Q&A ドライブチェーン

お客様から寄せられました「よくある質問」をQ&A形式で掲載しています。質問をクリックして回答へお進みください。

Q&A内で語句を

ドライブチェーン

チェーン周辺機器

| Q1 | ステンレスドライブチェーンの品揃えと特長は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 |

ステンレス材は、一般的に耐食性、耐薬品性、耐熱性に優れた材料です。椿本チエインでは、このステンレス材の利点を生かした下記の様な品種を品揃えしており、食品機械業界を中心に様々な業界、用途でご採用頂いています。

※その他、内リンクにプラスチック材を、外リンクにステンレス材を使用した、無給油、軽量、低騒音の特長を兼ね備えたプラコンビチェーンも用意しております。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q2 | コーティングドライブチェーンのNP仕様、NEP仕様の違い、使分けは? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A2 |

ステンレスドライブチェーンは、スチールチェーンに比べ耐食性は優れますが、強度(最大許容張力)は1/8以下と低くなります。強度がスチールチェーン並みで、耐食性に優れたものを必要とされる用途では、コーティングドライブチェーンのNP仕様、NEP仕様を使用頂いています。(但し、ステンレスドライブチェーンのような耐食性はありません)

※強度比は、スチールを100とした概略値。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q3 | ラムダチェーンとはどの様なチェーンか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A3 |

チェーンの摩耗伸びを抑え、延命を図るには潤滑が必要不可欠です。

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q4 | 多列のラムダチェーンの製作対応は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A4 |

ラムダチェーンの発売当初は、1列のみを商品化しておりました。その後、2列についても多数のご要望を頂き、2001年 カタログに記載し商品化しました。但し、RSローラチェーンと寸法や伝動能力、最大許容張力が異なりますのでご注意ください。

※3列以上は性能上の問題から、ラムダチェーンでは製作できません。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q5 | ラムダチェーンに給油しても良いのか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A5 |

一般的にラムダチェーンは、給油したくない あるいは 給油できないアプリケーションに最適です。定期的な給油が可能であればRSローラチェーンの方が長寿命を期待できますので、RSローラチェーンをお奨めいたします。(ラムダチェーンでも適正な給油を行なうことで、下図の通り、更に延命が図れます。)

<給油の要領> ・給油サイクル 元々、ブシュに含油しているため、RSローラチェーン等に比べ、初回の給油の間隔は長くとれます。(但し、2回目以降の給油サイクルはRSローラチェーン等と同じです)効果的な給油の時期は、上図で伸びが急激に立ち上がる前(A点)になり、伸びが立ち上がってからでは給油してもさほど延命は図れません。プレート間から茶色い摩耗粉が発生すると、既にブシュの油切れの状態です。使用条件等により異なりますが、目安として1~3日に一度は給油を実施ください。 ・油種 鉱油や合成油であれば問題ありません。極圧型の作動油やギヤー油をお勧めします。 ・粘度 使用条件により異なりますが、一般的な目安は ISO VG68~220程度になります。 <新商品のご紹介> ラムダチェーンに比べ、更に寿命を延命した長寿命ラムダチェーンを商品化しております。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q6 | 低温で使用できるチェーンは? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A6 |

冷凍庫内など、チェーンを低温で使用される場合、

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q7 | 継手リンクのクリップ、割ピンの取付け方向は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A7 |

RS60以下の小形ローラチェーンの継手リンクにはクリップを採用しています。左図の如く、進行方向に対し、頭側を前側にして取付けてください。取付けの際には、クリップの脚を開けすぎない様に注意ください。

RS80~RS200及び3列以上の小形ローラチェーンでは、継手リンクに割ピンを採用しています。左図の如く、外側から割ピンを挿入し、60°程度開脚ください。割ピンの再使用や市販の割ピンは使用しないでください。 ※チェーン品種により継手リンクの取付け方法が異なります。詳しくはカタログを参照ください。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q8 | チェーンにはどのような潤滑油を使用すれば良いのか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A8 |

ローラチェーン伝動において、潤滑は非常に重要です。

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q9 | 駆動用ローラチェーンの潤滑にグリースは効果があるか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A9 |

チェーンの摩耗は、ピンとブシュ間(ピッチ伸びになります)、ブシュとローラ間、外プレートと内プレート間、及びスプロケットとローラ間で発生します。 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q10 | チェーンの摩耗寿命限界とは? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A10 |

(1)RSローラチェーンの場合

チェーンがスプロケット上で屈曲する際、ピンとブシュが摺動し、少しずつピン外周とブシュ内周の摩耗が進行します。 これがチェーンの摩耗伸びとなります。チェーンの摩耗伸びが進行すると、チェーンがスプロケット歯の山に登っていくようになり、ついには歯飛びを起こし、噛合い不能になります。

