Q&A スプロケット

お客様から寄せられました「よくある質問」をQ&A形式で掲載しています。質問をクリックして回答へお進みください。

Q&A内で語句を

スプロケット全般

ドライブチェーン用RSスプロケット

小形コンベヤチェーン用スプロケット

大形コンベヤチェーン用スプロケット

| Q1 | スプロケットの選定はどのように検討すればよろしいでしょうか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 |

使用するチェーンの形番・スペックを考慮したスプロケットを選定する必要があります。 基本的な手順は下記となります。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q2 | スプロケットに使用する主な材料を教えてください。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A2 |

当社で使用しているスプロケット材料の主なものは下表となります。 カタログ掲載品で下表のラインアップがない製品は、見積り・受注生産にて製作いたします。お問合せください。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q3 | スプロケットに使用されるステンレス材にはどんなものがありますか? また歯先硬化処理(焼入れ)ができるものはありますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A3 |

ステンレス製スプロケットに用いられる材料を下表に紹介します。ご参照ください。 カタログ掲載のステンレス仕様スプロケットは、オーステナイト系ステンレス鋼(SUS304系)を使用しており、材質の特性上、歯先硬化処理(焼入れ)を行うことができません。 ステンレス鋼で歯先硬化処理をご要望の場合は、マルテンサイト系ステンレス鋼(SUS420系)にて製作が可能です。(見積り・受注生産品) また、表面処理を施して硬度をあげた高強度ステンレスチェーン推奨スプロケットもご提案できます。(見積り・受注生産品) ご要望がございましたらお問合せください。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q4 | スプロケットとチェーンをステンレス製とスチール製の組合せで使用した場合、問題がありますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A4 |

同材質での使用を推奨しております。ステンレススプロケットはステンレスチェーンとの組合せを前提にラインアップしております。 例えばステンレス製チェーンとスチール製スプロケットめっきタイプを組合わせて使用すると電位差腐食(電食)をおこし早期に摩耗する場合があります。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q5 | カタログに『歯先硬化処理』とありますが、スプロケットにどのような処理を行っているのでしょうか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A5 |

カタログに記載している「歯先硬化処理」とは、高周波焼入れを行って表面を硬化させる処理です。 歯部に焼入れを行うのは耐摩耗性と強度の向上にあり、一般的に回転数が高い場合(単位時間当たりのチェーン噛合い回数が多い)や、歯数が少なく巻付け角度が少ない場合、摩耗介在物が存在する場合に歯先硬化処理を行います。 歯先硬化処理を行う材質としては、一般的には機械構造用炭素鋼を用いますが、ご用命により構造用合金鋼でも可能です。 焼入処理の一種であることから、『歯先硬化処理あり=焼入れ仕様』、『歯先硬化処理なし=生仕様』ともいいます。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q6 | スプロケットの各部名称を教えてください。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A6 |

スプロケット各部の名称は下記の通りです。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q7 | スプロケットに標準付属の「止めねじ」とはどんなねじですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A7 |

当社スプロケットの標準止めねじ仕様は「六角穴付き止めねじ(くぼみ先)」です。 フィットボア以外の標準スプロケット、特形スプロケット(見積り・受注生産品)は基本的に付属していません。 本体がステンレスタイプもしくはメッキ仕様のものはステンレス製の止ねじを付属いたします。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q8 | スプロケットの形状はどんなものがありますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A8 |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q9 | A形スプロケットのみを購入して、ハブを溶接しようと思います。問題はありますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A9 |

A形スプロケットへのハブ溶接は、溶接の熱により品質保持ができなくなる可能性があります。 お客様ご自身での溶接は避け、当社へご相談ください。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q10 | 発注後にレイアウト上、スプロケットのハブ径が干渉することが判りました。ハブを加工しても大丈夫でしょうか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A10 |

お客様による追加工が原因で、破損などの事故となる恐れがありますので推奨しておりません。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q11 |

カタログの「下穴」とはどういう意味でしょうか? 軸穴の寸法はカタログの「下穴径~最大軸穴径の範囲」で製作できるということでしょうか? |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A11 |

下穴とは、スプロケットを製作する過程で必要な穴で、基本的には軸組付けに相応しい公差の穴であけていません。 下穴径より+1mm以上~最大軸穴径までの範囲において、適切な公差で製作が可能です。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q12 | スプロケット軸穴は最大でどこまでの大きさの加工が可能ですか。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A12 |

