トラブルシューティング ローラチェーンの伝動の異常とその手当

全般

| 1 | ローラチェーンがスプロケットに乗り上げる |

|---|---|

| 2 | 異常な騒音がする |

| 3 | ローラチェーンが振動する |

| 4 | ローラチェーンがスプロケットに巻込む(噛離れが悪い) |

| 5 | ローラチェーンの発錆 |

| 6 | ローラチェーンのプレートの内側とスプロケット歯側面の摩耗 |

| 7 | ローラチェーンのプレート側面やピン頭部の摩耗 |

| 8 | ローラチェーンの屈曲が悪い |

| 9 | プレート内幅の広がり |

プレート関係

| 10 | プレートが破断する |

|---|---|

| 11 | プレートにクラックが発生(疲労) (引張方向に直角方向) |

| 12 | プレート穴の変形 |

| 13 | 応力腐食割れ(プレートに弓状のクラック) |

ピン関係

| 14 | ピンが破断する |

|---|---|

| 15 | ピンの回転または飛び出し |

| 16 | 金具などに接続したときの継手ピンのみに摩耗や錆が発生する(吊下げなど) |

ブシュ・ローラ関係

| 17 | ローラ・ブシュが割れる(脱落) |

|---|---|

| 18 | ローラが回転しない |

| 19 | ローラが開口する |

| 20 | ローラがつづみ形になる |

全般

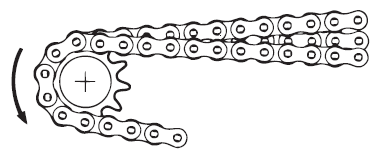

| 1 |

[クリックで拡大] |

ローラチェーンがスプロケットに乗り上げる |

|---|

| 原因1 | ローラチェーンとスプロケットが不適合 | 手当法 | ローラチェーンまたはスプロケットを正しいサイズに取替える。 |

|---|---|---|---|

| 原因2 | 著しい過負荷 | 手当法 | 負荷を減少させる(被動機に給油なども)。またはローラチェーンサイズや列数を増やすか、サイズを大きくする。 |

| 原因3 | ローラチェーンの摩耗伸びまたはスプロケットの歯の摩耗 | 手当法 | 新品に取替える。 |

| 2 | 異常な騒音がする |

|---|

| 原因1 | スプロケットや軸の据付不良 | 手当法 | 点検・修正をする。 |

|---|---|---|---|

| 原因2 | チェーンケーシングや軸受の緩み | 手当法 | 全てのボルト・ナットを締めなおす。 |

| 原因3 | ローラチェーンのたるみ量の過大・過小 | 手当法 | 最適のたるみになるように軸間距離を調整する。 |

| 原因4 | ローラチェーンまたはスプロケットの著しい摩耗 | 手当法 | 一連のローラチェーン・スプロケットを新品に取替える。 |

| 原因5 | 無給油または給油不適当 | 手当法 | 使用条件に合った給油をする。 |

| 3 | ローラチェーンが振動する |

|---|

| 原因1 |

ローラチェーンが外力の周期と共振 |

手当法 |

ローラチェーンの振動モードを替える。 1.共振を防ぐ方法 a. ローラチェーンの固有振動数を変える。 ○初期張力を与える、あるいは変更することによって有効張力を変更する。 ○テンショナを付けてチェーンスパンを変更する。 ○ローラチェーンを変更する。(質量・バネ定数の変更) b. 起振振動数を変える。 ○スプロケットの回転速度を変更する。 ○装置の見直しをする。 2.機械的に振動を小さくする。 ○振止め(ガイドストッパ)を付ける。 ○たるみ側に自動調整式テンショナを付ける。 |

