ぎが可能に

- 危険で技術が必要な大形コンベヤチェーンの切継ぎ作業が、トルクレンチひとつで誰でも簡単に実施できるようになる継手リンクです。

- 従来はハンマーを使って行われていた切継ぎですが、

- ・危険

ハンマーで強くたたかなければならないので、破片が飛散したり、手を打ち付けるなど労災のリスクがある - ・技術が必要

適切に行わないと、外プレートの押し込みすぎによる屈曲不良が発生することも - ・工数がかかり生産性に影響

前述のように技術が必要なため、技術者の手配が必要なことも - ・大掛かりな工具が必要

チェーンが大きくなるにつれて、大掛かりな工具・治具が必要な場合も - など、様々な課題がありました。

- スクリューロックリンクなら、トルクレンチでナットを指定のトルクで締めるだけなので、誰でも簡単・安全・迅速・確実に切継ぎ作業が行えます。

カタログ・取扱説明書

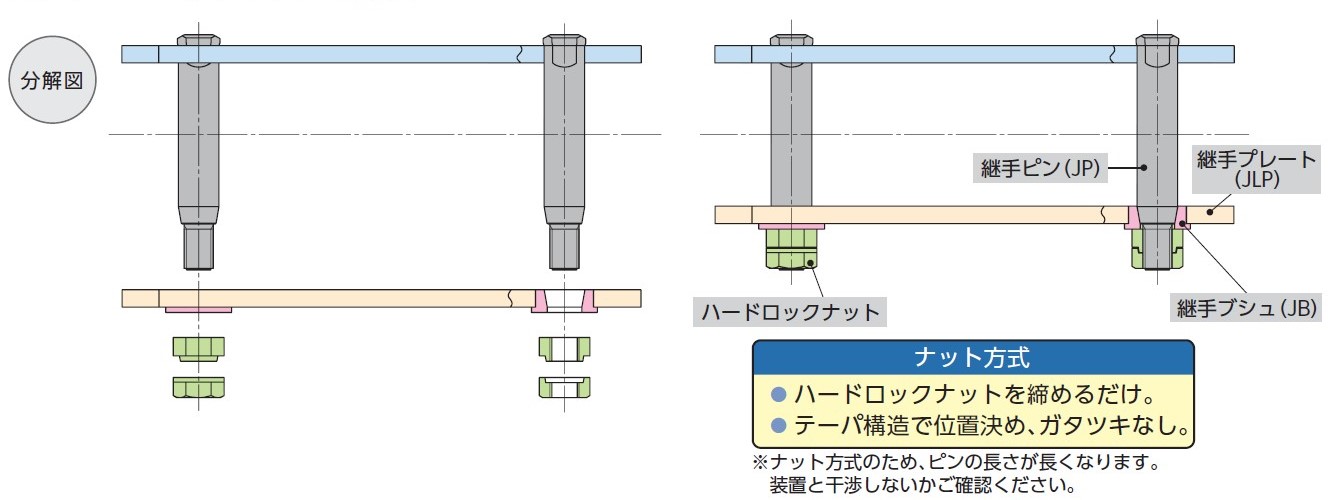

構造

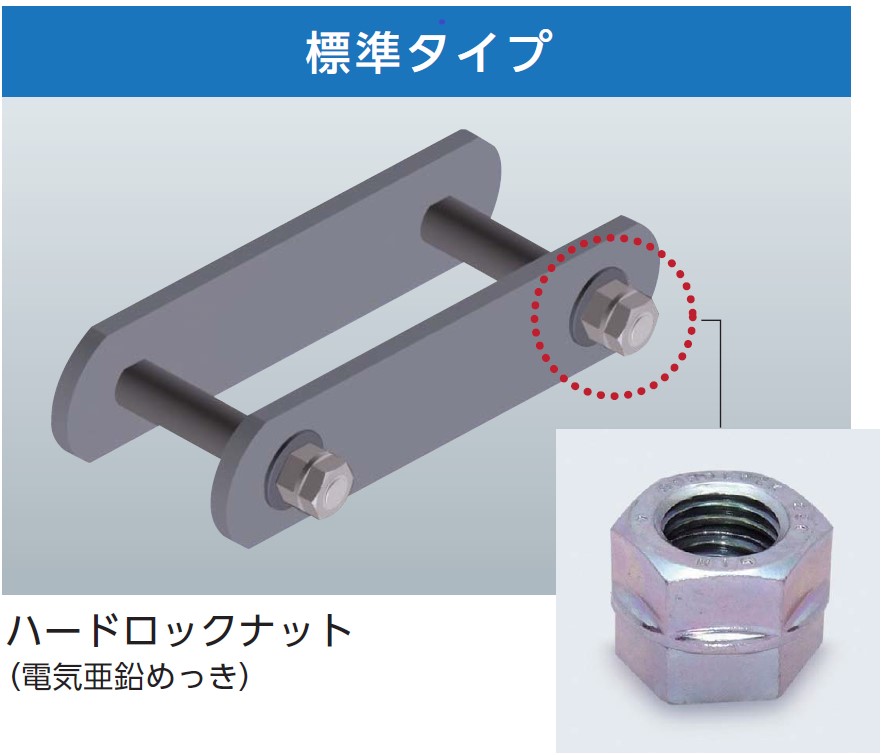

ナット部は選べる2タイプ

ピンの長さを極力抑えたショートタイプもご用意できます。

※ハードロックナット、ハードロックベアリングナットは、ハードロック工業株式会社の商標、または登録商標です。

主な適用可能製品

その他、製作可能な仕様については下記をご確認ください。

取扱要領

| ⚠注意 |

水平・傾斜・および垂直いずれのコンベヤの場合もチェーンブロック、ワイヤなどで切継ぎ部にチェーン張力がかからないようにしてから切継ぎ作業をしてください。 |

|---|

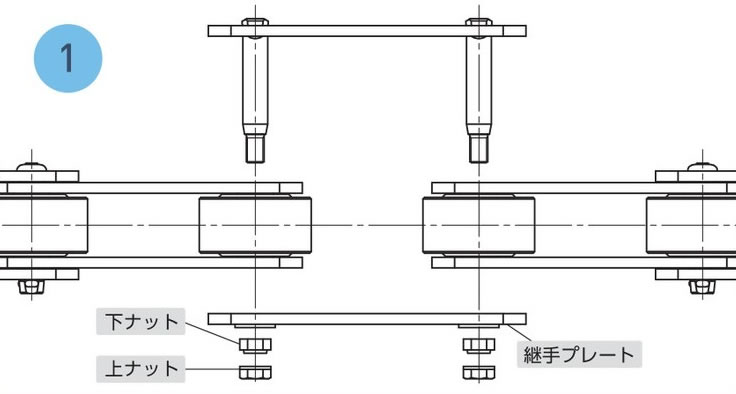

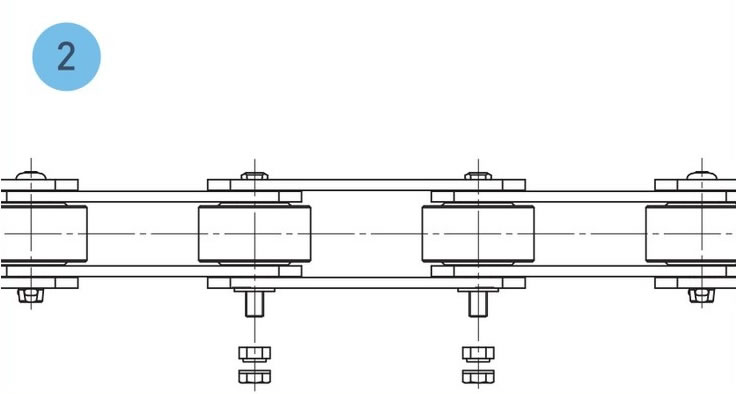

