Q&A タイミングベルト・タイミングプーリ

お客様から寄せられました「よくある質問」をQ&A形式で掲載しています。質問をクリックして回答へお進みください。

タイミングベルト

Q&A内で語句を

| Q1 | タイミングベルトの取付時に張力を与える理由は? |

|---|---|

| Q2 | 取付張力の与え方は? |

| Q3 | 取付張力の確認方法は? |

| Q4 | 取付張力を測定する箇所は? |

| Q5 | 取付張力の最小値は? |

| Q6 | タイミングプーリのアライメント調整の必要性は? |

| Q7 | タイミングベルトの伸びとは? |

| Q8 | どのような状態になったときにタイミングベルトは寿命と判断するのか? |

| Q9 | タイミングベルトが切断する前に寿命を察知できるか? |

| Q10 | タイミングベルトが寿命に至る時間は? |

| Q11 | かみ合い歯数が6歯以上必要な理由は? |

| Q12 | 伝動能力表の着色部分の意味は? |

| Q13 | サーボモータを使用する場合の注意点は? |

| Q14 | カタログに記載がある標準幅以外のものは製作が可能か? |

| Q15 | 製作ができる最小幅は? |

| Q16 | カタログに記載されていないベルト長さのものは製作が可能か? |

| Q17 | 「ウルトラPXベルト耐油仕様」はあらゆる油種に対して効果があるか? |

| Q18 | 油周り・水周りの雰囲気で使用できるのか? |

| Q19 | タイミングベルトが使用可能な雰囲気温度は? |

| Q20 | 他社品との互換性はあるか? |

| Q21 | 使用前に注意しておくことは? |

| Q22 | タイミングベルトをタイミングプーリに取付けるときの注意点は? |

| Q23 | タイミングベルトの使用雰囲気で注意することは? |

| Q24 | タイミングベルトの保管で注意することは? |

| Q25 | 騒音の種類は? |

| Q26 | 騒音の対策は? |

| Q27 | RoHS指令に対応しているか? |

| Q28 | タイミングベルトの伝動効率はどのくらいか? |

| Q29 | タイミングベルトの早期切断 |

| Q30 | タイミングベルトの歯の摩耗 |

| Q31 | タイミングベルトの歯飛び |

| Q32 | タイミングベルトの歯のせん断破壊 |

| Q33 | タイミングベルト側面のムシレおよび摩耗 |

| Q34 | タイミングベルト歯面の縦列キズ |

| Q35 | タイミングベルトの部分的切断 |

| Q36 | タイミングベルトの膨潤 |

| Q37 | タイミングベルトの見かけ上の伸び |

| Q38 | タイミングベルト背面のゴムの粘りあるいは軟化 |

| Q39 | タイミングベルト背面ゴムの摩耗 |

| Q40 | タイミングベルト背面のゴムの亀裂 |

| Q41 | タイミングプーリの歯部の摩耗 |

テンションメータ

| Q42 | 測定可能範囲は? |

|---|---|

| Q43 | 購入する前に使ってみたいが、貸出はしているのか? |

| Q44 | 校正はしてもらえるのか? |

| Q45 | 校正適正期間は? |

ベルトクランプ

| Q46 | 材質は? |

|---|---|

| Q47 | カタログ記載品以外の特注品は製作可能か? |

| Q1 | タイミングベルトの取付時に張力を与える理由は? | ||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 |

タイミングベルト伝動では、力が作用するピッチセンターラインがタイミングプーリの歯先より外側にあるため、適切な張力を与えることで伝動が可能になります。 通常の伝動用途での取付張力はカタログ記載の推奨値を目安に設定していただくことが望ましいです。 また、位置決め精度を重視される用途の場合は、カタログ記載の最大値を上回らない範囲で高めに設定してください。 なお、負荷の状況や装置の都合により、推奨値を下回る取付張力を設定する場合は、振動や騒音が増大しないか、歯飛びなど伝動に不具合が生じていないかをご確認しながら設定してください。 取付張力が過度に高い場合や低い場合は、タイミングベルトの早期破損の原因になります。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q2 | 取付張力の与え方は? | ||||||||||||||||||||||||||||||||||

| A2 |

いずれかの軸を移動して調整する方法が望ましいですが、調整用のアイドラを設けるという方法もあります。 アイドラは、原則としてタイミングベルトのゆるみ側に設置して、調整後に固定できるようにしてください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q3 | 取付張力の確認方法は? | ||||||||||||||||||||||||||||||||||