|---|---|---|---|

| 原因2 | 負荷の変動が異常に大 | 手当法 | 流体継手などで変動を少なくする。 |

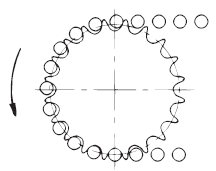

| 4 |

[クリックで拡大] |

ローラチェーンがスプロケットに巻込む(噛離れが悪い) |

|---|

| 原因1 | 軸間距離が長すぎる | 手当法 | 中間にアイドラを入れる。 |

|---|---|---|---|

| 原因2 | ローラチェーンのたるみ量が過大 | 手当法 | チェーン長さまたは軸間距離を調整する。 テンショナを付ける。 |

| 原因3 | ローラチェーンの摩耗伸び、またはスプロケットの摩耗 | 手当法 | いずれも新品と交換する。 |

| 5 | ローラチェーンの発錆 |

|---|

| 原因1 | 不適当な給油、悪い雰囲気 | 手当法 | ローラチェーンを取替えた後で、給油やケーシングによって雰囲気からローラチェーンを保護する。 |

|---|

| 6 | ローラチェーンのプレートの内側とスプロケット歯側面の摩耗 |

|---|

| 原因1 |

据付不良 |

手当法 | スプロケット、軸などの据付修正をする。 |

|---|

| 7 | ローラチェーンのプレート側面やピン頭部の摩耗 |

|---|

| 原因1 |

ガイドなどの据付不良 |

手当法 | ガイドの状態をチェックし、ガイドとローラチェーンの隙間を広くする。 |

|---|

| 8 |

[クリックで拡大] |

ローラチェーンの屈曲が悪い |

|---|

| 原因1 | 据付不良によるローラチェーンの変形 | 手当法 | 据付状態の点検・修正をする。 |

|---|---|---|---|

| 原因2 | 不適切な給油(例えばグリース)による摩耗粉、ゴミなどの固着 | 手当法 | ローラチェーンを外し、洗浄・適切な給油をする。 |

| 原因3 | 著しい過負荷、ピンの曲り、ブシュ割れ | 手当法 | 負荷を減少させる、またはローラチェーンサイズや列数を増やす。 |

| 原因4 | 腐食・錆 | 手当法 | ケーシングを付けてローラチェーンを保護する。 |

| 原因5 | 不適切な給油による焼付き | 手当法 | 使用条件に合った潤滑をする。 |

| 原因6 |

ピンとブシュの焼付き 高速運転によって、ピンとブシュが焼付き、屈曲不良を起こし、切断事故を引起こすこともある。 |

手当法 | 使用条件を適切にする。 |

| 9 | プレート内幅の広がり |

|---|

| 原因1 |

据付不良による偏荷重または著しい過負荷 |

手当法 | 新品に取替えると共に据付の修正をする。 |

|---|

プレート関係

| 原因1 | 過大な衝撃荷重 | 手当法 | 起動・停止をスムーズにするなどによって衝撃荷重を小さくする。(緩衝装置を付けるなど) ローラチェーンのサイズを大きくする、または列数を多くする。 |

|---|---|---|---|

| 原因2 | ローラチェーンの振動 | 手当法 | 振動を防止する装置を付ける。(テンショナ、アイドラなど) (ローラチェーンが振動する)の項を参照 |

| 原因3 | 被動機械の慣性大(過負荷) | 手当法 | ローラチェーンを改めて再選定する。(ローラチェーンのサイズを大きくする、または列数を多くする。) |

| 原因4 | 腐食 | 手当法 | 新品に取替える。ケーシングを付けてローラチェーンを保護する。また定期的にローラチェーンを洗浄し給油する。 |

| 11 | プレートにクラックが発生(疲労) (引張方向に直角方向) |

|---|

| 原因1 | 最大許容張力よりも大きな負荷が作用 | 手当法 | 過負荷・過大繰返し荷重を除く、またはローラチェーンのサイズを大きくするか、列数を多くする。 |

|---|

| 12 |

[クリックで拡大] |

プレート穴の変形 |

|---|

| 原因1 | 過負荷 | 手当法 | 新品に取替える。過負荷の要因を除く。 |

|---|

| 13 |

[クリックで拡大] |

応力腐食割れ(プレートに弓状のクラック) |

|---|

| 原因1 | 酸・アルカリ性雰囲気での使用 (繰返し荷重の影響ではない。) |

手当法 | 新品に取替える。ケーシングなどによって雰囲気からローラチェーンを保護する。 応力腐食割れに抵抗性の高い仕様の検討。(当社にご相談ください。) |

|---|

ピン関係

| 原因1 | 大きな衝撃荷重 | 手当法 | 衝撃を弱め、起動・停止をスムーズにする。 |

|---|---|---|---|

| 原因2 | ピンの疲労限を越える繰返し荷重 | 手当法 | 過大繰返し荷重を除く、またはローラチェーンのサイズを大きくするか、列数を多くする。 |

| 原因3 | 腐食 | 手当法 | ケーシングを付ける。定期的にローラチェーンを洗浄し給油する。 |

| 15 |

[クリックで拡大] |

プレート穴の変形 |

|---|

| 原因1 | 過負荷または給油不足 | 手当法 | 新品に取替える。過負荷または給油の改善をする。 |

|---|---|---|---|

| 原因2 | 高負荷で給油不良の場合に、ピンとブシュに異常な摩擦力が発生し、瞬時にピンが廻ることがある。この状態で運転すると、ピン抜けによってローラチェーンが破壊する。 | 手当法 | 直ちに新品に取替える。このときピンを溶接したり、古いピンの再使用はしないでください。(古いローラチェーンは誤って再使用しないように破棄してください)また、ピン頭部やプレート側面が摩耗しているときは、据付状態を点検してください。 |

| 16 | 金具などに接続したときの継手ピンのみに摩耗や錆が発生する(吊下げなど) |

|---|

| 原因1 | 取付時の初期給油の不良 | 手当法 | 継手リンクを取替える。ピンの摩耗が著しいときはローラチェーンも取替える。 取付けるときは、特に吊下げ用などの端末金具の接続部に注意してください。 |

|---|

ブシュ・ローラ関係

| 17 | ローラ・ブシュが割れる(脱落) |

[クリックで拡大] |

疲労破壊 運転中に疲労が進み遂に破壊したもの。伝動能力以上の力でスプロケットの歯面にたたかれて起きる。 |

|---|

| 原因1 | 回転速度または負荷の過大 | 手当法 | 伝動能力表によって選定を再度行う。 |

|---|---|---|---|

| 原因2 | 不適切な給油 | 手当法 | 使用条件に適切な給油をする。新品に取替える。 |

| 18 | ローラが回転しない |

|---|

| 原因1 | RS11-SS-1、RS15-1、RS25-1、RS35-1 | 手当法 | ブシュドチェーンでローラはありません。 |

|---|---|---|---|

| 原因2 | 内プレートが内側に寄っている、またはブシュ割れ | 手当法 | 新品に取替える。据付の再点検、負荷のチェック |

| 原因3 | 輸送物・異物がブシュとローラ間に入る。 | 手当法 | 定期的な排除。ケーシングを取付けてローラチェーンを保護する。 |

| 19 | ローラが開口する |

|---|

| 原因1 |

過負荷 |

手当法 | 負荷を減少させる。適切な給油をする。 |

|---|

| 20 | ローラがつづみ形になる |

|---|

| 原因1 | 過負荷または、給油不足 | 手当法 | 新品に取替える。過負荷または給油の改善をする。 |

|---|