ピンギヤドライブユニット®

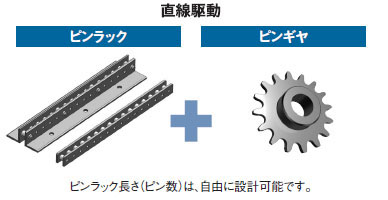

- 回転駆動、直線駆動にコストダウンを提案

- ピンギヤドライブユニット®は、ギヤ・ラックなどに代わる新しい駆動ユニットです。

- ピン機構のホイール・ラックと、特殊歯形ギヤの組合せにより回転・直線駆動部の設計自由度が大きく拡がります。

- *据付が簡単:分割セグメント方式を採用し、据付作業が簡単に行えます。また。ラフな据付精度でもご使用いただけます。

- *大きな伝達トルク:ピンギヤは余裕あるモジュールで設計、ピンホイール・ラックとのバランスの良さから大きな伝達トルクを発揮します。

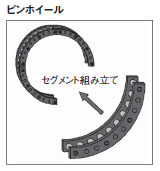

- *大形装置への使用が可能:ホイールタイプはセグメント数を増やすことで、大形駆動装置への採用が可能となります。

- *鉄鋼業界などの大形装置に最適なサイズをラインアップ:大形ギヤを凌駕するコストと接線力を実現します。

カタログ・取扱説明書

構成

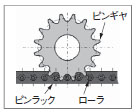

ピンギヤドライブユニットは、ピンギヤと噛み合うピンラック(又はピンホイール)がセットになったドライブユニットです。

特長

取り付けが簡単、ラフな据え付けを許容します。

- ・ピンラック・ピンホイールには、全てのピン部に取付用の中空ピン(ホローピン)を使用しておりますので、この穴を利用して簡単に取付作業ができます。

セグメント化ユニットの組み合わせで大型機に対応できます。

- ・ラックの場合は、継ぎ面を合わせる事でユニットのピッチ間隔を保ち継ぐ事ができ、長い直線駆動が可能になります。

- ・大型機用のピンホイールはセグメント組み立てになっていますので、セグメントの組み合わせで大直径のピンホイール対応ができます。

チェーン方式と比べて伝達力が大きくサイズダウンが図れます。

構造

ピンギヤは特殊歯形を持ち、ローラと連続的にスムーズに噛み合います。

歯部は強度向上・摩耗強度向上のため、硬化処理されています。

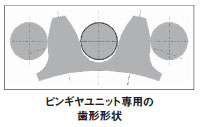

ピンギヤ専用歯形

ピンギヤの歯形は、ピンラック・ピンホイールとスムーズな噛合い伝動ができる近似インボリュート曲線の形状をベースに、さらなる強度向上のために当社独自の歯形形状を採用しています。

形番表示例 (直線駆動の場合)

ピンラック

| PDU050 | - | S | P | A | 080P | - | R |

| | 枠番 |

| | |

| ピンラック |

| | |

| 全ピン数 |

| 仕様 無記号:スチールタイプ標準仕様 K:スチールタイプ無電解ニッケルめっき仕様 R:スチールタイプ高防錆仕様 Y:フレキシブルタイプ S:ステンレスタイプ標準仕様 |

||

|

| 駆動方式 S:直線駆動 |

| 取付方式 F:フラット形 A:アングル形 |

||||||

ピンギヤ

| PDU050 | - | S | G | B | 014T | - | R |

| | 枠番 |

| | |

| ピンギヤ |

| | |

| 歯数 |

| 仕様 無記号:スチールタイプ標準仕様 K:スチールタイプ無電解ニッケルめっき仕様 R:スチールタイプ高防錆仕様 Y:フレキシブルタイプ S:ステンレスタイプ標準仕様 |

||

|

| 駆動方式 S:直線駆動 |

| ピンギヤ形式 B:片ハブ形 C:両ハブ形 |

||||||

形番表示例 (回転駆動の場合)

