Q&A 高速リフタ

お客様から寄せられました「よくある質問」をQ&A形式で掲載しています。質問をクリックして回答へお進みください。

リフトマスタ

Q&A内で語句を

技術

対応・仕様

使用環境

| Q27 | 耐熱仕様は対応できますか?その場合の耐熱温度は何度まで可能ですか? |

|---|---|

| Q28 | クリーン度の高い雰囲気で使いたいのですが対応できますか? |

| Q29 | 屋外対応可能ですか? 水が掛かっても良いですか? |

| Q30 | 耐寒仕様は対応できますか? |

| Q31 | 耐熱仕様のジャバラはありますか? |

その他

| Q32 | 非該当証明書の依頼方法を教えてください。 |

|---|

| Q1 | 中間停止はどのように制御しますか? |

|---|---|

| A1 | サーボモータ付での制御を推奨します。三相モータ付の仕様では、オプション対応のロータリエンコーダ付[オプション記号:E]をご使用ください。 質問へ戻る |

| Q2 | リフタの繰り返し位置決め精度は? |

| A2 | 一定荷重の場合、繰り返し位置決め精度は、±1mmとなります。 質問へ戻る |

| Q3 | リフタの停止位置を複数設定することは可能ですか? |

| A3 | サーボモータ付、もしくは三相モータ付のロータリエンコーダ付[オプション記号:E]にすることで、複数箇所での停止制御が可能となります。 質問へ戻る |

