トラブルシューティング トップチェーン

チェーン及びスプロケット等に異常があった場合は、まずカタログ技術ノート、据付・点検に従って点検をお願いします。

異常の発生個所・症状をご確認の上、以下の手当を行ってください。

異常の発生個所・症状をご確認の上、以下の手当を行ってください。

コンベヤ装置

| 1 | 異常騒音 キーキー、カタカタ |

|---|---|

| 2 | 脈動 |

チェーン

| 3 | チェーン搬送面の異常な摩耗 |

|---|---|

| 4 | チェーン裏面の異常な摩耗や傷 |

| 5 | チェーン側面の異常な摩耗 |

| 6 | チェーンの屈曲が硬い |

| 7 | チェーンの破断や破損 |

| 8 | チェーンの変色 |

コンベヤ周辺・部品

| 9 | レール沿いや駆動スプロケット下に摩耗粉が溜まる |

|---|---|

| 10 | チェーンの歯飛びや噛合い不良 |

搬送品

| 11 | コンベヤ乗移り部などで製品が転倒する |

|---|

コンベヤ装置

| 1 | 異常騒音 キーキー、カタカタ |

|---|

| 原因1 | チェーンが安全カバーやフレーム等を叩いている。 | 対策 | 騒音の所在を突き止めて、接触しないように修正する。 |

|---|---|---|---|

| 原因2 | チェーンがレールのガイドクリアランスの狭い箇所を走っている。 | 対策 | 狭い部分を突き止め、レールの温度膨張や変形の関連をチェックし、修正する。 |

| 原因3 | レールの表面仕上げが粗かったり、寸法や材質が不適当である。 | 対策 | 表面仕上げ、寸法精度、適切な材質のレールに交換する。 |

| 原因4 | チェーンの進行方向が反対。 | 対策 | チェーンの裾付をやり直す。 |

| 原因5 | 潤滑が不十分だったり、使用条件が過酷すぎる。 | 対策 | 潤滑液や潤滑方法などを修正する。 |

| 2 | 脈動 |

|---|

| 原因1 | リターンローラの位置・間隔やカテナリーカーブの位置・大きさが不適当である。 | 対策 | カタログ技術ノートを参考にし、スムーズなリターン走行が得られるように、不適切な箇所を修正する。 |

|---|---|---|---|

| 原因2 | アイドラローラやリターンローラがスムーズに回転していない。 | 対策 | スムーズに回りやすいように軸受仕様にしたり、径を大きくするなどの対策をとる。 |

| 原因3 | レールのガイドクリアランスの狭い箇所がある。 | 対策 | 狭い部分を突き止め、レールの温度膨張や変形の関連をチェックし、修正する。 |

| 原因4 | レール上に付着している異物が滑りを阻害している。 | 対策 | 異物を取り除くなど、レールを清掃する。 |

| 原因5 | レール端のシャープエッジや障害物に引っ掛かっている | 対策 | シャープエッジを滑らかにしたり、障害物を除去する。 |

| 原因6 | 潤滑が不十分だったり、使用条件が過酷すぎる。 | 対策 | 潤滑液や潤滑方法などを修正する。 |

チェーン

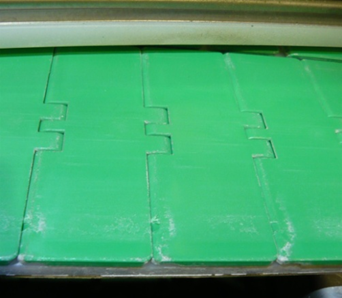

| 3 |

[クリックで拡大] |

チェーン搬送面の異常な摩耗 |

|---|

| 原因1 | リターンローラが回転していない。 | 対策 | リターンローラの径を大きくしたり、仕様を変更する。 |

|---|---|---|---|

| 原因2 | リターン入口Rが小さかったり、リターンローラの径が小さすぎる。 | 対策 | カタログ技術ノートを参照し、修正する。 |

| 原因3 | 戻り側レールの表面仕上げが粗かったり、配置や材質が不適当である。 | 対策 | 表面仕上げ、適切な材質のレールをチェーン幅に均一に接触するよう配置する。 |