標準下穴タイプ軸穴加工で、カタログにて各形番歯数ごとに記載している寸法表の「最大軸穴径」以下としております。 最大軸穴径の記載がないA形スプロケットにつきましては、製作検討しますので当社までご相談ください。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q13 | 最大軸穴径を超えた穴径で使用するとどうなりますか?ハブの厚みが薄いと何か問題はありますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A13 |

ハブ厚みはスプロケット強度に影響し、不足するとクラックや破損の原因となります。 チェーン使用条件からスプロケットが破損しないよう十分な強度を考慮したハブ径・軸穴径の設計としてください。 また、当社にはサイズを変更することなくハブ強度をアップした強力チェーン推奨スプロケット TOUGH TOOTH をご用意しています。 ハブ強度が不足する、スペース的にハブサイズが変更できない場合等にご検討ください。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q14 | スプロケットの歯とキー溝加工の位置関係はどのようになっていますか? 指定は可能でしょうか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A14 |

ご指定がない場合、キー溝は下記位置に加工しております。

※キー溝加工位置に精度が必要な場合、または、特定の歯位置と合わせる場合は指示が必要になります。 ご要望の際は『位相合わせ』や『並列使用』などの指示が必要です。 ※『位相合わせ』 : 「Q15.スプロケットの歯とキー溝の位置関係を指示する加工はできますか?」参照。 ※『並列使用』 : 「Q16.同軸上で複数のスプロケットを使用時、キー溝の相対的な位置関係はどのようになっていますか?」参照。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q15 | スプロケットの歯とキー溝の位置関係を指示する加工はできますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A15 |

特形として可能です。 『位相合わせ』としてキー溝加工位置を「歯先」または「歯底」のどちらの中心に合わせるかご指示ください。 通常、つばきではドライブチェーン用・バイピッチ用では歯底の中心に、大形コンベヤチェーン用では歯先に合わせています。 合わせる精度は目視程度となります。具体的な基準がある場合はご相談をお願いします。 ※複数のスプロケットを同軸上でご使用される場合で特に精度が必要な場合には『並列使用』のご指示が必要です。 ※『並列使用』 : 「Q16.同軸上で複数のスプロケットを使用時、キー溝の相対的な位置関係はどのようになっていますか?」参照。歯先合わせ

歯底合わせ

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

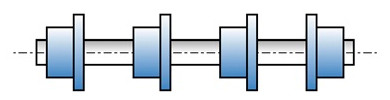

| Q16 | 同軸上で複数のスプロケットを使用時、キー溝の相対的な位置関係はどのようになっていますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A16 |

基本的に考慮しておりません。相対的なキー溝の位置関係を考慮する必要がある場合は『並列使用』とご指示ください。 その際は下記2点をご確認いただきご指示ください。合わせる精度は目視程度となります。

※キー溝と歯の位置関係を合わす『位相合わせ』とは異なります。位相合わせが必要な場合は別途ご指示ください。 ※『位相合わせ』 : 「Q15.スプロケットの歯とキー溝の位置関係を指示する加工はできますか?」参照。2個1組(ハブ同方向)

2個1組(ハブ外-外)

2個1組(ハブ内-内)

4個1組(3個同方向)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q17 | フィットボアとはどんな商品ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A17 |

「フィットボア」とは「軸穴完成済スプロケット」です。 「Fit=適合する、bore=穴を開ける」という意味で、カタログ掲載のサービス範囲内から仕様をセレクトいただき、「軸穴加工、キー溝加工、タップ穴加工」の軸穴加工を施してお客様にすぐにご使用できる状態でお届けします。 「当社指定の軸穴加工完成済みの在庫品」、「お客さまに選択いただいた内容で軸穴加工を施す受注生産品」があります。 軸穴加工仕様は、TT-netの図面ライブラリより、1億通り以上の選択肢からお選びいただくことが可能です。

フィットボアはスプロケット以外にタイミングプーリもご用意しています。

質問へ戻る

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q18 | スプロケットにベアリングを組込んでの納入は可能ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A18 |

仕様や条件によってはお断りさせていただくこともありますが、製作可否を検討させていただきます。お問合せください。

質問へ戻る

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q19 | ロックスプロケットとはどんなスプロケットですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A19 |

