製品情報 高速リフタ

つばきの高速リフタは環境に優しい電動式で、ジップチェーン機構とネジ機構からお選びいただけます。

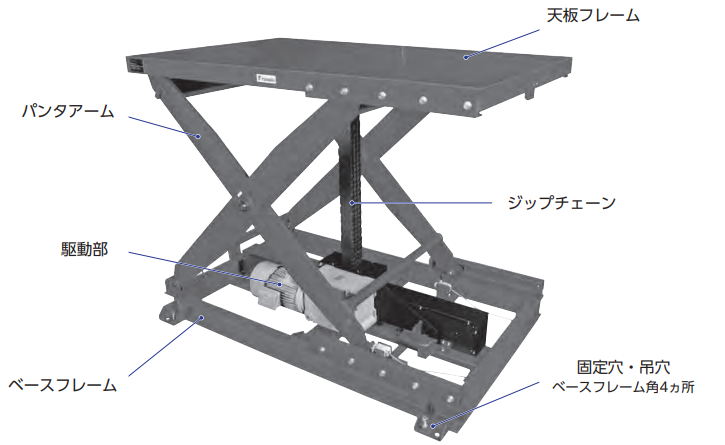

形状は、シザータイプのテーブルリフタとポストタイプの片持式リフタをラインアップしています。

テーブルリフタはジップチェーン機構を採用し、高速・高頻度の運転や昇降が可能です。

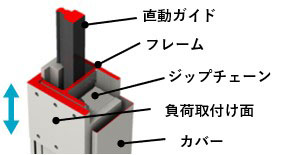

片持式リフタは剛性の高いフレームにガイドを内蔵したスリムな構造で、省スペース化を図れるだけでなく、設計・据付工数を削減いただけます。

※ジップチェーン機構とは、2本のチェーンがジッパーのように噛み合うことで、1本の強固な柱状となり「押し・引き」で使用できる当社独自の技術です。

リフタの対応領域

テーブルリフタ対応領域

ジップチェーンリフタ®

高速昇降・高頻度運転に対応したシザーリフタ

片持式リフタ対応領域

リフトマスタ®

組立不要・簡単設置 省スペースな片持式!

ジップマスタ®

高速・高揚程を実現 省スペースな片持式!

2種類のリフタをラインアップ

1.シザーリフタ

【ジップチェーンリフタ】ジップチェーンを使用した画期的なシザーリフタ

ジップチェーンとは?

- 高速・高頻度運転

- 多点停止機能

- ダントツの省スペース

ジップチェーンとは、2本のチェーンがジッパーのように噛み合い、1本の強固な柱状になり「押し・引き」ができる当社独自開発のチェーンです。

つばきジップチェーンアクチュエータは、このチェーンを使った直線作動機として製品化したものです。

従来の空圧・油圧シリンダに比べ、省スペース、高速・高頻度運転、多点停止機能、高停止精度、取付方向自由など、環境配慮点を含め多くの特徴を有し、小形アクチュエータから大形リフタまで幅広く使用されています。

装置の概要

他方式との比較

| ジップチェーンリフタ® | 電動・油圧リフタ |

|---|---|

|

|

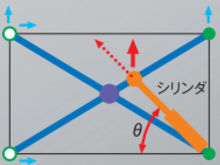

無駄のない伝達駆動ジップチェーンが直接天板を押すためモータトルクは無駄なく伝達されます。 抜群の耐久性ジップチェーンリフタは昇降部の質量及び推力をジップチェーンが支持し、シザーのヒンジやローラ部・軸受けに大きな力が働きません。 |

