トラブルシューティング スプロケット・ピンギヤドライブ

スプロケット

| 1 | チェーンがスプロケットに乗り上げる |

|---|---|

| 2 | 異常な騒音がする |

| 3 | チェーンがスプロケットに巻込む(噛み離れが悪い) |

| 4 | チェーンのプレート内側とスプロケット歯側面の摩耗 |

| 5 | スプロケット歯底、歯押面の摩耗 |

| 6 | 屈曲不良 |

| 7 | チェーンがスティック・スリップ(シャクリ現象)を起こす。 |

| 8 | NFブロックチェーンやBFチェーン(ローラなし)の内リンクやピンの片方が摩耗する。 |

| 9 | プレートの急進破壊 |

| 10 | ハブの破損 |

| 1 | チェーンがスプロケットに乗り上げる |

|---|

| 原因1 | チェーンとスプロケットが不適合 | 手当法 | チェーンまたはスプロケットを正しいサイズに取替える。 |

|---|---|---|---|

| 原因2 | チェーンの摩耗伸びまたはスプロケットの歯の摩耗 | 手当法 | 新品と取替える。 |

| 原因3 | 巻付角の不足 | 手当法 | 120°以上または3歯以上の巻付角とする。 |

| 原因4 | チェーンとスプロケットの心間距離 | 手当法 | 点検後、修正する。 |

| 2 | 異常な騒音がする |

|---|

| 原因1 | スプロケットや軸の据付不良 | 手当法 | 点検・修正をする。 |

|---|---|---|---|

| 原因2 | チェーンまたはスプロケットの著しい摩耗 | 手当法 | 一連のチェーン・スプロケットを新品に取替える。 |

| 原因3 | 無給油または給油不適当 | 手当法 | 使用条件に合った給油をする |

| 3 | チェーンがスプロケットに巻込む(噛み離れが悪い) |

|---|

| 原因1 | チェーンの摩耗伸び、またはスプロケットの摩耗 | 手当法 | チェーンとスプロケットを新品に取替える。 |

|---|

| 4 |

|---|

| 原因1 | 据付不良 | 手当法 | スプロケット、軸などの据付修正をする。 |

|---|---|---|---|

| 原因2 | チェーンが横方向に押される | 手当法 | 押される原因の除去、ガイドローラ付チェーンに変更する。 |

| 原因3 | スプロケットの心出し不良 | 手当法 | チェーンをはずして駆動、従動スプロケットの心出しを修正する。 |

| 原因4 | スプロケットの軸穴加工精度不良による振れ | 手当法 | 不良箇所をチェック後、修正して新しいスプロケットに取替える。 |

| 原因5 |

キーの位相が合っていない |

手当法 |

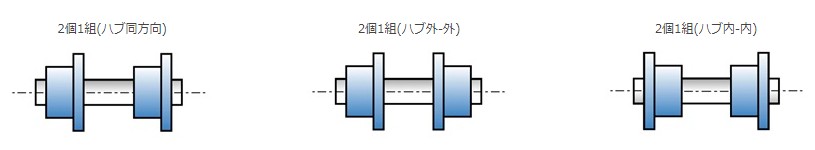

同軸上に2個以上で並列使用の場合はスプロケット歯を同位相にする。 取付け時のハブ方向を確認し、キー溝位置を合わせる。組み合わせたスプロケット同士は合マークを打ち管理する。 |

| 5 | スプロケット歯底、歯押面の摩耗 |

|---|

| 原因1 | チェーンの摩耗 | 手当法 | チェーンとスプロケットを同時に取替える。 |

|---|---|---|---|

| 原因2 | 噛み合い歯数不足 | 手当法 | スプロケットの歯数を増やす。 |

| 原因3 | BFチェーン(ローラなし)使用 | 手当法 | RFチェーン(ローラ付)へ変更する。 |

| 原因4 | 摩耗介在物や過大荷重に対して歯部の硬さ不足 | 手当法 | 歯先硬化仕様やブロック替歯タイプを使用する。 |

| 原因5 | スプロケットとチェーンの不適合 | 手当法 | チェーンまたはスプロケットを正しいサイズに取替える。 |

| 6 | 屈曲不良 |

|---|

| 原因1 | 据付不良によるチェーンの変形 | 手当法 | スプロケット、軸の据付状態を点検し修正する。 |

|---|

| 7 | チェーンがスティック・スリップ(シャクリ現象)を起こす。 |

|---|

| 原因1 | チェーンの転がり摩擦係数の変動 | 手当法 | スプロケットを新品に取替える。 |

|---|---|---|---|

| 原因2 | 多角形運動による速度ムラ | 手当法 | 駆動スプロケット歯数を12T以上とする。 |

| 8 | NFブロックチェーンやBFチェーン(ローラなし)の内リンクやピンの片方が摩耗する。 |

|---|

| 原因1 | スプロケットとの噛み合い時の内部張力が増加する。 | 手当法 |

|---|

| 9 | プレートの急進破壊 |

|---|

| 原因1 | 手当法 |

|

|---|

| 10 |

|---|

| 原因1 | ハブ強度不足 | 手当法 | ハブ径・軸穴径の確認、修正して新しいスプロケットに取替える。 |

|---|

スプロケットはチェーンと一緒にお使いいただくことで、はじめて製品として機能します。

それぞれのチェーンのトラブルシューティングページも用意していますので、併せて参照ください。