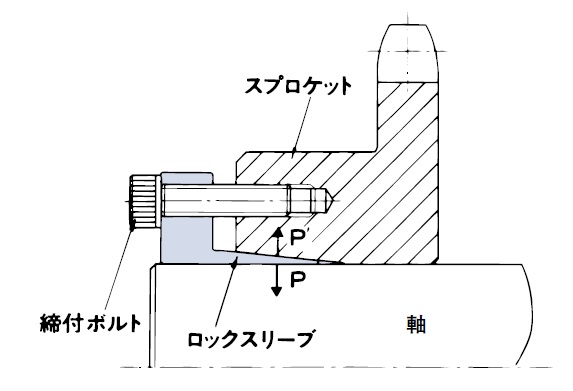

ロックスプロケットはキーを使わずスプロケットと軸を締結する摩擦締結仕様のスプロケットで下記の特長があります。

ボルトの締付けに際しては、必ずトルクレンチを使用してください。 適切なトルクで正しく取付けされていないとスプロケットが滑って回転します。 軸径公差 h8 軸表面粗さ Rq3.2を基準としてください。 その他、注意事項はカタログ、取扱説明書にてご確認のうえ、正しく使用してください。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q20 | ロックスプロケットで、軸径インチサイズは製作可能ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A20 |

ロックスプロケットはインチ系を設定しておりません。 つばきパワーロックにはインチ系の設定品がありますのでパワーロックのご利用をお願いします。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q21 | キー溝加工が施されている軸にロックスプロケットを使用できますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A21 |

一般的なキー溝形状が施された軸であればご使用いただけます。 しかしながら許容伝達トルクが約10%小さくなりますのでご注意ください。 ロックスリーブと軸の接触面積がキー溝分減少するためです。 また、つばきパワーロックをご使用の場合でも同様に許容伝達トルクが小さくなります。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q22 | キー溝加工が施されている軸にパワーロックでスプロケットを取付けしても大丈夫ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A22 |

一般的なキー溝形状が施された軸であればELシリーズ以外のシリーズはご使用いただけます。 しかしながら許容伝達トルクが約10%小さくなりますのでご注意ください。 パワーロックと軸の接触面積がキー溝分減少するためです。 また、ロックスプロケットをご使用の場合でも同様に許容伝達トルクが小さくなります。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q23 | ロックスプロケットを検討しています。ロックスプロケットに表面処理は可能ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A23 |

表面処理の内容にもよりますが見積品、受注生産にて対応しております。

質問へ戻る

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q24 | ステンレス製のロックスプロケットはありませんか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A24 |

ステンレス製のロックスプロケットはラインアップしておりません。 摩擦締結式でステンレスタイプをご要望の場合は、つばきRSスプロケット(ステンレス仕様)に、つばきパワーロック(ステンレス仕様)の組み合わせを推奨いたします。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q25 | 表面処理はどのような処理が可能ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A25 |

表面処理とは、金属の表面に熱処理や化学反応を加え、外観の良さだけでなく耐食性、耐摩耗性を向上させる目的で実施します。 当社にて実施している代表的な表面処理は以下の3つです。 (※サイズにより制約がありますのでご要望の際はお問合せください)

また強力チェーン推奨スプロケット「TOUGH TOOTH」は表面硬さHV800以上とする処理もあります。 基本的にめっきは軸穴内径は処理されていません。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q26 | スプロケットにめっき処理を施したいのですが、注意すべき点は何ですか。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A26 |

強度低下などの要因となる場合もありますので、購入後にお客様にて製品への表面処理をされることは推奨しておりません。

質問へ戻る

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q27 | つばき無給油チェーン「ラムダチェーン」にはどんなスプロケットを選べばいいですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A27 |

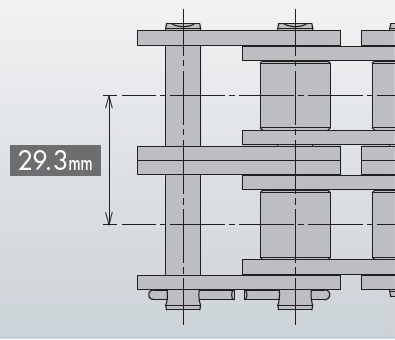

2列以上の選定はチェーン横ピッチサイズにご注意ください。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q28 | シャーピン付のスプロケットは製作可能ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A28 |

寸法と破断強度を当社にて仕様を決めかねます。詳細条件をご提示いただけない場合は、申し訳ございませんが品質保証面の問題でお断りさせていただいております。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q29 | スプロケットはRoHS指令に対応していますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A29 |

当社スプロケットは全てRoHS指令に対応しております。証明書がご入用の場合は、該当商品をお求めいただいた販売店経由で発行依頼をお願いします。 ※RoHS指令は改定されることがあります。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q30 | スプロケットの写真を送るので仕様を特定していただけますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A30 |