継ぎ方

1. ナットを外し、継手プレートを外した状態にします。

2. チェーンの両端を引き寄せ、継手リンクを内リンクの継ぎ目に挿入し、継手プレートをかぶせます。

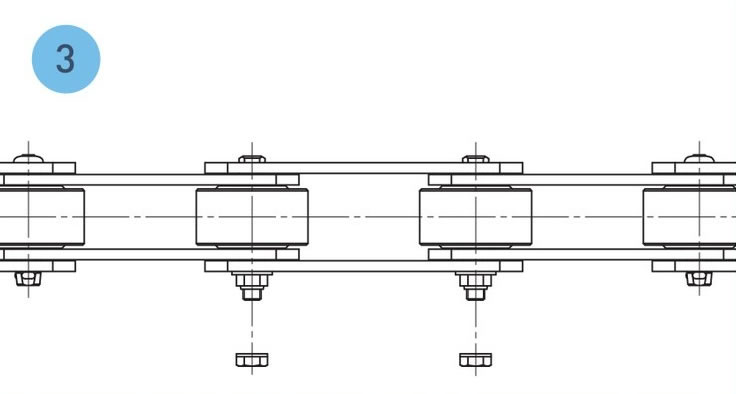

3. 下ナットを下記の指定のトルクで締め付けます。ナット締付け時、ネジ部の油分や付着物は、ウエスなどで拭き取ってください。

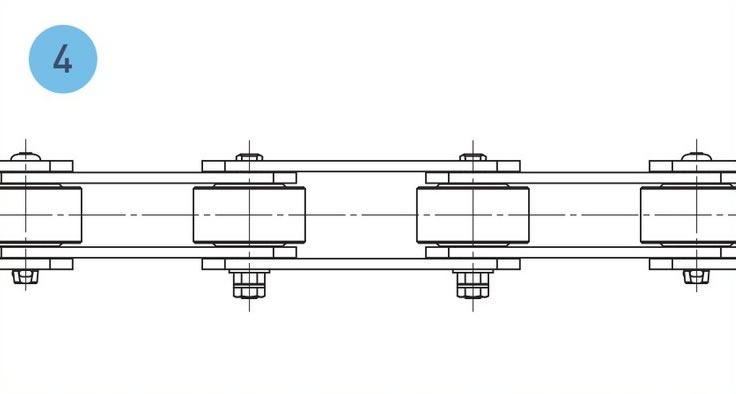

4. 上ナットを下記の指定のトルクで締め付け、連結完了です。

ナットの締め付けトルク(N・m) ※1

| RF10 | RF12 | RF17 | RF26 | RF36 | RF52 | RF60 | RF90 | ||

|---|---|---|---|---|---|---|---|---|---|

| 標準タイプ※2 | ナットサイズ | M12×P1.75 | M12×P1.75 | M14×P2.0 | M16×P2.0 | M20×P2.5 | M24×P3.0 | M27×P3.0 | M30×P3.5 |

| 下ナット | 27~32 | 28~33 | 46~55 | 72~82 | 120~130 | 218~228 | 250~260 | 367~377 | |

| 上ナット | 27~32 | 28~33 | 46~55 | 72~82 | 120~130 | 218~228 | 250~260 | 367~377 | |

| ショートタイプ※3 | ナットサイズ | M12×P1.0 | M12×P1.0 | M15×P1.0 | M17×P1.0 | M20×P1.0 | M25×P1.5 | M30×P1.5 | M35×P1.5 |

