製品情報 プラブロックチェーン用アクセサリ

専用スプロケット、アイドラ、プラレール、セットカラー、チェーンガイドパーツ、フレームサポートパーツ、プロダクトガイドパーツ、ベアリングユニットなどのコンベヤ周辺部品を多数ラインアップしています。

各アクセサリの使用方法などは下記画像をクリックし、ご確認ください。

- プラレール

- リターンローラ

- 高回転性リターンローラ

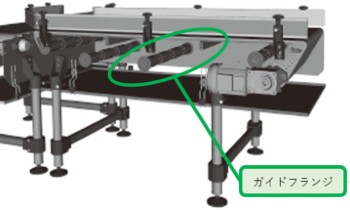

- ガイドフランジ

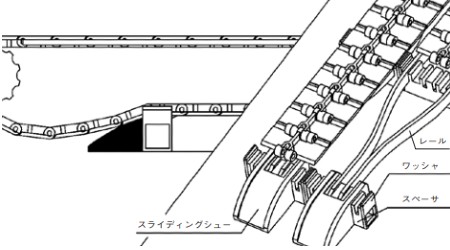

- スライディングシュー

- スペーサ

- ワッシャ

- 専用レール

- モジュールトランスファ

ローラプレート

×

(ドラッグで移動できます)

×

(ドラッグで移動できます)

×

(ドラッグで移動できます)

×

(ドラッグで移動できます)

×

(ドラッグで移動できます)

×

(ドラッグで移動できます)

×

(ドラッグで移動できます)

×

(ドラッグで移動できます)