外観だけで特定などはできませんので写真で仕様特定をすることはできません。 申し訳ございませんがお断りをさせていただいております。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q31 | スプロケット現品があります。送付して同じものを製作して頂くことは可能ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A31 |

見積依頼にて仕様特定のお手伝いをさせていただくことは可能です。 ただ、現品を確認いたしましても仕様の特定に至らない場合もあります。 また見積りを回答いたしましても仕様につきましての責任は負いかねますのでご了承をお願いします。 使用品ならば新品の形状を留めておりませんので細かな寸法の仕様特定は困難ですし、痛みが激しい場合はおおまかな仕様特定すらできない場合があります。 材料におきましても特定できない場合もあります。 仕様の最終決定は当社見解を参考としてお客さまにてご決定いただけます様、お願いしています。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q32 | スプロケットの保管で注意することを教えてください。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A32 |

ほこりや塵、直接雨のかかるところ、高温、凍結、腐食雰囲気環境下で保管をしないでください。 錆の発生を防止するため刷毛で塗油をお願いします。 特に塗装のないもの、あっても軸穴などの塗装をしていないところは念入りにお願いします。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q33 | スプロケット駆動潤滑としてグリースは効果がありますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A33 |

スプロケットとチェーンの噛合い部において低速・高荷重ではグリース塗布が有効な場合もあります。 ただし、粉塵の多い場所などでは粉塵を吸着し固着させ、摩耗を促進させてしまう原因となることがあります。 また、チェーンは摩耗伸びを抑えるためにピンとブシュ間への給油が重要です。 チェーンに給油したオイルが外的要因(風雨など)で流れ出すのを抑制するためにグリースを塗布することもありますが、逆にグリースがチェーンのピンとブシュ間への給油を妨げてしまうと給油効果が低下する場合もありますので、十分に考慮いただきますようお願いいたします。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q34 | チェーンが摩耗したので新しく取替えを予定しています。スプロケットの外観は綺麗なので、そのまま使えるか気になっています。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A34 |

外観の綺麗さではスプロケットの摩耗は判断できません。 チェーンと同様にスプロケットも摩耗していますので、カタログや取扱説明書に記載の点検方法にて摩耗などの異常がないか、点検・確認を実施してご判断をお願いいたします。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q35 | スプロケット歯面の摩耗が早い気がします。なにか原因は考えられますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A35 |

スプロケット歯面(歯底、歯押面)の摩耗について予想される原因と手当方法を下表にまとめていますので、ご確認ください。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q36 | スプロケット歯の側面が摩耗しています。どんな原因が考えられますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A36 |

予想される原因と手当方法を下表にまとめております。 また、チェーンリンクプレート内側の摩耗も考えられます。チェーンも併せて点検ください。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q37 | チェーンがスプロケットにのり上げる時があります。どんな原因がありますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A37 |

予想される原因と手当方法を下表にまとめています。 放置しておくとプレートの急進破壊(図2)につながりますので必ず点検、対策を行ってください。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

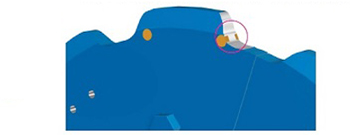

| Q38 | チェッカーズアイとはどんなものですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A38 |

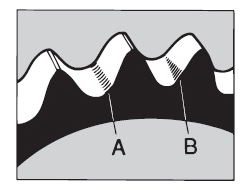

チェッカーズアイは 取替お知らせマークです。 (特許取得済) 歯部の摩耗限界点にマーキングを施しており、摩耗がそのマークにかかれば使用限界の寿命と判断します。 下記メリットがあります。

一目で取替時期を確認でき点検時間・工数の大幅削減可能です。 スキルがなくとも誰でも的確な寿命判断が可能です。 触手点検から目視点検へ。最低限の接触で点検の安全性が向上します。 大形コンベヤチェーン用スプロケット スマート取替シリーズ ならびにドライブチェーン用RSスプロケット大形サイズに搭載していますが、ご要望によってその他のスプロケットにも搭載することが可能です。 従来の点検

摩耗部と歯形ゲージの隙間を測定 チェッカーズアイによる点検 スプロケットの取替タイミングを一目で判定できます。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q39 | 点検が簡単なスプロケットはありませんか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A39 |

