製品情報 直動機器

つばきの直動機器は、高品質な自社製ネジを使用している電動式のシリンダとジャッキ、当社独自のジップチェーン駆動のジップチェーンアクチュエータをラインアップしています。

ネジ機構とジップチェーン機構のいずれも、製品の持つ特長を最大限に活かし、高速・高頻度の運転や高い精度が求められる運転など、幅広い用途でご使用いただけます。

※ジップチェーン機構とは、2本のチェーンがジッパーのように噛み合うことで、1本の強固な柱状となり「押し・引き」で使用できる当社独自の技術です。

直動機構の種類

ジップチェーン機構

- 高速

- 高頻度

- 高耐久性

- コンパクト

つばきの独自技術「ジップチェーン」を用いた機構です。

コンパクト性に優れ、高タクト運転に求められる高速・高頻度・耐久性を持っています。

2本のチェーンを噛合せ1本の棒状にすることで、押し引きを可能にしました。

ジッパーのように噛合う様子からジップチェーンと名づけました。

(ジップチェーン機構の特設サイトはこちら)

ボールネジ機構・台形ネジ機構

- 高頻度

- 大許容荷重

- 静粛性

ボールネジ機構

ネジ軸とナットの間に鋼球を入れ、転がり摩擦することで、高効率で動作できるようにした機構です。

台形ネジ機構に比べて高速・高頻度用途に適しているので、生産性が求められる組立ラインなどに適しています。

また、高効率なので駆動源を小形化することができます。

信頼性の高い内製のボールネジを使用しているため、走行寿命の予測も可能です。

ボールネジ1回転当たりの進む距離(リード)が通常のボールネジより長いものをハイリードボールネジと呼び、通常のボールネジと同じ入力回転速度でも高速化が実現できます。

台形ネジ機構

ネジ軸とナットが滑り摩擦することで動作する機構で、メンテナンス用途などの低速・低頻度での運転に向いています。

ボールネジ機構にはないセルフロック性を有しているので、荷重保持が可能です。

また、構造がシンプルなため経済的です。

つばきの直動機器製品群

| 電動シリンダ:パワーシリンダ | スクリュージャッキ: リニパワージャッキ |

ボールネジ昇降ユニット: リニスピードジャッキ |

噛合チェーン式アクチュエータ: ジップチェーンアクチュエータ |

||

|---|---|---|---|---|---|

|

|

|

|

||

| 機構の種類 | ボールネジ 台形ネジ |

ボールネジ ハイリード ボールネジ |

台形ネジ | ボールネジ | ジップチェーン |

| 目的 | 負荷の押し引き | 負荷の押し引き | 負荷の保持 | 負荷の押し引き | 負荷の押し引き |

| 特長 | モータ一体型で簡単配線 クリーンな環境を実現 |

各種ねじタイプを選択可 | 高速・高頻度、低床、長寿命 | 他機構を圧倒する高速・高頻度、 低床、長寿命 |

|

| 推力 | 最大490kN | 4.90kN~980kN | 1.96kN~980kN | 15kN~50kN | 400N~2000N |

| ストローク | 最大2000mm | 最大2000mm | 最大1500mm | 最大2000mm | |

| 速度・運転頻度 | 最大速度:333mm/s 負荷時間率:50%ED※1 |

ネジ軸最大速度: 50~120mm/s※2 許容負荷時間率: 30%ED |

ネジ軸最大速度: 40mm/s 許容負荷時間率: 20%ED |

ネジ軸最大速度:200mm/s 許容負荷時間率:100%ED※3 |

最大速度:1000mm 負荷時間率:100%ED |

| 用途例 |

傾動装置

ストッパ |

テーブル昇降

圧延ロール |

トラバーサの

取出し |

段積・段ばらし

パレットの |

|

- ※1 エコシリーズ サーボタイプの場合

- ※2 ネジタイプによって異なります

- ※3 条件により異なります

直動機器製品一覧

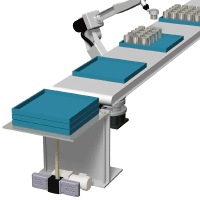

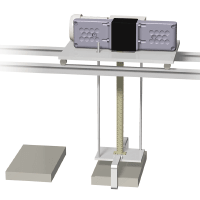

高速・高頻度運転、低床化を実現した革新的な駆動用ユニット

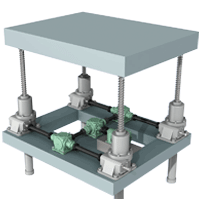

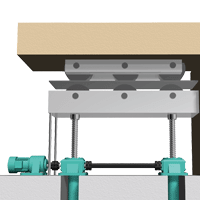

リニスピードジャッキは、サーボモータ駆動に最適化された革新的なボールネジユニットです。

通常、ボールネジを用いた昇降機構は減速機・ボールネジなどの関連部品をそれぞれ手配し組み付ける必要がありました。

リニスピードジャッキなら、それらをユニット化しているので、選定・据付の手間が大幅に省けます。

また、油圧・空圧シリンダからの置換実績も多数ございます。

リニスピードジャッキ®

形番 SJ~

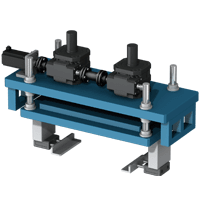

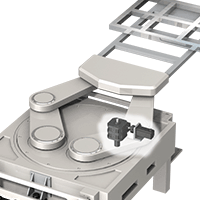

サーボモータの性能を最大限に活用できるボールネジ昇降ユニット

- ・選定・据付の工数削減:

ボールネジと減速部がコンパクトにユニット化されているので、構成部品が少なく選定・設計の手間が省けます。オプションのサーボモータ用フランジを使用すればサーボモータ用カップリングも不要です。また、構成部品が少ないので、調整の必要な個所が少なく据付が容易です。 - ・超高速化:

サイズを大きくしなくても、200㎜/sの高速領域で大荷重を搬送できる「定推力」を実現しました。 - ・高頻度運転対応:

最大100%EDの高頻度運転が可能となりました。

(※%ED:一定の運転サイクル内での運転時間の割合。よって100%ED=連続運転可能) - ・低床・コンパクト化:

ボールナットをギヤケースに内蔵することで低床化を実現しました。 - ・長寿命:

高機能ボールネジにより、従来よりもはるかに長い走行寿命を達成しました。

許容推力 kN

15, 30, 50

ネジの種類

特殊ボールネジ

ストロークmm

100~1500

複数台連動による昇降機構の構築に必要なカップリング・ギヤボックスなどの一括選定が可能です。