| 原因4 | 摩擦を促進するざらつきがリターンローラやレールに付着。 | 対策 | コンベヤを清掃する。発生原因を突き止め対策をとる。 |

| 原因5 | ガイドレールや障害物がキズ付けている。 | 対策 | 障害物を突き止め、修正する。 |

| 4 | チェーン裏面の異常な摩耗や傷 |

|---|

| 原因1 | 搬送側レール上に異物が付着したり、埋まっていてチェーンをキズ付けている。 | 対策 | 異物を取除き清掃する。 |

|---|---|---|---|

| 原因2 | 搬送側レールの表面仕上げが粗い。 | 対策 | 表面仕上げを修正したり、適切なレールに交換する。 |

| 原因3 | アイドラホイールとの接触痕。 | 対策 | 必要があればスプロケットに交換する。 |

| 5 | チェーン側面の異常な摩耗 |

|---|

| 原因1 | レールもしくはスプロケットの位置が不適当。 | 対策 | 位置を修正する。 |

|---|---|---|---|

| 原因2 | カーブドプラレールの表面仕上げが粗かったり、材質が不適当である。 | 対策 | 表面仕上げ、材質の適切なレールに交換する。 |

| 原因3 | 潤滑が不十分だったり、カーブ使用条件が過酷過ぎる。 | 対策 | 潤滑方法などを修正する。 |

| 6 | チェーンの屈曲が硬い |

|---|

| 原因1 | ピンやリンクが過負荷などで曲がったりカジリが生じている。 | 対策 | 硬直箇所を取除くか、新しいチェーンに取替える。 |

|---|

| 7 | チェーンの破断や破損 |

|---|

| 原因1 | 異物や障害物が引っ掛った。 | 対策 | 異物や障害物を取除く。 |

|---|---|---|---|

| 原因2 | 薬品や高温による劣化や腐食による脆性破壊。 | 対策 | 原因を突き止め使用条件を変更するか、チェーンの仕様を変更する。 |

| 原因3 | チェーンがスプロケットを乗り越えた。 | 対策 | チェーンの摩耗伸びが原因なので、チェーンを交換する。 |

| 原因4 | 使用条件が厳しく衝撃的な過大な張力が掛かった。 | 対策 | 原因を突き止め、対策をとる。 |

| 原因5 | プラグが脱落している。 | 対策 | プラグの状態を確認する。新品と交換する。 |

| 8 | チェーンの変色 |

|---|

| 原因1 | 汚れが付着。 | 対策 | 洗浄する。 |

|---|---|---|---|

| 原因2 | 薬品、高温、紫外線などによる劣化。 | 対策 | 使用条件を確認し、適切な仕様のチェーンに交換する。 |

コンベヤ周辺・部品

| 9 | レール沿いや駆動スプロケット下に摩耗粉が溜まる |

|---|

| 原因1 | カーブドプラレールなどの表面仕上げが粗い。 | 対策 | カーブドプラレールの材質グレードを変更する。 |

|---|---|---|---|

| 原因2 | レール端のシャープエッジや障害物がチェーンを削っている。 | 対策 | エッジを滑らかにする。 |

| 原因3 | 不十分な潤滑。 | 対策 | 適度の潤滑をする。 |

| 原因4 | ざらつきの存在。 | 対策 | 発生原因を突き止め、対策をとる。 |

| 10 | チェーンの歯飛びや噛合い不良 |

|---|

| 原因1 | チェーンが過度に伸びている。 | 対策 | チェーン、スプロケットを交換する。 |

|---|---|---|---|

| 原因2 | スプロケットの歯底に異物がたまっている。 | 対策 | 異物を取除き、清掃する。 |

| 原因3 | スプロケットの位置がずれている。 | 対策 | 取付けをやり直す。 |

| 原因4 | 不適当なスプロケット(破損、変形、膨潤、腐食)。 | 対策 | 原因を究明し、仕様を再確認する。必要に応じ交換する。 |

| 原因5 | 分割形スプロケットのハブ周辺の破損。 | 対策 | スプロケットのボルトの緩み、締め込み過ぎを確認する。交換時適正な締付トルクでボルトの締め付けを確認する。 |

搬送品

| 11 | コンベヤ乗移り部などで製品が転倒する |

|---|

| 原因1 | ガイドレールやの位置や形状、チェーンのレベル、速度比、滑り不足。 | 対策 | ガイドの角度を緩やかにする。ガイドの位置の変更。速度、潤滑の修正。レベルの確認。必要に応じて変更する。 |

|---|