| 下ナット | 23~27 | 28~33 | 49~58 | 76~86 | 117~127 | 227~237 | 254~264 | 428~438 | |

| 上ナット | 16~19 | 16~19 | 28~33 | 37~44 | 55~65 | 80~90 | 115~125 | 130~140 | |

- ※1.上記の表はスチールナットの締付トルクです。ステンレス製ナットの締付トルクはお問い合わせください。

- ※2.下ナット締付け時ボルトが突き出しますので、標準タイプはディープソケットのご使用を推奨します。

- ※3.ショートタイプは4切欠き形ナットです。引掛けスパナやソケットをご使用ください。

切り方

- 1. 上ナット、下ナットの順にナットを外します。

※搬送物などの固着や腐食の影響によりナットが容易に取り外せない場合もあります。 - 2. 継手プレートを外し、継手リンクを内リンクから外します。

保守・点検の注意

使用環境や条件によってはナットの緩みや脱落の可能性があるため、チェーン稼働中にナットの緩みが起きていないか定期的に確認してください。 (ナットにはマーカで合マークを入れると確認しやすくなります。)

形番表示例

編成品

| RF12200 | R | - | DT | - | 1L | A2 | + | 400L | - | LNJR | - | H | ||||||||||||||||

| | サイズ |

| | | |

| 仕様記号 |

| | | | | |

| | | |

| リンク数 |

| | | |

| オプション記号 |

|||||||||||||||||||||

| ローラ形式 |

アタッチメント形式

|

端末記号 ×

(ドラッグで移動できます)