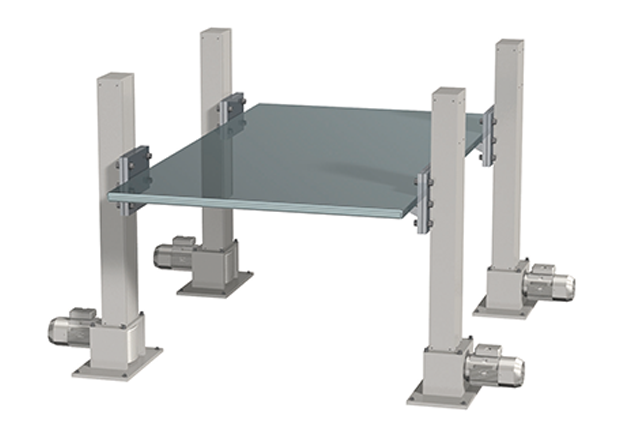

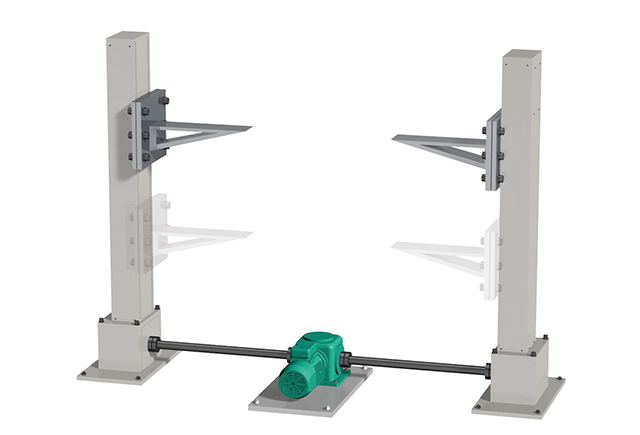

| Q4 | リフトマスタを複数台運転したいのですが、どのような方法が必要ですか? |

| A4 | 複数台運転には下記の方法があります。 |

| Q5 | 片持式リフタは、下方への押付け動作は可能ですか? |

| A5 | 原則として押付け動作はできません。 |

| Q6 | 片持式リフタは、自立形ですが上部先端に支えは必要ですか? |

| A6 | 標準機種は原則不要です。ただし、運転条件 (加減速・OHL等) により、支えが必要な場合があります。 質問へ戻る |

| Q7 | リフトマスタのストロークはどのくらい長く製作できますか? |

| A7 | 標準仕様のストロークは1500mmが上限ですが、昇降荷重・OHL条件を確認した上で2000mmまでご希望のストロークで製作可能です。 |

| Q8 | 据付方向は自由ですか? |

| A8 | 標準仕様は床面据付のみとなります。 |

| Q9 | 高速運転をしたいのですが、リフトマスタの最高スピードはどのくらいですか? |

| A9 | 標準仕様/U速の場合、三相モータ付では150mm/s、サーボモータ付では166mm/sが最大となります。 |

| Q10 | より低床化したい場合はどのような方法がありますか? |

| A10 | アームの下限位置を床面により近づけやすくするために、モータを上部に取付ける仕様も可能です。 |

| Q11 | リフトマスタで高頻度な運転をしたいのですが、運転頻度の制限はどのくらいですか? |

| A11 | 標準仕様のボールネジタイプの許容負荷時間率※は30%EDです。 |

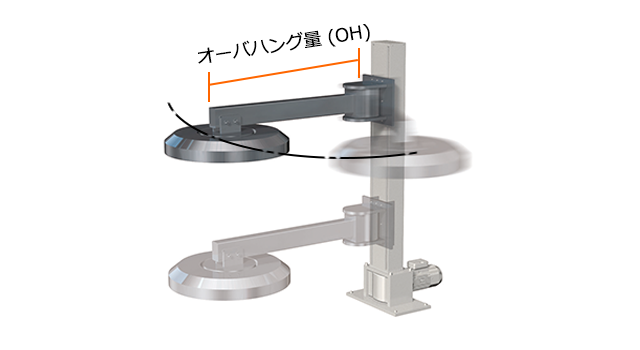

| Q12 | 重心位置がリフトマスタの正面に無い場合の許容OHLは? 重心位置がOHL荷重曲線より離れた場合も対応できますか? |

| A12 | 重心位置がオーバハング量の円弧内であれば、OHL荷重曲線より許容OHLを判断いただけます。 |

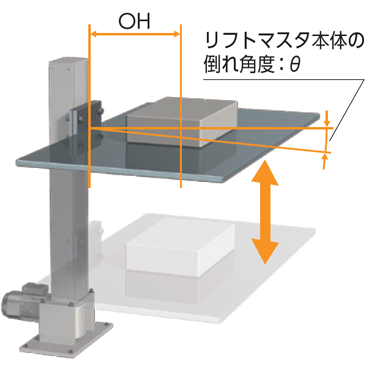

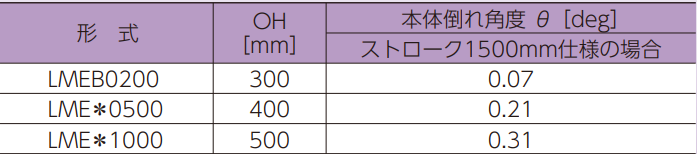

| Q13 | 定格荷重積載時におけるリフトマスタの倒れ量はどのくらいですか? |

| A13 | ストローク上限で許容OHLにおける倒れ量の参考値は下表になります。 |

| Q14 | リフトマスタの期待寿命はどのぐらいですか? |

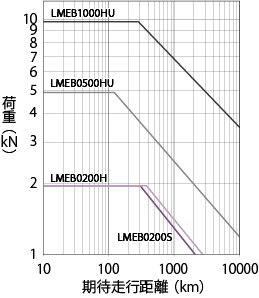

| A14 | リフトマスタの期待寿命はネジの期待走行寿命で判断します。 台形ネジタイプ(LMEM) 期待寿命は、昇降荷重にかかわらず、総走行距離が5kmに達した時点となります。(参考値)ボールネジタイプ(LMEB) ボールネジの寿命は、転動面の疲労による剥離により決まります。下記グラフで概略の寿命をご確認ください。ただし、衝撃が多い場合や、適切な潤滑・メンテナンスが行われていない場合は、期待走行距離が大きく低下します。 期待走行距離(km) = 実負荷ストローク(m) × 使用頻度(回/日) × 稼働日数 / 年 × 10-3 × 期待年数 期待寿命は、昇降荷重に応じて異なります。ストローク途中で荷重が大きく変動する場合は、等価荷重を以下の式にて算出してください。 PM = PMIN + 2 × PMAX3 PM : 等価荷重 N PMIN : 最小荷重 N PMAX : 最大荷重 N ・このグラフは、ボールネジのL10寿命(全体の90%以上が到達する寿命)を基に、走行距離として表したものです。・衝撃が多い場合や、適切な潤滑・メンテナンスが行われていない場合は、期待走行距離が大きく低下します。 ・長寿命を求められる場合は負荷条件に合わせたボールネジの変更も検討します。  |

