Q&A 機械式過負荷保護機器

お客様から寄せられました「よくある質問」をQ&A形式で掲載しています。質問をクリックして回答へお進みください。

ショックガード・ショックガードカップリング

Q&A内で語句を

| Q1 | RoHS対応状況は? |

|---|---|

| A1 |

TGB、TGXシリーズはすでに対応済みです。TGMシリーズにつきましては順次切り替え中です。 TGMシリーズでRoHS適合品が必要な場合は、ご発注時に「RoHS適合品」と指示してください。 質問へ戻る |

| Q2 | 許容温度範囲は? |

| A2 |

本体温度-10℃~100℃です。一部のカップリング仕様は80℃が上限となります。 この温度範囲外の場合は都度ご相談ください。 質問へ戻る |

| Q3 | 寿命について教えてください。 |

| A3 |

使用条件により異なりますので、明確にはお答えできません。 質問へ戻る |

| Q4 | TGMシリーズを水・油等がかかる環境で使用する際の注意事項はありますか? |

| A4 |

TGMシリーズはシールとパッキンによりケース内の部品にダスト、油、水が入りにくい構造となっておりますが、ケースから露出しているカム軸、調整ネジは水、水蒸気による腐食錆が発生しますので、ご注意ください。 質問へ戻る |

| Q5 | TGB30-Lを購入したが実機で確認するとトルク不足でした。TGB30-Hに変更したいのですが、どうすればよいですか? |

| A5 |

TGB30-LとTGB30-Hで違う部品はバネだけです。 バネを交換すればTGB30-Hになるのですが、製品に貼り付けている設定トルク調整用のトルク目盛が合わなくなります。 そのままご使用いただいても問題ありませんが、トルク目盛が必要な場合は一旦弊社へご返却いただき、皿バネ交換、min.ポイントにトルク設定、トルク目盛の貼り直しをして再出荷させて頂きますので最寄りの販売店までご相談ください。 質問へ戻る |

| Q6 | ショックガードを使用していましたが、過負荷になってもトリップしませんでした。その推定原因は? |

| A6 |

調節ナット(ボルト)等をを締め過ぎている可能性があります。 |

| Q7 | ショックガードカップリングを使用したいのですが、被動機側と駆動機側で取り付ける向きはあるのでしょうか? |

| A7 |

向きはありません。どちらに取り付けていただいてもご使用いただけます。 |

| Q8 | 高速軸に高精度なTGXを採用したいのですが、トリップ後に瞬時に停止することができません。何かよい方法はないでしょうか? |

| A8 |

ノンバックラッシで完全リリースが可能な特殊仕様品があります。 当社までご相談ください。 質問へ戻る |

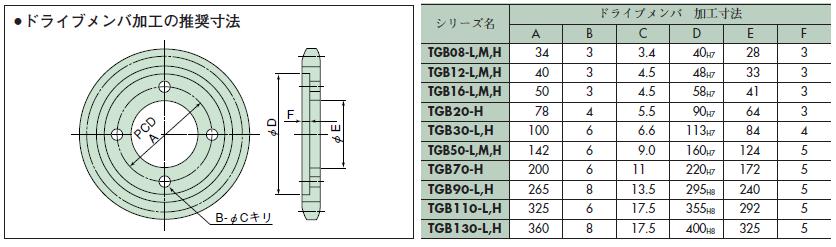

| Q9 | TGBシリーズにスプロケットを取り付けたいのですが、スプロケットの加工推奨寸法を教えてください。 |

| A9 | 質問へ戻る |