(2)ラムダチェーンの場合

ラムダチェーン及び長寿命ラムダチェーンは、0.5%位が寿命の目安となります。RSローラチェーンとは異なり、無給油で使用されるため、含油焼結ブシュの油切れが発生した時点が取替え時期となります。この油切れが発生する時期が 伸び量でいうと0.5%位となります。油切れになると、プレート間に赤い摩耗粉が付き、屈曲不良も発生しだしますので、これを目安に取替えてください。

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q11 | チェーンの初期伸びはどれぐらいか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A11 |

チェーンは運転開始後、組立歪と初期なじみにより伸びが急激に立ち上がります。これを初期伸びといい、その後、伸びは緩やかに進行します。初期伸び量は、通常0.1%程度ですが、当社のスチール製ローラチェーンのほとんどは、部品精度の向上、組立後のプレロードにより、初期伸び量を0.05%以下に押さえています。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q12 | どの様な場合にチェーンテンショナーを使用しなければならないのか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A12 |

(1)主な使用ケース

チェーンの過剰な弛み(タルミ)は、チェーンの振動、騒音を発生させ、チェーン及びスプロケット双方の寿命を低下させたり、歯飛びが生じたり、場合によっては思わぬトラブルに進展する場合があります。それを回避する為に テンショナが用いられます。テンショナは、張り過ぎに注意し、適度に張り調整することでチェーンの持っている伝動機能を長時間持続させる事ができます。

(2)使用上の注意

1. 一般的には、テンショナはチェーンの弛み側に配置ください。正逆運転が頻繁にある場合は、両側に配置が必要です。この場合テンショナに過負荷が作用しますのでご注意ください。当社のチェーンテンショナをご使用頂く場合は当社にご相談ください。 2. スパンの中央より、スプロケットの近くに配置した方がわずかの移動で調整量が大きく取れます。一般的には、小スプロケットの近くのチェーンの外側に設置します。そうすることで、小スプロケットへの捲き付け角も確保できます。 3. テンショナで押し付ける際は、互いのチェーン同士が接触しないよう注意ください。特に稼動中は、チェーンの脈動もありますので余裕を持たせて調整ください。 4. テンショナのスプロケットは、3歯以上噛合うようにしてください。 5. 一般的には、テンショナのスプロケット歯数は、小スプロケットと同歯数を推奨します。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q13 | チェーンの騒音の対策は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A13 |

チェーンがスプロケットに噛合う際、かならず騒音を発生します。その発生箇所は、以下の通りです。 <発生箇所>

1. (チェーンの)ローラがスプロケット歯底に衝突する際に発生する衝突音。 <対策> A.衝突エネルギーを減少させる。 ・チェーン速度を落とす。 ・スプロケット歯数を大きくする。 ・小サイズのチェーンを用い、質量を減少させる。 B.衝突部に緩衝効果を持たせる。 ・スプロケット歯底、チェーンの各部の隙間(プレート間、ピン-ブシュ間、ブシュ-ローラ間)に給油する。 ・エンプラ製ローラを使用する。 (伝動能力は低下します) ・スプリングローラを使用した、低騒音ドライブチェーンを使用する。RSローラチェーン(プレ給油品)に比べ、6~8dB低騒音化が図れます。(当社実験値比) 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q14 | ステンレスチェーンの最大許容張力はなぜ低いのか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A14 |

ステンレスチェーンの最大許容張力は、スチールチェーンに比べ約1/8程度に低下します。これは、許容張力の設定方法が下記の通り異なる為です。

〇RSローラチェーン(スチール製)

〇ステンレスドライブチェーン(SS仕様)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q15 | スプロケットの回転ムラの原因と対策は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A15 |

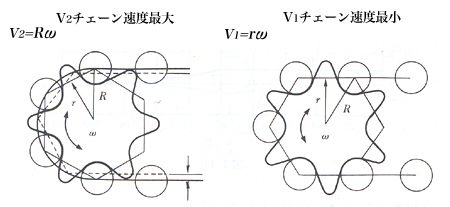

<チェーンの速度変動>

まず、回転ムラの原因のひとつとなるチェーンの速度変動についてご説明します。チェーンはスプロケットに対し、多角形的に噛合います。そのため、下図の通り円の接線位置で噛合う時と、弦の位置で噛合う時とでは、噛合いの高さ(スプロケット中心からの半径)が異なります。これにより、駆動スプロケットが等速回転していても、チェーンの進行速度は半径比だけばらつきます。その速度変動率は、次式にて計算されます。

<回転ムラ> チェーンの速度変動とスプロケットの性質とにより、従動スプロケットに回転ムラが生じます。更に、スプロケットの偏心取付誤差やチェーン及びスプロケットの製作誤差による影響も加わります。駆動スプロケットの歯数を増やせば(直径の大きなもの)、円滑な伝動に近づき、回転ムラは小さくなります。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q16 | ピンギヤ駆動とはどの様な方法か? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A16 |