ピンホイール

・全周の場合

| PDU070 | - | G | P | F | 300P | - | R |

| | 枠番 |

| | |

| ピンホイール |

| | |

| 全ピン数 |

| 仕様 無記号:スチールタイプ標準仕様 K:スチールタイプ無電解ニッケルめっき仕様 R:スチールタイプ高防錆仕様 Y:フレキシブルタイプ S:ステンレスタイプ標準仕様 |

||

|

| 駆動方式 G:外接回転駆動 N:内接回転駆動 |

| 取付方式 F:フラット形 |

||||||

・円周の一部分(360°未満)のみの場合

| PDU070 | - | G | P | F | 300P | 090P | - | R |

| | 枠番 |

| | |

| ピンホイール |

| | |

| 全ピン数 |

| 必要ピン数 |

| 仕様 無記号:スチールタイプ標準仕様 K:スチールタイプ無電解ニッケルめっき仕様 R:スチールタイプ高防錆仕様 Y:フレキシブルタイプ S:ステンレスタイプ標準仕様 |

||

|

| 駆動方式 G:外接回転駆動 N:内接回転駆動 |

| 取付方式 F:フラット形 |

|||||||

ピンギヤ

| PDU070 | - | G | G | C | 017T | 300P | - | R |

| | 枠番 |

| | |

| ピンギヤ |

| | |

| 歯数 |

| ピンホイール全ピン数 |

| 仕様 無記号:スチールタイプ標準仕様 K:スチールタイプ無電解ニッケルめっき仕様 R:スチールタイプ高防錆仕様 Y:フレキシブルタイプ S:ステンレスタイプ標準仕様 |

||

|

| 駆動方式 G:外接回転駆動 N:内接回転駆動 |

| ピンギヤ形式 B:片ハブ形 C:両ハブ形 |

|||||||

仕様

タイプ・仕様別対応枠番

ピンギヤドライブユニットは各タイプや仕様によって適用枠番が異なるため、選択の際はご注意ください。

| 品種 | 枠番 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PDU020 | PDU022 | PDU030 | PDU035 | PDU040 | PDU050 | PDU055 | PDU070 | PDU080 | PDU090 | PDU120 | PDU150 | PDU180 | PDU240 | |||

| スチール タイプ |

標準仕様 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| 無電解 ニッケルめっき仕様 |

○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | - | - | - | ||

| 高防錆仕様 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○※ | ○※ | - | - | - | - | ||

