ジップチェーンリフタ®

- ジップチェーン機構を採用したシザーリフタ

- 今までにない高速昇降を実現した画期的なリフタです。

- ジップチェーンリフタは、ジップチェーンでダイレクトに天板を押し上げるテーブル式リフタです。

- 油圧式に比べ、3~10倍の高速昇降が可能。高頻度運転にも対応しており、最大50%の省エネ効果を発揮します。

ジップチェーンとは?

- 高速・高頻度運転

- 多点停止機能

- ダントツの省スペース

ジップチェーンとは、2本のチェーンがジッパーのように噛み合い、1本の強固な柱状になり「押し・引き」ができる当社独自開発のチェーンです。

つばきジップチェーンアクチュエータは、このチェーンを使った直線作動機として製品化したものです。

従来の空圧・油圧シリンダに比べ、省スペース、高速・高頻度運転、多点停止機能、高停止精度、取付方向自由など、環境配慮点を含め多くの特徴を有し、小形アクチュエータから大形リフタまで幅広く使用されています。

動画コンテンツ

ジップチェーンとスプロケットの噛合い

ジップチェーンによる天板押上げ

1,000kg タイプ

500kg 7m テレスコタイプ

特長

他機構との比較

| 速度 | 高頻度 | 停止精度 | 期待寿命 | |

|---|---|---|---|---|

| ジップチェーンリフタ | ◎ | ◎ | ◎ | ◎ |

| 電動ネジ式リフタ | × | × | ○ | × |

| 油圧式リフタ | × | × | × | × |

つばき独自のチェーン技術が可能にした優れた性能

高速油圧式の2.5倍

最大昇降速度100m/minの高速運転を実現。

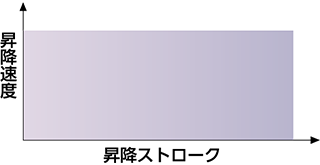

安定した速度で天板を直接押し上げる機構のため、モータの回転速度に比例し、一定の速度で昇降が可能です。複数台の同期運転も可能です。

ジップチェーンリフタ

全ストローク域で速度が安定

油圧式リフタ

油圧シリンダが斜め方向に伸縮し、天板を昇降させるため、速度が変化してしまいます。

高頻度油圧式の4.5倍

ジップチェーンリフタは、油圧式のように高頻度になるほど

油圧ユニットのタンク容量を大きくする必要がありません。

また油圧式や他方式では実現できない1分間に1往復以上、

かつ多点停止を伴うような連続運転も可能です。

停止精度油圧式は中間停止困難

ジップチェーンリフタは、制御構成が簡単なため、多点停止・多段位置決めが容易に実現できます。

期待寿命油圧式の10倍以上

ジップチェーンリフタは、天板を直接押し上げる機構のため、ヒンジやローラ部に加わる負荷が小さく、100万往復以上の長寿命を実現できます。

仕様

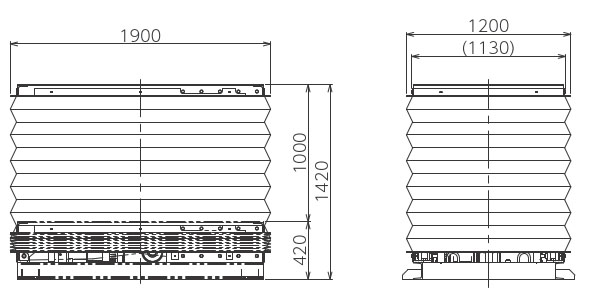

- ・許容積載質量:1,000kg/50kg

- ・ストローク:1,000mm/1,600mm/300mm/500mm

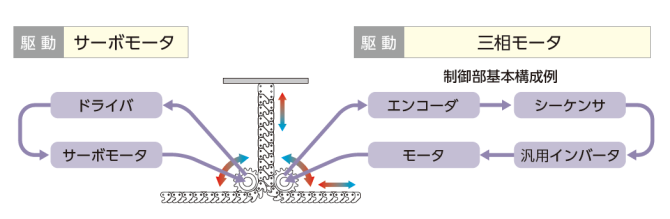

- ・駆動部:三相モータ付/サーボモータ付

- ・パンタ段数:1段/2段

カタログ・取扱説明書

形番表示

| ZSL | 1000 | L | 10 | G | 1 | - | T6 |

| | | ジップチェーンリフタ |

| 許容積載質量 1000:1000kg 0050:50kg |

| 速度 S:~6m/min L:6~12m/min M:12~m/min |

| ストローク 10:1000mm 16:1600mm 03:300mm 05:500mm |

| 駆動部 G:三相モータ付 K:サーボモータ付 |

| パンタ段数 1:1段 2:2段 |

| オプション 詳細は下記参照 |

|

製品形番ナビ

許容積載質量

積載物の許容質量です。

速度

昇降速度を表す記号です。

各機種の速度値は詳細情報をご参照ください。

ストローク

昇降できる距離です。

駆動部

G:三相モータ付きです。

K:サーボモータ付きです。

パンタ段数

1:1段パンタタイプです。

2:2段パンタタイプです。

オプション記号

J:開口部にジャバラを取り付ける仕様です。

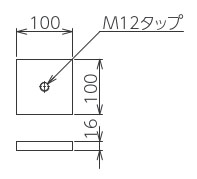

T6、T8:テーブル上面に固定用の座とタップ穴を設けます。

(T6:タップ6カ所、T8:タップ8カ所)