物を直線運動や回転運動させるために、一般には駆動源(モータなど)より減速機を経て、ローラチェーンやギヤなどが使用されます。

上表よりピンギヤ駆動は、

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q17 | ローラチェーン、ラムダチェーンの弾性伸び量は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A17 |

〇RSローラチェーン 1列 標準的な目安として下表を参照ください。

〇ラムダチェーン 1列

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

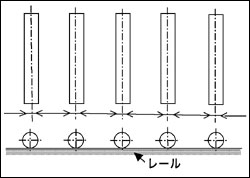

| Q18 | 多連ロール(ローラコンベヤ)の駆動方式とその特長は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A18 |

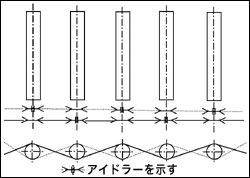

多連ロール(ローラコンベヤ)には、ワンモータ駆動やラインシャフト駆動がありますが、ここではチェーンを使用した一般的な3パターンの駆動方式を紹介します。 (1)平行掛式 〇方式 〇長所 〇短所

(2)ラック式 〇方式 〇長所 〇短所

(3)たすき掛式 〇方式 〇長所 〇短所

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q19 | チェーンにはどの様な規格があるのか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A19 |

チェーンはいろいろな用途に幅広く用いられる機械要素であり、性能と互換性を確保するために、国際規格と各国規格が制定されています。以下にその一部を紹介いたします。(2007年1月現在)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q20 | チェーンはRoHS指令に対応しているか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A20 |

椿本チエインの伝動用・搬送用チェーンはRoHS指令に全て対応しております。

RoHS指令(ローズ指令)とは

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q21 | オフセットリンク(OL)の種類と注文方法は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A21 |

チェーンを奇数リンクで編成される場合にはオフセットリンク(半こま)が必要です。 (1) オフセットリンク(OL)の種類

(2) 2POL、4POL手配時の注意点 全長9リンクで2POLをご使用になりたい場合の編成 ●例:MCJLと2POLを使用 全長9Lの場合

全長11リンクで4POLをご使用になりたい場合の編成 ●例:FSJLと4POLを使用 全長11Lの場合  質問へ戻る

質問へ戻る

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q22 | 継手リンク(JL,OL,2POL)を組込む際に給油は必要か? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A22 |

本体に組込んで出荷を行なう場合を除き、継手リンクには通常軽防錆油のみを塗布し発送しています。これはお客様で切り継ぎされる際、本体と同等粘度の潤滑油を継手リンクに塗布すると作業性を低下させる恐れがあるためです。継手リンクを出荷された状態のままご使用いただいくと、早期に給油不足による 摩耗が発生する恐れがあります。 継手リンクを本体に組み込む際にはピン、ブシュに必ず潤滑油を塗布してから本体に組み入れてください。既にピン・ブシュが組み込み済みの2POLは下図を参考に給油してください。 ※2POLの給油位置  質問へ戻る

質問へ戻る

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q23 | ローラチェーン(ドライブチェーン)は、過去に呼称名が変更されたことがあるか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A23 |

1966年以降、大幅なローラチェーンのチェーンサイズを示す呼称名は変更していません。ただし、仕様、ラインナップの拡大により商品名の追加はありますので、各商品ページをご確認ください。 なお、現商品は当時の商品とは形状同一なものの、大幅に性能が向上しています。当時の設計資料や、取替えの際は当社へご相談ください。

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q24 | F形継手リンクとM形継手リンクの違いは? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A24 |

継手プレートのピン穴とピンがすきまばめかしまりばめかの違いです。 M形継手リンク … すきまばめ F形継手リンク … しまりばめ ・連結作業やメンテナンスでの着脱作業がスムーズにできるのは ・吊下げ、サイドフォースが作用するおそれがある場合の伝動は

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q25 | チェーンテンショナ(椿本製)の使用上の注意は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A25 |

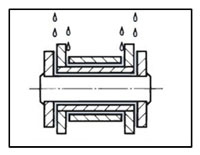

(1)チェーンが脈動すると、反動でテンショナのロッドが出入りして、本体との間で摺動します。その為、ロッドおよび本体側で摩耗が促進されますので、この間に給油を実施ください。 (2) 粉塵や腐食性の激しい雰囲気では、テンショナの損傷が激しくなります。その様な雰囲気では、ご使用を避けてください。 (3) 垂直駆動のようにテンショナにスラスト方向の力が加わり、且つ正逆運転のように激しい荷重変動が加わる場合は、テンショナが著しく損傷する場合がありますので、ご使用を避けてください。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q26 | チェーンテンショナの変位量と押し付け力の関係は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A26 |