※スクリューロックリンク(継手リンク)の下ナットは規定のトルクをかけた状態で、上ナットは、軽く締め付けた状態で出荷します。 |

||||||||||||||||||||||||||

| | アタッチメント取付間隔 1L:各リンク取付 2L:2リンク毎取付 |

||||||||||||||||||||||||||||

継ぎ手リンク単体

| RF12200 | - | DT | - | A2 | - | LNJL | - | 8K | |

| | サイズ |

| 仕様記号 |

| | アタッチメント形式 |

| 部品名 LNJL:標準タイプ LSJL:ショートタイプ |

| 数量・単位(個) |

|||||

商品スペック一覧

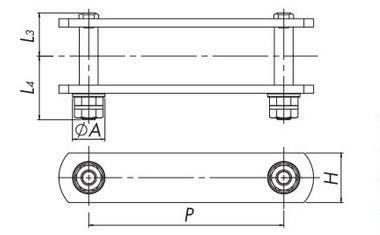

標準タイプ

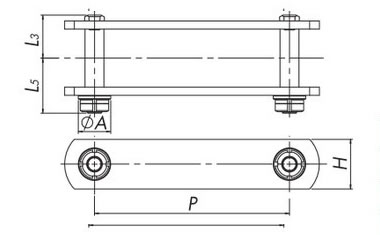

ショートタイプ

| サイズ | 最大許容張力 | 最小引張強さ | ピッチ P |

ピン | ナットサイズ | 継手ブシュ フランジ径 |

概略付加質量 (kg/ヶ所) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 継手ピン | |||||||||||||

| DT kN{kgf} |

AT kN{kgf} |

DT kN{kgf} |

AT kN{kgf} |

L3 | 標準 タイプ |

ショート タイプ |

標準 タイプ |

ショート タイプ |

A | 標準 タイプ |

ショート タイプ |

||

| L4 | L5 | ||||||||||||

| RF10100 | 17.6 {1790} |

32.3 {3290} |

107 {11000} |

169 {17000} |

100 | 33 | 48.5 | 42 | M12 | M12 | 25 | 0.13 | 0.08 |

| RF10125 | 125 | ||||||||||||

| RF10150 | 150 | ||||||||||||

| RF12200 | 26.6 {2710} |

39.9 {4060} |

160 {16500} |

249 {25500} |

200 | 40.5 | 55.5 | 49 | M12 | M12 | 28 | 0.17 | 0.11 |

| RF12250 | 250 | ||||||||||||

| RF17200 | 35.0 {3570} |

55.3 {5640} |

213 {22000} |

336 {34000} |

200 | 51.5 | 69.5 | 61.5 | M14 | M15 | 32 | 0.25 | 0.14 |

| RF17250 | 250 | ||||||||||||

| RF17300 | 300 | ||||||||||||

| RF26200 | 44.9 {4570} |

74.3 {7580} |

285 {29000} |

448 {45500} |

200 | 55.5 | 74 | 64 | M16 | M17 | 36 | 0.33 | 0.17 |

| RF26250 | 250 | ||||||||||||

| RF26300 | 300 | ||||||||||||

| RF26450 | 450 | ||||||||||||

| RF36250 | 68.0 {6930} |

97.4 {9930} |

457 {46500} |

614 {62500} |

250 | 66 | 91.5 | 78.5 | M20 | M20 | 42 | 0.55 | 0.26 |

| RF36300 | 300 | ||||||||||||

| RF36450 | 450 | ||||||||||||

| RF36600 | 600 | ||||||||||||

| RF52300 | 71.4 {7280} |

147 {15000} |

481 {49000} |

953 {97000} |

300 | 79 | 110 | 93.5 | M24 | M25 | 48 | 0.85 | 0.39 |

| RF52450 | 450 | ||||||||||||

| RF52600 | 600 | ||||||||||||

| RF60300 | 71.4 {7280} |

149 {15200} |

479 {49000} |

1010 {103000} |

300 | 72.5 | 104 | 86.5 | M27 | M30 | 55 | 1.18 | 0.53 |

| RF60350 | 350 | ||||||||||||

| RF60400 | 400 | ||||||||||||

| RF90350 | 113 {11500} |

233 {23700} |

754 {77000} |

1600 {163000} |

350 | 85.5 | 120.5 | 102 | M30 | M35 | 65 | 1.85 | 0.88 |

| RF90400 | 400 | ||||||||||||

| RF90500 | 500 | ||||||||||||

注)