電動・油圧リフタは最下点からの起動時にシリンダにて斜めに押し上げるため、大きなパワー(昇降推力の1/sinθ倍の力)が必要です。 (例)  |

2. 片持式リフタ

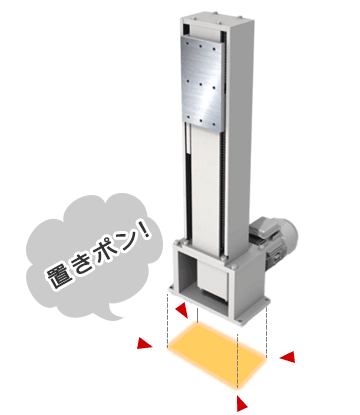

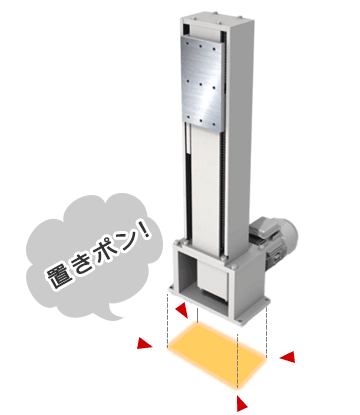

【ジップマスタ】置きポンで高速昇降できるジップチェーン式の片持式リフタ

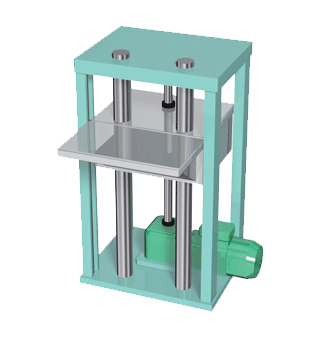

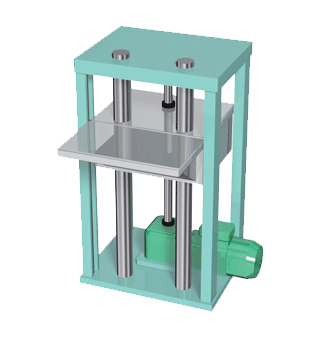

【リフトマスタ】置きポンで高精度な昇降ができるボールネジ/台形ネジ式の片持式リフタ

ジップチェーンとは?

- 高速・高頻度運転

- 多点停止機能

- ダントツの省スペース

ジップチェーンとは、2本のチェーンがジッパーのように噛み合い、1本の強固な柱状になり「押し・引き」ができる当社独自開発のチェーンです。

つばきジップチェーンアクチュエータは、このチェーンを使った直線作動機として製品化したものです。

従来の空圧・油圧シリンダに比べ、省スペース、高速・高頻度運転、多点停止機能、高停止精度、取付方向自由など、環境配慮点を含め多くの特徴を有し、小形アクチュエータから大形リフタまで幅広く使用されています。

置きポン形とは・・・組立不要・簡単設置ですぐに使える装置です

置きポン形リフタなら

- 組立不要

- 簡単設置

すぐにご使用できます

従来のリフタは・・・

設計・組立・据付工数

お客様のご負担

置きポン形とは・・・組立不要・簡単設置ですぐに使える装置です

置きポン形リフタなら

- 組立不要

- 簡単設置

すぐにご使用できます

従来のリフタは・・・

設計・組立・据付工数

お客様のご負担

| 片持式リフタ |

ジップマスタ®

|

リフトマスタ®

|

|---|---|---|

| 駆動方式 |

噛合チェーン式

ジップチェーン |

ネジ・ナット式

ボールネジ 台形ネジ |

| 内部構造 |

|

|

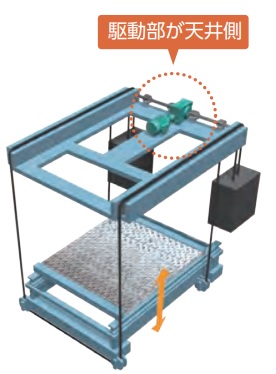

ドロップリフタとの比較

従来の垂直搬送リフタは現場での装置組み立てが必要な上、駆動部の設置や点検のために、天井側に足場を設けなければなりません。

ジップマスタは一体形構造なので、装置組み立て・設置がラク。

また駆動部が床面側に配置されているため点検やメンテナンス作業は安全・容易です。

高速リフタ製品一覧

リフトマスタ®はオーバーハング・横荷重を許容できる置きポン形の片持式リフタです。

組立不要で床にそのまま据付、アームを取付けるだけでモータに電源を接続すればすぐにご使用いただけます。

片持ち負荷(オーバハング荷重)を支えるために高剛性のフレーム内にネジ軸とガイドをコンパクトに内蔵しています。

高速・高頻度、長寿命が期待される用途にはボールネジタイプを、低速・低頻度で荷重保持が主な用途にはセルフロック性を有し、経済的な台形ネジタイプをご使用ください。

リフトマスタ® ボールネジタイプ

形番 LMEB~

サーボモータ駆動に対応できるボールネジタイプ

- ・高効率なため、小さな駆動源で大きな推力を得ることができます

- ・台形ネジタイプと比較して高速運転が可能です

- ・長寿命なので組立ラインなどの高頻度運転に適しています

- 置きポン形

- 片持式

昇降荷重 kN

1.96~9.80

速度 mm/s

25~166

リフトマスタ® 台形ネジタイプ

形番 LMEM~

セルフロック性のある台形ネジタイプ

- ・計算上セルフロックを有しており荷重保持が期待できます

- ・ボールネジタイプと比較して経済的です

- ・メンテナンス用途等の頻度が少ない運転に最適です

- 置きポン形

- 片持式

昇降荷重 kN

4.90~9.80

速度 mm/s

10~15