取替時期が一目でわかるチェッカーズアイ(取替お知らせマーク)搭載スプロケットをご用意しています。 取替頻度が高いスプロケットのスマート取替シリーズ(分割タイプ・リング替歯タイプ・プロック替歯タイプ)に標準搭載。 チェッカーズアイ搭載の標準スプロケットは「つばきブルーカラー塗装」として識別しています。 ドライブチェーン用スプロケット大形サイズに搭載の他、ご要望によってその他のコンベヤチェーン用スプロケットも搭載することが可能です。 ※『チェッカーズアイ』 : 「Q38.チェッカーズアイとはどんなものですか?」参照。チェッカーズアイによる点検 スプロケットの取替タイミングを一目で判定できます。

180°毎に2カ所の搭載

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q40 | スプロケットを購入するにはどこに発注すればいいですか? 納期はどのくらいかかりますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A40 |

当社では直接の販売を行っておりませんのでお取引のある代理店・販売店へお問合せをお願いいたします。 納期のご相談も併せてお問合せください。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q41 | ドライブチェーン用のスプロケットの歯形はどのような規格ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A41 |

つばきRSスプロケットの歯形には、JIS規格のS歯形を採用しています。(一部にJIS規格のU歯形も併用しています。) その他として、BS歯形や重荷重チェーン用あるいはピンギヤ用等の特殊歯形があります。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q42 | スプロケットの選定時に歯の強度計算は必要ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A42 |

歯の強度は一般にチェーンの最大許容張力以下であれば、歯が曲がったり折れたりすることはありませんので、カタログにラインアップしているものから選定してください。 ただし、強力形のチェーンでは考慮の必要があり、専用スプロケットも併せてご確認ください。 計算上は巻き付け伝動での各歯の張力分布が複雑なため1歯で計算しますが、実際には巻き付け伝動上、数歯でチェーン張力を分担することになるため、チェーンの張力を1歯のみで受けないことになります。 歯の荷重分担

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q43 |

ドライブチェーン用のスプロケットはどのようなときに『歯先硬化処理』が必要なのでしょうか? カタログ製品の『歯先硬化処理あり』と『歯先硬化処理なし』はどのような理由で決まっていますか? |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A43 |

ドライブチェーン用は下記の使用条件に該当するスプロケットに歯先硬化処理を実施しています。

質問へ戻る

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q44 | スプロケットの寿命はどこのメーカーも同じでしょうか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A44 |

メーカーにより異なります。主に歯部が摩耗することにより寿命に至りますが、当社では歯部は耐摩耗性に注力した『歯先硬化処理』を実施しています。 一般的な高周波焼入れですが、他社と比較しても深く均一な熱処理で長時間の使用において歯の摩耗に差が出ます。 『硬化処理』はつばき製品の強みです。耐摩耗性において優位性を持っているつばきスプロケットをご検討ください。

歯先硬化処理の断面比較(歯先変色部が硬化層)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q45 | スプロケットの使用可能温度範囲を教えてください。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A45 |

RSスプロケットの使用温度範囲は-10℃~150℃、RSスプロケットステンレス仕様の使用温度範囲は-20℃~400℃が適切となります。 温度による強度変化だけでなく、チェーン潤滑油による制約も考慮する必要があります。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q46 | 耐寒ドライブチェーンを使用する環境(-10℃以下)で、一般的な標準RSスプロケットは使用可能ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A46 |

カタログ記載の標準スプロケットは、機械構造用炭素鋼または圧延鋼を使用しており-10℃以下の低温下でご使用の際は、強度低下が発生しますので推奨しておりません。 受注生産品の材質に変更した特形スプロケットなどで対策のご提案ができる場合もございます。 カタログに記載のない使用温度範囲の製品につきましてはお問合せください。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q47 | 強力ドライブチェーンに一般的な標準RSスプロケットは使用できますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A47 |

歯先硬化処理が施された標準スプロケットであれば使用可能ですがキー面圧など不足する場合が多々あります。 強力ドライブチェーン推奨スプロケットとして「TOUGH TOOTH」をご用意していますのでご検討ください。 チェーンが強力となればなるほどキー面圧などのチェックが重要です。 ダブルキーやハブを長くして面圧をかせぐことができますが、スペースセービング、価格の観点より、ハブ強度を高くした「TOUGH TOOTH」を推奨いたします。 また、HT強力チェーンやスーパHチェーンなどH級のチェーンを多列で使用する場合は、歯部横ピッチが異なるため、標準RSスプロケットは使用することができません。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q48 | BS規格チェーンに標準RSスプロケットは使用できますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A48 |

