トラブルシューティング ケーブルベヤ

| 1 | 本体リンクが破損した |

|---|---|

| 2 | ケーブルが断線した |

| 3 | ロングスパン仕様の本体リンクが破損した |

| 4 | ケーブルベヤ内でケーブル・ホースが捩れ、絡み合う |

| 1 |

|---|

| 原因1 |

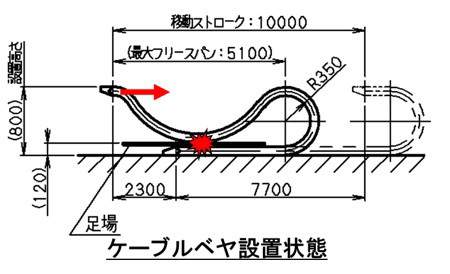

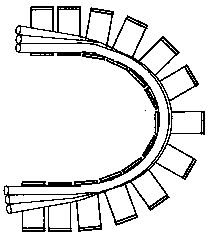

フリースパン部のたわみにより(1)・(2)の影響を受けて過大な衝撃力が作用した。

|

手当法 |

※適用品種はこちらをご確認ください。 |

|---|---|---|---|

| 原因2 | 稼働にともない耐久寿命に達した。 | 手当法 | フリースパン部のたわみ量の限界値(目安)と比較し、限界値に達している場合は、新品に交換する。 |

| 2 |

|---|

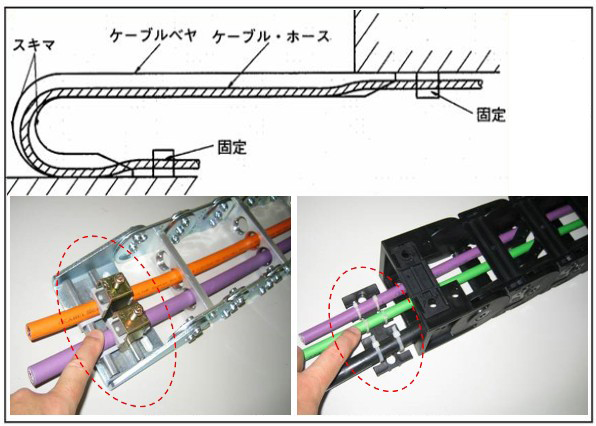

| 原因1 | ケーブル・ホースがケーブルベヤ内外周へにじり出し、周辺装置に干渉した。 | 手当法 | |

|---|---|---|---|

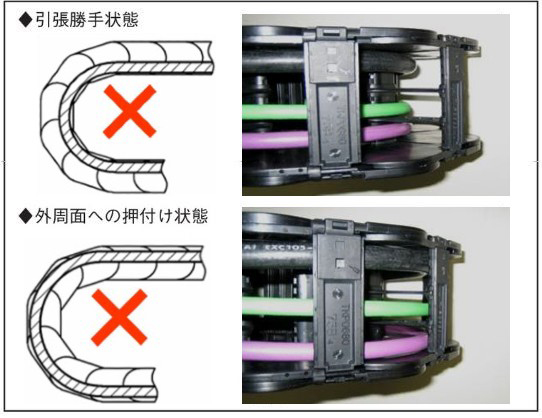

| 原因2 |

内周側のケーブル・ホースが押しつぶされ過度な圧縮力が繰り返し作用した。 |

||

| 原因3 | ケーブル・ホースの許容屈曲半径よりケーブルベヤの屈曲半径が小さいために負荷がかかった。 | 手当法 | ケーブルベヤの屈曲半径をケーブル・ホースの許容屈曲半径より大きくする。 |

| 3 |

|---|

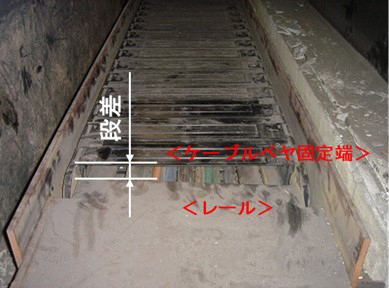

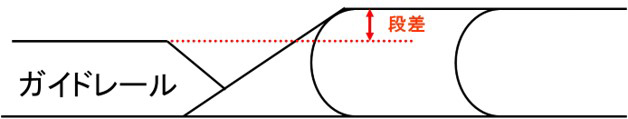

| 原因1 |

ケーブルベヤ内周面がスライド走行するレールと、ケーブルベヤ固定端リンクとの継ぎ目部における段差が大きかった。 それにより、レールから固定端リンクへの乗り継ぎ時のスライド抵抗が増幅された。 |

手当法 |

ガイドレールとケーブルベヤとの段差をなくす。 詳細は取扱説明書をご覧ください。 |

|---|---|---|---|

| 原因2 |

ケーブルベヤの移動端・設置高さが弊社推奨値よりも高かった。 それにより、フリースパン部に過大な曲げモーメントが作用した。 |

手当法 | 設置高さを弊社推奨値内とする。 |

| 原因3 | ケーブルベヤ走行面に積もった粉塵などにより、走行抵抗が増した。 | 手当法 |

粉塵の蓄積を避ける。

|

| 4 | ケーブルベヤ内でケーブル・ホースが捩れ、絡み合う |

|---|

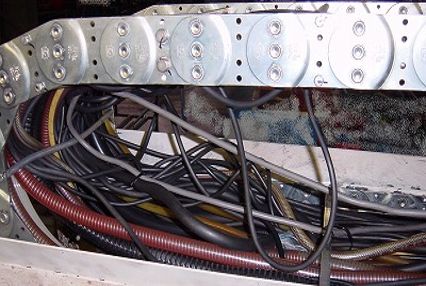

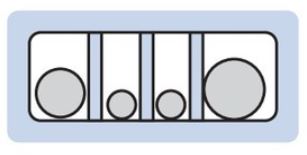

| 原因1 |

仕切板を用いて、ケーブル・ホースを区分けしていなかった。 |

手当法 | 仕切板を取り付け、できるだけ1空間1本となるようにケーブル・ホースを収納する。 |

|---|---|---|---|

| 原因2 | 移動用のケーブルを使用していないため心線の撚りが戻り、ケーブルが蛇行したような状態となった。 | 手当法 | 柔軟性に富み、繰返し屈曲性・耐久性に優れた移動用のケーブル ・ホースを使用する。 |