- 1. 使用温度範囲は、-20℃~150℃です。使用温度範囲外でのご使用については当社にご相談ください。

- 2. ピン長さL4、L5がL2通常のピンより大きくなります。装置側との干渉をご確認ください。

- 3. ショートタイプのナット締付けは引掛けスパナやソケットをご使用ください。

- 4. アタッチメント形式は「つばき大形コンベヤチェーン&スプロケット」カタログをご使用ください

- 5. 上表以外のサイズ(インチ系など)や仕様(ステンレス仕様など)も製作可能な場合があります。ご相談ください。

価格・納期一覧

DT仕様(標準タイプ)

| サイズ | アタッチメント | |||||||

|---|---|---|---|---|---|---|---|---|

| なし | A2 | K2 | GA2 | |||||

| 標準価格 | 納期 | 標準価格 | 納期 | 標準価格 | 納期 | 標準価格 | 納期 | |

| RF10100 | ¥26,400 | お問合せください | ¥26,900 | お問合せください | ¥27,600 | お問合せください | ¥26,900 | お問合せください |

| RF10125 | ¥26,700 | お問合せください | ¥27,100 | お問合せください | ¥27,800 | お問合せください | ¥27,100 | お問合せください |

| RF10150 | ¥27,100 | お問合せください | ¥27,600 | お問合せください | ¥28,000 | お問合せください | ¥27,600 | お問合せください |

| RF12200 | ¥30,400 | お問合せください | ¥31,600 | お問合せください | ¥32,900 | お問合せください | ¥31,100 | お問合せください |

| RF12250 | ¥30,700 | お問合せください | ¥32,200 | お問合せください | ¥34,000 | お問合せください | ¥31,600 | お問合せください |

| RF17200 | ¥34,200 | お問合せください | ¥36,400 | お問合せください | ¥33,800 | お問合せください | ¥35,300 | お問合せください |

| RF17250 | ¥34,700 | お問合せください | ¥37,100 | お問合せください | ¥40,000 | お問合せください | ¥35,800 | お問合せください |

| RF17300 | ¥35,300 | お問合せください | ¥38,700 | お問合せください | ¥42,400 | お問合せください | ¥36,200 | お問合せください |

AT仕様(標準タイプ)

| サイズ | アタッチメント | |||||||

|---|---|---|---|---|---|---|---|---|

| なし | A2 | K2 | GA2 | |||||

| 標準価格 | 納期 | 標準価格 | 納期 | 標準価格 | 納期 | 標準価格 | 納期 | |

| RF10100 | ¥26,900 | お問合せください | ¥28,200 | お問合せください | ¥29,100 | お問合せください | ¥28,000 | お問合せください |

| RF10125 | ¥27,100 | お問合せください | ¥28,400 | お問合せください | ¥29,300 | お問合せください | ¥28,400 | お問合せください |

| RF10150 | ¥27,800 | お問合せください | ¥28,900 | お問合せください | ¥29,800 | お問合せください | ¥28,900 | お問合せください |

| RF12200 | ¥31,600 | お問合せください | ¥33,300 | お問合せください | ¥35,100 | お問合せください | ¥32,700 | お問合せください |

| RF12250 | ¥32,200 | お問合せください | ¥34,200 | お問合せください | ¥36,700 | お問合せください | ¥33,600 | お問合せください |

| RF17200 | ¥36,200 | お問合せください | ¥38,900 | お問合せください | ¥41,300 | お問合せください | ¥37,800 | お問合せください |

| RF17250 | ¥37,100 | お問合せください | ¥40,000 | お問合せください | ¥42,700 | お問合せください | ¥38,900 | お問合せください |

| RF17300 | ¥37,800 | お問合せください | ¥41,600 | お問合せください | ¥45,300 | お問合せください | ¥39,800 | お問合せください |

※上記表に掲載のない仕様・サイズ、ショートタイプ、編成品は都度見積となりますので、お問い合わせください。