| A3 |

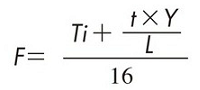

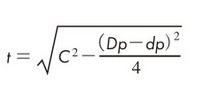

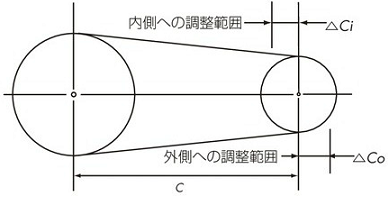

|

||||||||||||||||||||||||||||||||||

| Q4 | 取付張力を測定する箇所は? | ||||||||||||||||||||||||||||||||||

| A4 |

2軸(タイミングプーリが2個)の場合は、スパンの中央で測定してください。 多軸(タイミングプーリ・アイドラが3個以上)の場合は、スパンが一番長い箇所で測定してください。より安定した測定ができます。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q5 | 取付張力の最小値は? | ||||||||||||||||||||||||||||||||||

| A5 |

歯飛びをしない程度まで取付張力を下げることは可能です。歯飛びの発生は使用条件によって異なりますので、実機でご確認ください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q6 | タイミングプーリのアライメント調整の必要性は? | ||||||||||||||||||||||||||||||||||

| A6 |

タイミングベルトは、タイミングプーリのアライメントが正しい場合でもタイミングプーリの中央で走行せず、どちらかに片寄る性質があります。 その力は非常に弱いものですが、タイミングプーリのアライメントが悪いと、タイミングプーリの端に寄って走行し、ガイドフランジに強く押し付けられて損傷、切断する可能性があります。 また、ガイドフランジが脱落する可能性があります。 タイミングプーリのアライメントは下表の許容差内に調整してください。

■プーリ調整方法 図のように基準となるプーリにストレートエッジをあて、他のプーリをストレートエッジ全面に接触させること(ε=0とする)によりプーリを正しい位置に並べることができます。 また図のδを限度以下とすることにより軸の平行度を同時に出すことができます。 |

||||||||||||||||||||||||||||||||||

| Q7 | タイミングベルトの伸びとは? | ||||||||||||||||||||||||||||||||||

| A7 |

タイミングベルトで発生する伸びには2種類あります。

|

||||||||||||||||||||||||||||||||||

| Q8 | どのような状態になったときにタイミングベルトは寿命と判断するのか? | ||||||||||||||||||||||||||||||||||

| A8 |

適切に選定されたタイミングベルトでは歯布の摩耗が進行し、その後にベルト歯の欠落が発生します。 また、タイミングプーリの径が小さい場合や多軸レイアウトで屈曲が多い場合には、心線の屈曲疲労から切断に至ることもあります。 これらのように、タイミングベルトが正確にタイミングプーリとかみ合って伝動する機能が失われたときを寿命としています。 タイミングベルトは定期的に点検し、外観に傷などの異常や歯布の摩耗が認められた場合は、ベルト歯の欠落・タイミングベルトが切断する前に交換してください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q9 | タイミングベルトが切断する前に寿命を察知できるか? | ||||||||||||||||||||||||||||||||||

| A9 |

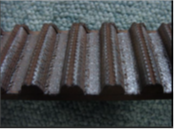

寿命は振動や騒音となって現れることがありますが、微妙なものもあり、事前に察知することは困難です。 タイミングベルトを定期的に点検して傷などの異常や歯布の摩耗が認められた場合は、ベルト歯の欠落や破断する前に交換してください。 つばきウルトラPX®ベルトは、歯布の摩耗がゴムの露出で確認しやすくなっていますので、交換の判断が容易にできるようになっています。 使用前

使用経過後

|

||||||||||||||||||||||||||||||||||

| Q10 | タイミングベルトが寿命に至る時間は? | ||||||||||||||||||||||||||||||||||

| A10 |

タイミングベルトは金属製ではないため疲労限度がなく、使用しているうちに疲労・摩耗が発生して、破損に至ります。 また、使用される条件・レイアウトによって耐久時間が大きく異なってくるため、寿命に至る時間を特定するのは大変困難です。 当社では材料の経年変化を考慮して最大でも5年での交換をお勧めしています。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q11 | かみ合い歯数が6歯以上必要な理由は? | ||||||||||||||||||||||||||||||||||

| A11 |

金属製のチェーンやギヤと異なりタイミングベルトの歯はナイロン織布で覆われたゴム材ですので、1歯だけでの伝動には適しておらず、複数歯で負荷を受ける必要があります。タイミングプーリとのかみ合い歯数が6歯未満だと1歯当たりの負荷が大きくなり歯欠けの原因になります。 かみ合い歯数が5歯もしくは4歯になってしまう場合は、カタログ記載の「かみ合い補正係数」を加えて選定してください。 駆動プーリの場合、かみ合い歯数が6歯以上でかみ合い角度が120度以上になるようご検討をお願いします。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q12 | カタログに記載されている伝動能力表の着色部分の意味は? | ||||||||||||||||||||||||||||||||||