| フレキシブルタイプ | - | - | - | - | - | ○ | ○ | ○ | ○ | ○ | - | - | - | - | ||

| ステンレスタイプ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | ||

※PDU080以上の枠番でアングル形は対応していません。

標準仕様一覧

スチールタイプとフレキシブルタイプとステンレスタイプの3種類あります。使用環境に合わせてご選択ください。

| 枠番 | ピッチ mm |

許容接線荷重 kN | ||

|---|---|---|---|---|

| スチールタイプ | フレキシブルタイプ | ステンレスタイプ | ||

| PDU020 | 20 | 4.7 | - | 0.8 |

| PDU022 | 22 | 7.7 | - | 1.1 |

| PDU030 | 30 | 12.8 | - | 1.9 |

| PDU035 | 35 | 19.5 | - | 2.6 |

| PDU040 | 40 | 27.3 | - | 4.1 |

| PDU050 | 50 | 31.7 | 25.3 | 5.1 |

| PDU055 | 55 | 52.9 | 37.0 | 7.0 |

| PDU070 | 70 | 60.7 | 48.5 | 9.9 |

| PDU080 | 80 | 71.5 | 57.2 | 12.0 |

| PDU090 | 90 | 98.9 | 79.1 | 16.8 |

| PDU120 | 120 | 122.5 | - | - |

| PDU150 | 150 | 240 | - | - |

| PDU180 | 180 | 347 | - | - |

| PDU240 | 240 | 525 | - | - |

| スチールタイプ・フレキシブルタイプ | ステンレスタイプ | ||

|---|---|---|---|

| 最高使用速度 | 接線速度:50m/min | ||

| 使用雰囲気 | 屋内(雨や水のかからない場所) | 腐食雰囲気 | |

| 使用温度 | ‐10℃~150℃ | ‐20℃~400℃ | |

| 材質 | フレーム | 圧延鋼 | オーステナイト系ステンレス鋼 |

| ブシュ | 合金鋼 | 析出硬化系ステンレス鋼 | |

| ローラ | 合金鋼 | オーステナイト系ステンレス鋼 | |

| ピンギヤ | 炭素鋼(歯先硬化仕様) | オーステナイト系ステンレス鋼 | |

| 枠番 | バックラッシ mm | 中心間距離精度 mm | ||||

|---|---|---|---|---|---|---|

| スチールタイプ | フレキシブルタイプ | ステンレスタイプ | スチールタイプ | フレキシブルタイプ | ステンレスタイプ | |

| PDU020 | 0.26 ~ 0.47 | - | 0.26 ~ 0.47 | ±0.25 | - | ±0.25 |

| PDU022 | 0.32 ~ 0.57 | - | 0.32 ~ 0.57 | ±0.3 | - | ±0.3 |

| PDU030 | 0.32 ~ 0.66 | - | 0.32 ~ 0.67 | ±0.4 | - | ±0.4 |

| PDU035 | 0.33 ~ 0.88 | - | 0.33 ~ 0.88 | ±0.5 | - | ±0.5 |

| PDU040 | 0.41 ~ 0.86 | - | 0.41 ~ 0.86 | ±0.6 | - | ±0.6 |

| PDU050 | 0.53 ~ 0.98 | 0.77 ~ 1.22 | 0.53 ~ 1.08 | ±0.7 | ±1.57 | ±0.7 |

| PDU055 | 0.61 ~ 1.06 | 1.01 ~ 1.46 | 0.61 ~ 1.26 | ±0.75 | ±1.72 | ±0.75 |

| PDU070 | 0.86 ~ 1.24 | 1.36 ~ 1.74 | 0.86 ~ 1.61 | ±0.9 | ±2.02 | ±0.9 |

| PDU080 | 0.89 ~ 1.20 | 1.49 ~ 1.80 | 0.89 ~ 1.74 | ±1 | ±2.2 | ±1 |

| PDU090 | 0.97 ~ 1.42 | 1.57 ~ 2.02 | 0.97 ~ 1.92 | ±1.2 | ±2.7 | ±1.2 |

| PDU120 | 1.30 ~ 1.57 | - | - | ±1.6 | - | - |

| PDU150 | 1.63 ~ 1.96 | - | - | ±2 | - | - |

| PDU180 | 1.95 ~ 2.36 | - | - | ±2.4 | - | - |

| PDU240 | 2.60 ~ 3.14 | - | - | ±3.2 | - | - |

無電解ニッケルめっき仕様

無電解ニッケルめっきにより、優れた耐摩耗性と耐食性を実現した仕様をラインアップ。

この仕様は、均一な表面処理により効果的にコ-ティングされます。

・用途例:運搬機械や工作機など

・標準シリーズと許容接線荷重は変わりませんので、標準シリーズと同サイズでの選定が可能です。

・受注生産品です。

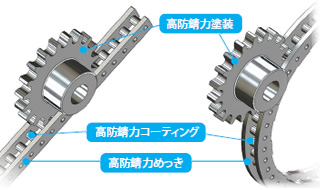

高防錆仕様

特殊表面処理により耐食性をアップした高防錆仕様をラインアップ。

パーツ毎に適切な防錆処理を施していますので、屋外・水辺・海岸地域など厳しい腐食環境で強い防錆力を発揮します。

・用途例:立体駐車場、大形搬送台車、鋳造ライン、水門など

・標準シリーズと許容接線荷重は変わりませんので、標準シリーズと同サイズでの選定が可能です。

・受注生産品です。

フレキシブルタイプ

従来よりも中心間距離公差を拡大し、ピンラック/ピンホイールとピンギヤ間の隙間を広げたフレキシブルタイプをラインアップ。

据付精度が厳しい装置だけでなく、熱膨張などで運転中に据付位置が変わる際に効果的です。

・用途例:キルンドライヤや土木機械

・標準シリーズよりも許容接線荷重が下がります、選定時はリーフレットを参照ください。

・受注生産品です。

特殊バックラッシ仕様 (標準の許容接線荷重とは異なります)

・大バックラッシ仕様

バックラッシを大きくすることで容易な据付が可能です。

・小バックラッシ仕様

バックラッシを小さくすることが可能です。(標準バックラッシの2/3 対応枠番:PDU020~PDU120)

潤滑

運転前には、全てのローラ外周面に極圧系グリースを塗付してください。ピンホイールあるいはピンラックのローラ内面には、あらかじめ潤滑用のグリースを塗付しています。

水中使用など潤滑用グリースが使用できない雰囲気、130℃以上の高温雰囲気でご使用になる場合は、別途ご相談ください。

取付方法

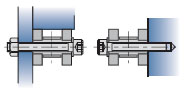

ピンホイール、ピンラックフラット形

中空ピンを使用していますので、この穴を利用して側面を相手装置にボルトで固定できます。

取付に際して凸部のある面にストッパまたはガイドを設けて位置決めができます。

ピンラックアングル形

アングル形の直線ラックは、ボルト締結用の穴を用いて脚面を相手装置に固定できます。

詳細情報

ピンホイール・ピンラック・ピンギヤの詳細情報は下記リンク先をご参照ください。