JIS規格品であるRSスプロケットとは、基本3寸法(ピッチ・ローラ径・ローラリンク内幅)が異なるため使用できません。 BS規格チェーンには、BS/DIN規格専用スプロケットをご用意しております。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q49 | ピンギヤに標準RSスプロケットは使用できますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A49 |

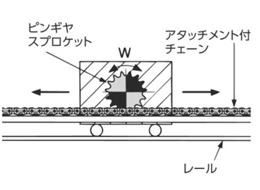

特殊歯形の専用スプロケットが必要です。 チェーンとの噛み合いが巻掛け伝動と異なるため、標準RSスプロケットはご使用できません。 物を直線運動や回転運動させるために、一般には駆動源(モータなど)より減速機を経て、ローラチェーンやギヤなどが使用されます。 ローラチェーンを使用した巻掛け伝動ではスペースが大きく、ギヤでは精密加工を要し、コスト高になるなどの問題に直面します。 このような時にピンギヤ駆動が最適です。 ピンギヤ駆動は、図1のようにホイールの代わりにピンギヤ用アタッチメント付チェーンをドラムやテーブルの外周に巻付け、ピニオンギヤの代りに特殊歯形のスプロケット(ピンギヤスプロケット)を用います。 また、直線運動の時は、図2のようにラックの代りにピンギヤ用アタッチメント付チェーンを直線に取付けます。 ピンギヤとホイールまたはラックをセットにしたユニット商品『ピンギヤドライブユニット』も販売中です。

[図1]

[図2] |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q50 | チェーンテンショナは製作可能ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A50 |

当社にてテンショナ・アイドラーを標準化してご用意しております。当社仕様よりご検討をお願いいたします。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q51 | スプロケットの回転ムラの原因と対策は? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A51 |

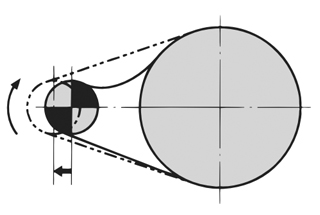

回転ムラの原因のひとつとなるのはチェーンの速度変動です。チェーンはスプロケットに対し、多角形的に噛合います。 そのため、下図の通り円の接線位置で噛合う時と、弦の位置で噛合う時とでは、噛合いの高さ(スプロケット中心からの半径)が異なります。 これにより、駆動スプロケットが等速回転していても、チェーンの進行速度は半径比だけばらつきます。その速度変動率は、次式にて計算されます。 速度変動率=(V2-V1)/V2=1-cos(180°/Z) (Zは歯数) 歯数が増すほど回転が滑らかになり、スムーズな伝動が可能となるため、一般的に歯数は15枚以上を推奨しております。 V2チェーン速度最大 V1チェーン速度最小

<回転ムラ> チェーンの速度変動とスプロケットの性質とにより、従動スプロケットに回転ムラが生じます。 更に、スプロケットの偏心取付誤差やチェーン及びスプロケットの製作誤差による影響も加わります。 駆動スプロケットの歯数を増やせば(直径の大きなもの)、円滑な伝動に近づき、回転ムラは小さくなります。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q52 | ドライブチェーンが振動しています。スプロケットが原因になることはあるのでしょうか?また、その対策はあるのでしょうか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A52 |

スプロケットが原因になることもあります。原因と対策は次のようになります。 多角形運動 コーダルアクション(スプロケットとチェーン多角形運動による上下運動)が関わっている場合、出来るだけ大きな歯数を選択することで多角形運動を抑制することは可能です。一般的に歯数は15歯以上を推奨しています。 ※『コーダルアクション』 : 「Q51.スプロケットの回転ムラの原因と対策は?」参照。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q53 | ドライブチェーン用RSスプロケットの適当な速比と巻付角はどのくらいまでですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A53 |

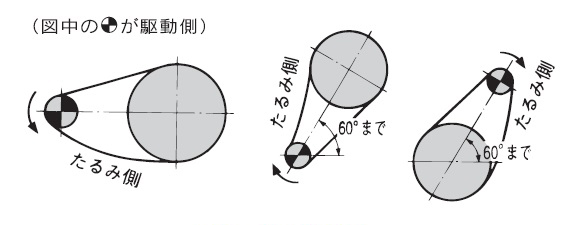

ローラチェーン伝動の速比は、普通7:1までが適当です。ごく低速の場合に限り10:1程度までは可能です。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q54 | ドライブチェーン用RSスプロケットのスプロケット軸間距離はどのくらいが適当ですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A54 |