| A12 |

この部分の組合せは小径プーリが高速で回転する条件になるため、タイミングベルト内部にある心線の屈曲疲労が促進されて寿命が短くなりますので使用を避けてください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q13 | サーボモータを使用する場合の注意点は? | ||||||||||||||||||||||||||||||||||

| A13 |

タイミングベルトの周速が速い場合、以下の現象が起こる可能性があります。

タイミングベルトを選定される際は、サーボモータの特性を考慮してトルクから検討することをお勧めしています。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q14 | カタログに記載がある標準幅以外のものは製作が可能か? | ||||||||||||||||||||||||||||||||||

| A14 |

製作可能なベルト幅もありますので、当社問合せ窓口もしくは取扱販売店へお問合せください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q15 | 製作ができる最小幅は? | ||||||||||||||||||||||||||||||||||

| A15 |

タイミングベルトの全高さの1.5倍が目安ですが品種によって異なりますので、当社問合せ窓口もしくは取扱販売店へお問合せください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q16 | カタログに記載されていないベルト長さのものは製作が可能か? | ||||||||||||||||||||||||||||||||||

| A16 |

エンドレスのタイミングベルトは金型を使って製作しますので、カタログに記載されていないベルト長さのものは製作ができません。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q17 | 「ウルトラPXベルト耐油仕様」はあらゆる油種に対して効果があるか? | ||||||||||||||||||||||||||||||||||

| A17 |

「ウルトラPXベルト耐油仕様」の耐油性は、一般的な潤滑油や切削油を使用した当社での各種試験結果に基づくものですので、すべての油種や使用条件等に対する耐性を保証しているものではありません。 個別の油種や使用条件に関する適用可否は、実機でご確認いただくかまたは当社までお問合せください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q18 | 油周り・水周りの雰囲気で使用できるのか? | ||||||||||||||||||||||||||||||||||

| A18 |

一般に、タイミングベルトに油や水が付着すると膨潤してタイミングプーリとかみ合わなくなり伝動能力の低下や早期破損の原因になります。特に油中や水中では使用できません。 当社では油や水がミスト状の環境下での耐久性を高めた「ウルトラPXベルト耐油仕様」「PXベルト耐水仕様」をラインアップしています。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q19 | タイミングベルトが使用可能な雰囲気温度は? | ||||||||||||||||||||||||||||||||||

| A19 |

-15℃~80℃の通常の環境下でご使用ください。一定の条件下で90℃まで使用可能なタイミングベルトもあります。 詳細は当社問合わせ窓口までお問合せください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q20 | 他社品との互換性はあるか? | ||||||||||||||||||||||||||||||||||

| A20 |

「PX歯形」は当社独自の歯形で他社との互換性はありませんので、つばきタイミングプーリとセットで使用してください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q21 | 使用前に注意しておくことは? | ||||||||||||||||||||||||||||||||||

| A21 |

注意点をまとめてカタログ「タイミングベルト伝動」に掲載しています。「取扱説明」のページをご使用前に必ずお読みください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q22 | タイミングベルトをタイミングプーリに取付けるときの注意点は? | ||||||||||||||||||||||||||||||||||

| A22 |

タイミングベルトは力を加えてもほとんど伸びません。 タイミングプーリに取付けるときはプーリ軸・アイドラ軸を移動させて取付けてください。 無理にタイミングプーリのガイドフランジを乗り越えさせようとするのは事故の原因になりますので避けてください。 アイドラを使用しない2軸伝動では、軸間距離調整しろを設けておいてください。 ■2軸伝動の軸間距離調整しろ

|

||||||||||||||||||||||||||||||||||

| Q23 | タイミングベルトの使用雰囲気で注意することは? | ||||||||||||||||||||||||||||||||||

| A23 |

清浄な雰囲気中で使用してください。 多量の水、油、溶剤がかかる恐れがある、埃が多い雰囲気中で使用される場合はカバーをしてタイミングベルト・プーリを保護してください。空気中に水分、油分が多い雰囲気では「ウルトラPXベルト耐油仕様」、水分が多い雰囲気では「PXベルト耐水仕様」が使用可能な場合がありますのでご検討ください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q24 | タイミングベルトの保管で注意することは? | ||||||||||||||||||||||||||||||||||

| A24 |

|

||||||||||||||||||||||||||||||||||

| Q25 | 騒音の種類は? | ||||||||||||||||||||||||||||||||||

| A25 |

一般的には次の通りです。

|

||||||||||||||||||||||||||||||||||

| Q26 | 騒音の対策は? | ||||||||||||||||||||||||||||||||||

| A26 |

|

||||||||||||||||||||||||||||||||||

| Q27 | RoHS指令に対応しているか? | ||||||||||||||||||||||||||||||||||

| A27 |

RoHS指令に対応しています。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q28 | タイミングベルトの伝動効率はどのくらいか? | ||||||||||||||||||||||||||||||||||

| A28 |

最大で98%程度です。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q29 | タイミングベルトの早期切断 | ||||||||||||||||||||||||||||||||||

| A29 |

[外観の特長] ベルト歯に対して平行に切断している。心線も短く揃って切断している。 [推定原因]