つばきチェーンテンショナの本体部には、2本のコイルばねを内蔵しており、このコイルばねの弾性を利用して、先端部に取付けたアイドラスプロケットまたはプラスチックシューがチェーンを押付け、たるみを調整する機構です。以下に、アイドラスプロケットまたはプラスチックシューの変位量とその時に作用する押付け力の関係式を示します。据付け、調整時の目安としてください。 ◆TCS形(揺動式) ・作用する押付け力 F(kN) 〇CT-TCS40、CT-TCS50 〇CT-TCS60、CT-TCS80

◆ETS形及びTA形(直動式) ・作用する押付け力 F(kN) 〇CT-ETS40、CT-ETS50、CT-TA40 〇CT-ETS60、CT-ETS80、CT-TA50、CT-TA60

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q27 | ローラチェーン用自動給油器(SFM68)を上向きで使用できるか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A27 |

ローラチェーン用給油器(SFM68)本体にオプションのブラシを使用される場合は、上向きに設置すると、油がブラシ先端まで届きません。水平より下向きになる方向で使用ください。ブラシを使わず、配管される場合は、給油器本体の向きは、下向き・上向き・横向きなどレイアウトは自由です。但し、配管の長さは0.5m未満、内径6mm以上とし、経路の分配は行わないでください。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q28 | ローラチェーン用自動給油器(SFM68)に充填された食品機械用油とは? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A28 |

ローラチェーン用給油器(SFM68)に充填された潤滑油は、FDA(米国食品医薬品局)連邦規則21CFR178.3570※1に合格し、NSF(米国国立公衆衛生財団)によりH1※2認定を受け、安全性が確認された潤滑油です。お客様のPL対策やHACCP※3(ハセップ)システムにおいて「安全性の向上」に貢献します。 〇安全性 〇潤滑油の性能(潤滑性・極圧性・耐熱性・酸化安定性・防錆性他) ※1偶発的に食品に接触する潤滑剤を「間接食品添加物」と位置づけており、厳しい安全性試験の結果、潤滑剤を構成してもよい物質及びその許容濃度を細かく規定している。 ※2 FDAで認可された原材料を使用し、「偶発的に食品に接触する可能性のある潤滑箇所に使用できる」として認定された食品機械用潤滑剤のことです。H1以外にH2もあり、H2は「食品に接触する可能性はないが、食品工場で使用すること が望ましい潤滑剤」とされています。つまり、食品に触れる可能性がある場所での使用はできません。 ※3 HACCPはHazard Analysis Critical Control Pointの略で、「危害分析重要管理点」と訳され、安全・衛生管理手法です。 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q29 | ローラチェーン用自動給油器(SFM68)でON、OFF操作が頻繁に出来るか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A29 |

ローラチェーン用給油器(SFM68)のスイッチであるガスジェネレータ(乾電池式ガス発生器)でON、OFFは可能です。 [ガスジェネレータは、製造から3年の寿命です。長期間機械を停止される場合、これを越えない様にご注意ください。詳細は、カタログ、取扱説明書に記載しております。] 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q30 | チェーンの摩耗伸びを簡単に測定できないか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A30 |

通常、チェーンの摩耗伸びの測定には、ノギスやコンベックスを利用し、どの程度伸びているかを点検いただきます。RSローラチェーン、BSローラチェーン、リーフチェーンに関しては、簡易的に寿命に達しているかどうかを判定する「チェーン摩耗測定スケール」を商品化しております。(伸び量は測定できません。) 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q31 | エンドボルトの特型は対応できるのか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A31 |

吊下げ等で使用頂く為の端末金具「エンドボルト」は、カタログではRS40EB~RS120EBまでです。しかし、ご要望によりそれ以外のサイズも特型で対応いたします。弊社までご相談ください。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q32 | チェーン分解用の簡単な治具はあるか? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A32 |

チェーンの分解は、グラインダ、バイス、パンチをご用意頂ければ、あとは一般的な工具で対応できます。当社では、より簡単で使い易いチェーン専用の分解工具も商品化しております。詳しくは、ドライブチェーンアクセサリの頁をご覧ください。 質問へ戻る |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q33 | エンドボルトへの荷重の方向は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A33 |

水平(台車けん引、ピンギヤなど)あるいは垂直(吊り下げなど)で使用いただく際は、エンドボルトの軸芯上にローラチェーンの荷重が作用するようにしてください。エンドボルトの軸芯とローラチェーンの作用荷重方向が異なる使い方(曲げ荷重が作用するような使い方)や捩じりが作用するような使い方は、絶対にしないでください。その他、カタログに記載のご使用上の注意を参照ください。  質問へ戻る

質問へ戻る

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q34 | スプロケットの心出し方法は? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A34 |

スプロケットの取り付けの良否は、チェーンのスムーズな伝動・搬送に影響するだけでなく、チェーン・スプロケットの寿命も左右します。 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

良い

良い