V:電源の電圧が倍電圧となります。

E:モータ後部にロータリーエンコーダを装着します。

製品形番一覧【標準仕様】

※形番クリックで詳細情報を表示します。

| 許容積載質量 kg |

ストローク mm |

駆動部 | 速度 | ||

|---|---|---|---|---|---|

| 12~m/min | 6~12m/min | ~6m/min | |||

| 1000 | 1000 | G(三相モータ付) | --- | ZSL1000L10G1 | ZSL1000S10G1 |

| 1600 | --- | ZSL1000L16G2 | ZSL1000S16G2 | ||

| 50 | 300 | --- | --- | ZSL0050S03G1 | |

| 500 | --- | --- | ZSL0050S05G2 | ||

| 1000 | 1000 | K(サーボモータ付) | ZSL1000M10K1 | --- | --- |

| 1600 | ZSL1000M16K2 | --- | --- | ||

| 50 | 300 | ZSL0050M03K1 | --- | --- | |

| 500 | ZSL0050M05K2 | --- | --- | ||

オプション

全周ジャバラ[オプション記号:J]

・ジップチェーンリフタ本体への挟み込みを抑制する、全周タイプのジャバラです。

※分割タイプも特形で対応可能ですので、ご相談ください。

| ストローク 1000mm 概略質量:35kg | ストローク 1600mm 概略質量:40kg |

|---|---|

タップ座[オプション記号:T6, T8]

・テーブル上面に固定用の座とタップ穴を設けます。

| タップ6カ所:T6 | タップ8カ所:T8 | タップ部詳細図:T8 |

|---|---|---|

|

モータ電圧400V級[オプション記号:V]

・駆動用のモータの電圧を400V級に変更します。

対応サイズ:ZSL1000□□□G、ZSL1000M□□K、ZSL0050S□□G

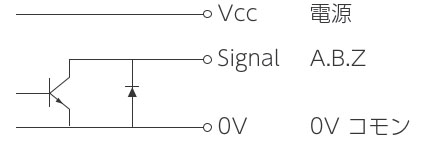

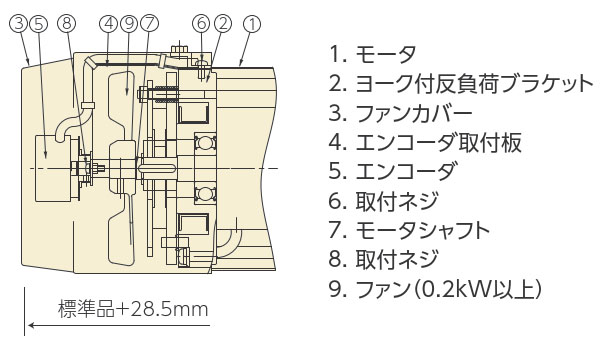

ロータリエンコーダ付[オプション記号:E]

・三相モータ付のモータ反負荷側軸端にロータリエンコーダを組込み、モータの回転信号が出力できるようになります。

対応サイズ:ZSL1000□□□G□

特長

・制御性

減速機よりオープンコレクタ出力信号が取出せますので、さまざまな運転が可能になります。

・コンパクト

モータ軸とロータリエンコーダをカップリングで接続する必要がありません。

・コストダウン

従来の別置きと比べ、カップリング・ベースプレートやレベル合わせ作業が不要です。

ロータリエンコーダ部仕様

別売りオプション

メンテナンスバー

・保守・点検時に、止むを得ず天板フレーム下の空間に身体または身体の一部を入れなければならない場合、

安全対策として必ずメンテナンスバーをご使用ください。

・ZSL0050シリーズにはメンテナンスバーが付属していますが、ZSL1000シリーズには付属していません。

ZSL1000シリーズをお求めの場合は、オプション品ZSL1000用メンテナンスバーを併せてお求めください。

・メンテナンスバーはストローク1000mmでの使用を標準としています。異なるストロークで使用される場合はご相談ください。

| 形番 | 適用機種 | 標準価格 | 納期 |

|---|---|---|---|

| ZSL1000MB10 | ZSL1000~ | お問合せください | お問合せください |

選定

ご使用条件・ご希望条件に該当するリフタを担当者が選定します。

本ページ上部の「選定計算」のタブをクリックしてください。

特殊仕様品

400kg 2段パンタタイプ

モータ外置き仕様:

ジップチェーン2本突き

2,000kg 1段パンタタイプ

モータ外置き仕様:

ジップチェーン4本突き

300kg 3段テレスコタイプ

モータ外置き仕様:

ジップチェーン2本突き

650kg ポストタイプ

モータ外置き仕様:

ジップチェーン2本突き