最短距離は、2つのスプロケットの歯が接触しなければ結構です。最も好ましい両軸の中心距離は、使用するローラチェーンのピッチの30~50倍程度が理想的です。ただし、変動荷重のかかる時は20倍以下が適当です。 ローラチェーンのピッチの30~50倍程度

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q55 | ドライブチェーン用RSスプロケットのレイアウト配置に決まりはありますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A55 |

一般的なローラチェーン伝動の配置は下記の通りです。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q56 | ドライブチェーン用RSスプロケットで特に注意を要するレイアウト・配置はありますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A56 |

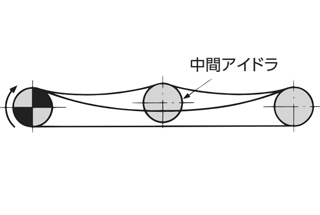

下記のような場合はレイアウト・配置に注意が必要です。アイドラ・テンショナのご使用をお願いいたします。

図1) 中心距離が短い場合のレイアウト

図2) 中心距離が長い場合のレイアウト

図3) 垂直伝動 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q57 | ドライブチェーン用RSスプロケットの取付精度と取付手順を教えてください。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A57 |

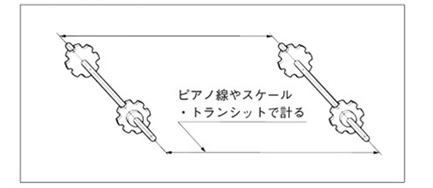

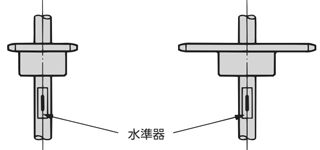

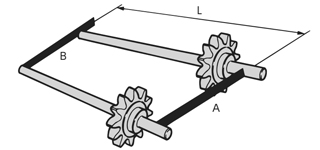

取付は水平度、平行度に注意して下記の要領で正しく行ってください。

図1) 軸の水平度

図2) 軸の平行度

図3) スプロケットの食違い |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q58 | ドライブチェーン用RSスプロケットはどうなれば寿命ですか?点検のポイントを教えてください。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

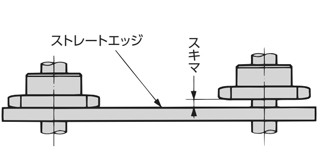

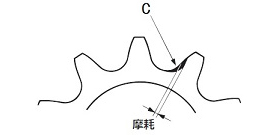

| A58 |

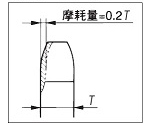

寿命・取替えの目安は歯の摩耗を確認します。スプロケットは歯が摩耗することにより強度が低下、チェーン伝動に悪影響を与えます。 定期的な点検により不具合が出る前に新しいスプロケットに取替えてください。確認のポイントは下記になります。

点検の工数削減、安全性向上として、取替え時期が判るチェッカーズアイを搭載したスプロケットの製作が可能です。 歯厚の使用限界・B寸法表

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q59 | ドライブチェーン用RSスプロケットの据付不良の症状と点検のポイントを教えてください。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A59 |

【症状】 下記のような症状があった場合にはスプロケットおよびその据付を再度、ご確認ください。

【点検ポイント】 スプロケットの噛み合いの点検から要因を判断できます。 正常でない場合は再点検・修正をしてください。

異常の原因はスプロケットの取付不良か、ローラチェーンがねじれているなどになります。 異常が認められた際、そのままのスプロケットではローラチェーン伝動に悪影響を与えますので新しいスプロケットに取替えてください。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q60 | バイピッチSローラ用に、ドライブチェーン用のRSスプロケットが使用できますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A60 |

バイピッチSローラには歯数29歯以下のRSスプロケットは使用できず、バイピッチスプロケットが必要です。 歯数30歯以上の場合にはドライブチェーン用標準RSスプロケットが使用可能です。 (※これは歯数30歯以上でピッチ円直径=P.C.Dが近似値となるためです) また、多列においてRF2060以上のサイズは横ピッチが異なるため使用できません。この場合は特形チェーンに該当しますのでチェーン図をもとにスプロケットも特形で製作を検討いたします。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q61 | 小形コンベヤチェーンにドライブチェーン用RSスプロケットは使用できるのでしょうか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A61 |