| Q15 | リフトマスタの惰行距離、停止精度はどの程度ですか? |

| A15 | 下降時の惰行距離、停止精度の目安は以下の通りです。· LMEB0200H ... 惰行距離 : 約1.5mm / 停止精度 : 約±0.5mm |

| Q16 | DCモータ駆動 (バッテリ-電源) は対応できますか? |

| A16 | 使用条件によっては、対応可能です。 |

| Q17 | リフタサイズやストロークなどの特殊品は対応できますか? |

| A17 | 使用条件により、特殊対応が可能です。 |

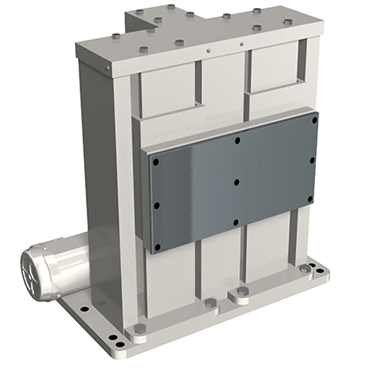

| Q18 | 高剛性仕様は対応可能ですか? |

| A18 | 使用条件により、特殊対応が可能です。 |

| Q19 | リフトマスタのサーボモータ駆動の対応は可能ですか? |

| A19 | ボールネジタイプLMEBでは、サーボモータ付を標準化しています。 質問へ戻る |

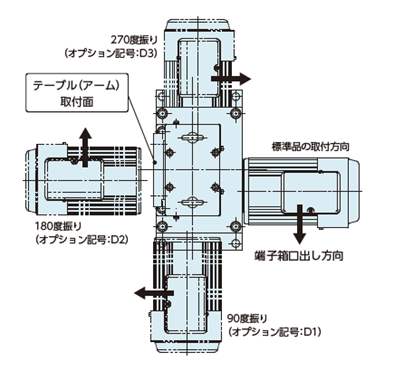

| Q20 | モータの取付位置・方向は、変更可能ですか? |

| A20 | モータの取付方向の変更はオプションにて対応しています。[オプション記号:D1~D3] |

| Q21 | 片持式リフタの位置検出センサを増やせますか? |

| A21 | オプションとして、位置検出センサ(オプション記号:[L1~L3])で対応しています。 |

| Q22 | ステンレス仕様は製作可能ですか? |

| A22 | カバーなど一部の部品 (強度部材以外) をステンレスに変更することは可能です。 質問へ戻る |

| Q23 | 特殊グリース (食品系、低発塵系) の対応可能ですか? |

| A23 | 対応可能です。『高速リフタ選定依頼フォーム』またはカタログ巻末のテクニカルシートに使用条件をご記入の上、お問合せください。 質問へ戻る |

| Q24 | モータの倍電圧は対応できますか? |

| A24 | オプションとして、モータ電圧400V級[オプション記号:V]で対応しています。 質問へ戻る |

| Q25 | ジャバラを後付できますか? |

| A25 | 後付けはできません。製品ご検討時にジャバラ要否を合わせてご検討ください。 質問へ戻る |

| Q26 | アームの製作は対応可能ですか? |

| A26 | 特殊対応が可能です。『高速リフタ選定依頼フォーム』またはカタログ巻末のテクニカルシートに使用条件をご記入の上、お問合せください。 質問へ戻る |

| Q27 | 耐熱仕様は対応できますか?その場合の耐熱温度は何度まで可能ですか? |

| A27 | 使用条件 (温度・運転頻度・負荷) により異なりますので、お問合せください。 質問へ戻る |

| Q28 | クリーン度の高い雰囲気で使いたいのですが対応できますか? |

| A28 | リフトマスタは開放構造のため、クリーン度は保証できませんが、各部品よりの発塵を低減する対応は可能です。· レイデント処理® (ボールネジ・ガイド) |

| Q29 | 屋外対応可能ですか? 水が掛かっても良いですか? |

| A29 | リフトマスタは屋内仕様ですので、水のかかる場所での使用は想定しておりません。 |

| Q30 | 耐寒仕様は対応できますか? |

| A30 | 使用条件により特殊対応が可能です。 |

| Q31 | 耐熱仕様のジャバラはありますか? |

| A31 | 耐熱仕様の対応はしておりません。 |

| Q32 | 非該当証明書の依頼方法を教えてください。 |

| A32 | 非該当証明書については、ご購入先を通じてご依頼ください。 質問へ戻る |