製品情報 トップチェーン用アクセサリ

専用スプロケット、アイドラ、プラレール、セットカラー、チェーンガイドパーツ、フレームサポートパーツ、プロダクトガイドパーツ、ベアリングユニットなどのコンベヤ周辺部品を多数ラインアップしています。

各アクセサリの使用方法などは下記画像をクリックし、ご確認ください。

- スプロケット

- 分解・連結工具

ステンレストップチェーン用アクセサリ一覧

チェーン形番の適用アクセサリを

アクセサリ形番を

※形番クリックで詳細情報を表示します。寸法図はクリックで拡大します。

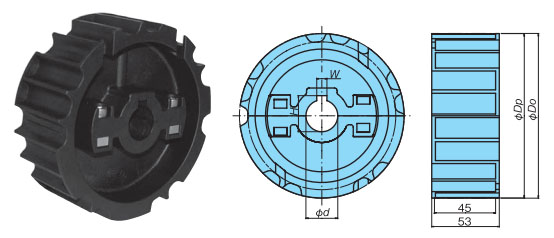

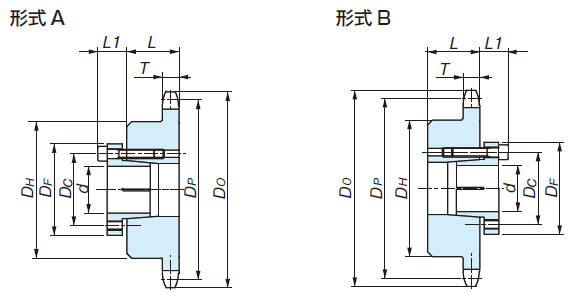

スプロケット

( クリックで一覧表を クリックで一覧表を表示します。) |

適用チェーン形式 | 適用チェーン ピッチ mm |

歯数 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

TT

|

TT | 38.10 | 19, 21, 23, 25 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

× (ドラッグで移動できます)

× (ドラッグで移動できます)

× (ドラッグで移動できます)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

TTU

|

TTU | 38.10 | 21, 23, 25 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

× (ドラッグで移動できます)

× (ドラッグで移動できます)

× (ドラッグで移動できます)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

TS/TSA

|

TS, TSA, TSA-HTP, TS-CTP | 38.10 | 9½, 10½, 11½, 12, 12½ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

TO

|

TO, TORP/TOSP | 76.20 | 11, 31 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

TU

|

TU | 76.20 | 11 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

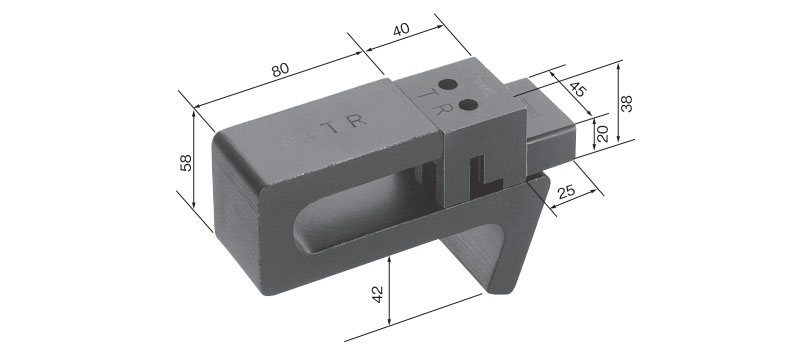

分解・連結工具

| アクセサリ名称 (  クリックで一覧表を クリックで一覧表を表示します。) |

適用チェーン形番 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

分解・連結工具

|

TT, TRU, TTKU, TS | ||||||||||||

|

|

|||||||||||||