RSタイプの小形コンベヤ用アタッチ付チェーンであればドライブチェーン用RSスプロケットは使用可能です。 ただし、スプロケット径が小さな場合やアタッチメントが特殊な場合にはスプロケットとの干渉の考慮が必要ですのでご注意ください。 バイピッチにはバイピッチスプロケットを使用してください。 ただし、バイピッチSローラをご使用の場合で歯数が30歯以上ではRSスプロケットが使用可能となります。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q62 | バイピッチ(Sローラ)専用のバイピッチスプロケットにおいて奇数歯を推奨されているのはなぜですか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A62 |

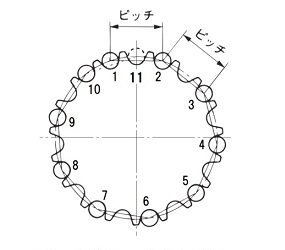

Sローラ用で割出歯数が奇数の場合は摩耗寿命が長くなりますので推奨しています。 バイピッチスプロケットは実際に噛合う歯数を作用歯数、見かけの歯数を割出歯数と呼びます。チェーンがSローラタイプの場合はチェーンが1歯とびに噛合います。(図1) Sローラ用で割出歯数が奇数の時には(図3)のように、1回転目のローラは番号1~10の順に1歯とびに噛合いますが、2回転目からは前周と異なる歯の番号11から噛合い始めます。ローラがスプロケットの回転毎に異なる歯と噛合うため、摩耗が少なく寿命が長くなります。 Rローラの場合は一歯ごとに噛合います。(図2) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q63 | ホローピンバイピッチを使用します。どんなスプロケットが使用できますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A63 |

標準RFバイピッチ使用時と同様に歯数30枚以上の場合はドライブチェーン用RSスプロケットが使用できます。 29歯以下の場合は使用できませんのでバイピッチスプロケットが必要です。 多列においてはRF2060以上のサイズは横ピッチが異なるため使用できません。この場合は特形チェーンに該当しますのでチェーン図をもとにスプロケットも特形で製作を検討いたします。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q64 | 小形コンベヤチェーンの取付精度と取付手順を教えてください。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A64 |

取付は水平度、平行度に注意して下記の要領で正しく行ってください。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q65 | 小形コンベヤチェーン用バイピッチスプロケットはどうなれば寿命ですか?点検のポイントを教えてください。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A65 |

図2 スプロケット歯の摩耗

図3 スプロケット歯の摩耗(側面) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q66 | 大形コンベヤチェーン用スプロケットの最小歯数はいくつでしょうか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A66 |

チェーンの掛かりを考慮し、6歯以上の歯数が必要です。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q67 | 大形コンベヤチェーン用スプロケットについて、ハブがついていないA形の製作は可能でしょうか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A67 |

可能ですが受注生産品となりますのでお見積をお願いします。 溶接されることを前提としている場合は材料によっては不具合につながることがあります。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q68 | 大形コンベヤチェーン用スプロケットには吊下げ用の穴はありますか? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A68 |

吊穴の設定があるものはカタログにて確認できます。 吊穴を設定しているものにはスプロケット本体寸法表に加え、吊穴寸法一覧表に吊穴寸法と吊穴の数を明記しています。 掲載されていない形番・歯数のスプロケットには吊下げ用の穴はありません。 ご要望の際は、製作検討のうえ都度見積りいたしますので、具体的な位置や大きさ、数をご指示ください。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q69 | 大形コンベヤチェーン用スプロケットの取付精度と取付手順を教えてください。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A69 |

取付は水平度、平行度に注意して下記の要領で正しく行ってください。

※取付精度は、コンベヤチェーン自体からみた一般的な値です。コンベヤ本体の精度上から制限がある場合には、それに準じてください。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Q70 | 大形コンベヤチェーン用スプロケットはどうなれば寿命ですか?点検のポイントを教えてください。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A70 |

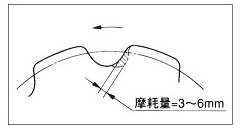

スプロケット歯面の摩耗限界は、図1を目安としてください。サイズ等により3~6mmが寿命です。 スプロケットの歯部が摩耗した状態でチェーンが噛み合うと、チェーンの摩耗が早くなるなど悪影響が出ます。歯部が摩耗している場合は取替えください。 スプロケットの歯の側面が摩耗している場合は、表1を参照し原因に対する処置を行ってください。 点検の工数削減や安全性向上にスプロケットの取替え時期が判るチェッカーズアイを搭載したスプロケットの製作が可能です。

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||