[対策]

■アイドラ選定時の最小プーリ歯数

注)3600r/minをこえる場合は基準伝動容量表を参照ください。

内側アイドラ

外側アイドラ |

||||||||||||||||||||||||||||||||||

| Q30 | タイミングベルトの歯の摩耗 | ||||||||||||||||||||||||||||||||||

| A30 |

[外観の特長]

[推定原因]

[対策]

|

||||||||||||||||||||||||||||||||||

| Q31 | タイミングベルトの歯飛び | ||||||||||||||||||||||||||||||||||

| A31 |

[推定原因]

[対策]

|

||||||||||||||||||||||||||||||||||

| Q32 | タイミングベルトの歯のせん断破壊 | ||||||||||||||||||||||||||||||||||

| A32 |

[外観の特長]

[推定原因] 「Q30タイミングベルトの歯の摩耗」「Q31タイミングベルトの歯飛び」の推定原因と同じ。これらの状況が続いた結果、せん断破壊に至る。 [対策] 「Q30タイミングベルトの歯の摩耗」「Q31タイミングベルトの歯飛び」の対策と同じですのでご参照ください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q33 | タイミングベルト側面のムシレおよび摩耗 | ||||||||||||||||||||||||||||||||||

| A33 |

[外観の特長]

[推定原因]

[対策]

|

||||||||||||||||||||||||||||||||||

| Q34 | タイミングベルト歯面の縦列キズ | ||||||||||||||||||||||||||||||||||

| A34 |

[外観の特長]

[推定原因]

[対策]

|

||||||||||||||||||||||||||||||||||

| Q35 | タイミングベルトの部分的切断 | ||||||||||||||||||||||||||||||||||

| A35 |

[外観の特長]

[推定原因]

[対策]

|

||||||||||||||||||||||||||||||||||

| Q36 | タイミングベルトの膨潤 | ||||||||||||||||||||||||||||||||||

| A36 |

[外観の特長]

[推定原因]

[対策]

|

||||||||||||||||||||||||||||||||||

| Q37 | タイミングベルトの見かけ上の伸び | ||||||||||||||||||||||||||||||||||

| A37 |

[推定原因] 軸の移動による軸同士の接近。 [対策] 軸を強固に固定してください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q38 | タイミングベルト背面のゴムの粘りあるいは軟化 | ||||||||||||||||||||||||||||||||||

| A38 |

[外観の特長]

[推定原因]

[対策]

|

||||||||||||||||||||||||||||||||||

| Q39 | タイミングベルト背面ゴムの摩耗 | ||||||||||||||||||||||||||||||||||

| A39 |

[外観の特長]

[推定原因]

[対策]

|

||||||||||||||||||||||||||||||||||

| Q40 | タイミングベルト背面のゴムの亀裂 | ||||||||||||||||||||||||||||||||||

| A40 |

[外観の特長]

[推定原因]

[対策]

|

||||||||||||||||||||||||||||||||||

| Q41 | タイミングプーリの歯部の摩耗 | ||||||||||||||||||||||||||||||||||

| A41 |

[外観の特長]

[推定原因]

[対策]

|

||||||||||||||||||||||||||||||||||

| Q42 | 測定可能範囲は? | ||||||||||||||||||||||||||||||||||

| A42 |

タイミングベルトの振動数でBDTM101は30~600Hz、BDTM201は10~5000Hzです。

|

||||||||||||||||||||||||||||||||||

| Q43 | 購入する前に使ってみたいが、貸出はしているのか? | ||||||||||||||||||||||||||||||||||

| A43 |

デモ機の貸出をおこなっています。詳細は当社問合せ窓口へお問合せください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q44 | 校正はしてもらえるのか? | ||||||||||||||||||||||||||||||||||

| A44 |

有償で承っています。当社商品取扱い販売店へご照会ください。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q45 | 校正適正期間は? | ||||||||||||||||||||||||||||||||||

| A45 |

校正周期はお客様の基準やご判断で設定をお願いします。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q46 | 材質は? | ||||||||||||||||||||||||||||||||||

| A46 |

高力アルミニウムに白アルマイト処理をしています。 質問へ戻る |

||||||||||||||||||||||||||||||||||

| Q47 | カタログ記載品以外の特注品は製作可能か? | ||||||||||||||||||||||||||||||||||

| A47 |

製作可能か検討しますので、当社商品取扱い販売店に図面を添えてご照会ください。 質問へ戻る |

||||||||||||||||||||||||||||||||||