Q&A 直動機器

お客様から寄せられました「よくある質問」をQ&A形式で掲載しています。質問をクリックして回答へお進みください。

リニスピードジャッキ

Q&A内で語句を

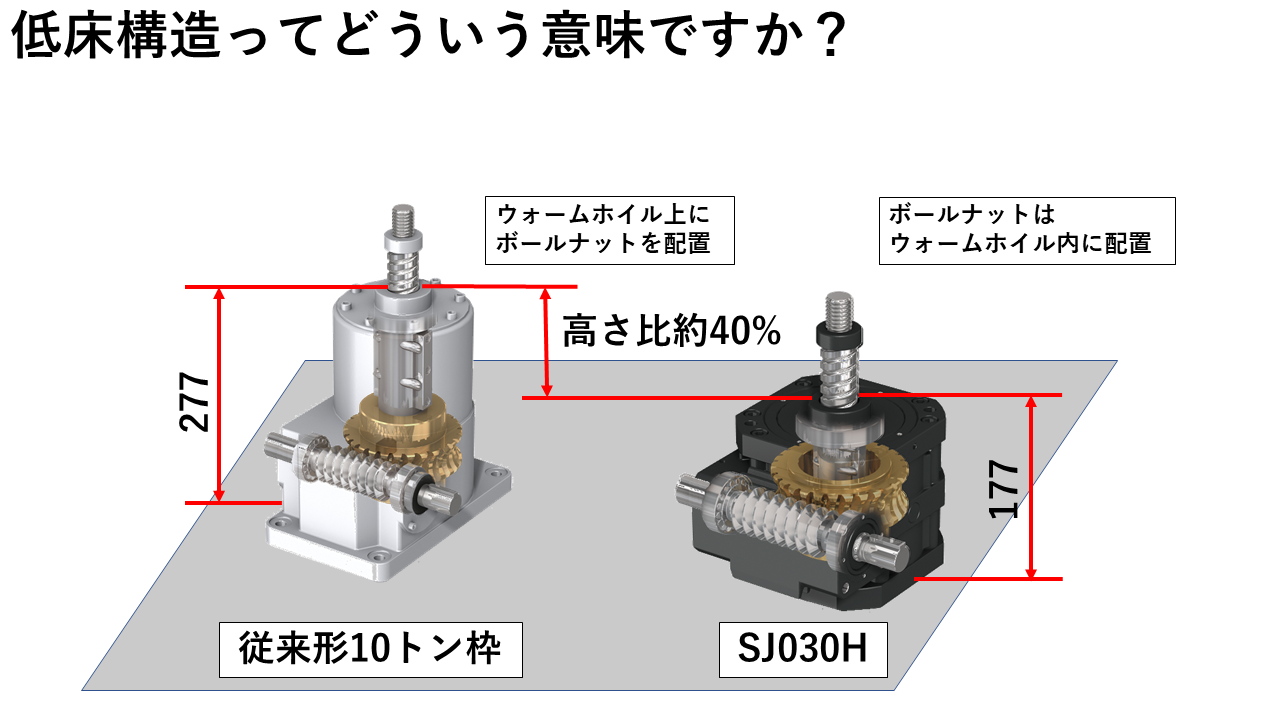

| Q1 | 低床構造ってどういう意味ですか? |

|---|---|

| A1 | 従来形ウォームジャッキはウォームホイルの上部にボールナットを乗せた構造になっています。 |

| Q2 | 200mm/sは、一般的なウォームジャッキよりも速いのですか? |

| A2 | 従来形ウォームジャッキでは枠番にもよりますが、最高速度は125mm/s程度です。 |

| Q3 | どうやって、高速運転が可能になるのですか? |

| A3 | リニスピードジャッキでは、従来形よりもウォームの芯間を大きくしています。 |

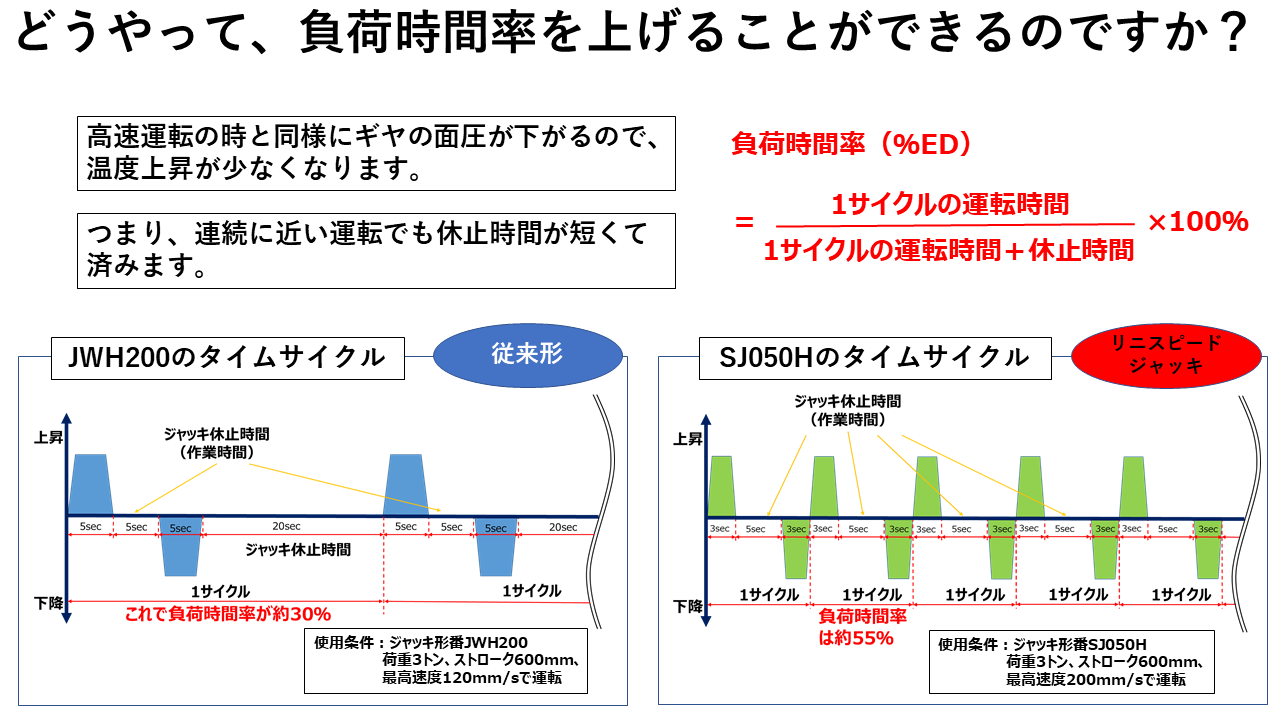

| Q4 | どうやって、負荷時間率を上げることができるのですか? |

| A4 | 前項と同じ理由で、発熱が抑えられるので、5トン枠同士であれば、発熱が少ない分、リニスピードジャッキの方が休止時間が少なくて済みます。これにより負荷時間率が従来形より上がるのです。 |

| Q5 | どうして長寿命になるのですか? |

| A5 | 一般的なウォームジャッキに使われているボールネジよりも高機能ネジを使用しています。 |

| Q6 | 高機能ネジってどういうネジですか? |

| A6 | 企業機密の為、内容について申し上げられませんが、一般的なボールネジから材質等を見直し、同じ枠番サイズであれば、従来のジャッキに対し10倍以上の期待走行距離を有しています。 |

| Q7 | 従来形ウォームジャッキは推力制限がありますか? |

| A7 | ウォームギヤは入力回転速度が上がると出力軸許容トルクが低下します。 |

| Q8 | どうしてリニスピードジャッキの無負荷空転トルクは大きいのですか? |

| A8 | 一つは、従来形に比べ、ウォーム芯間が大きくなっています。この為、潤滑油の撹拌抵抗やオイルシールの摺動抵抗が大きくなるのです。 |

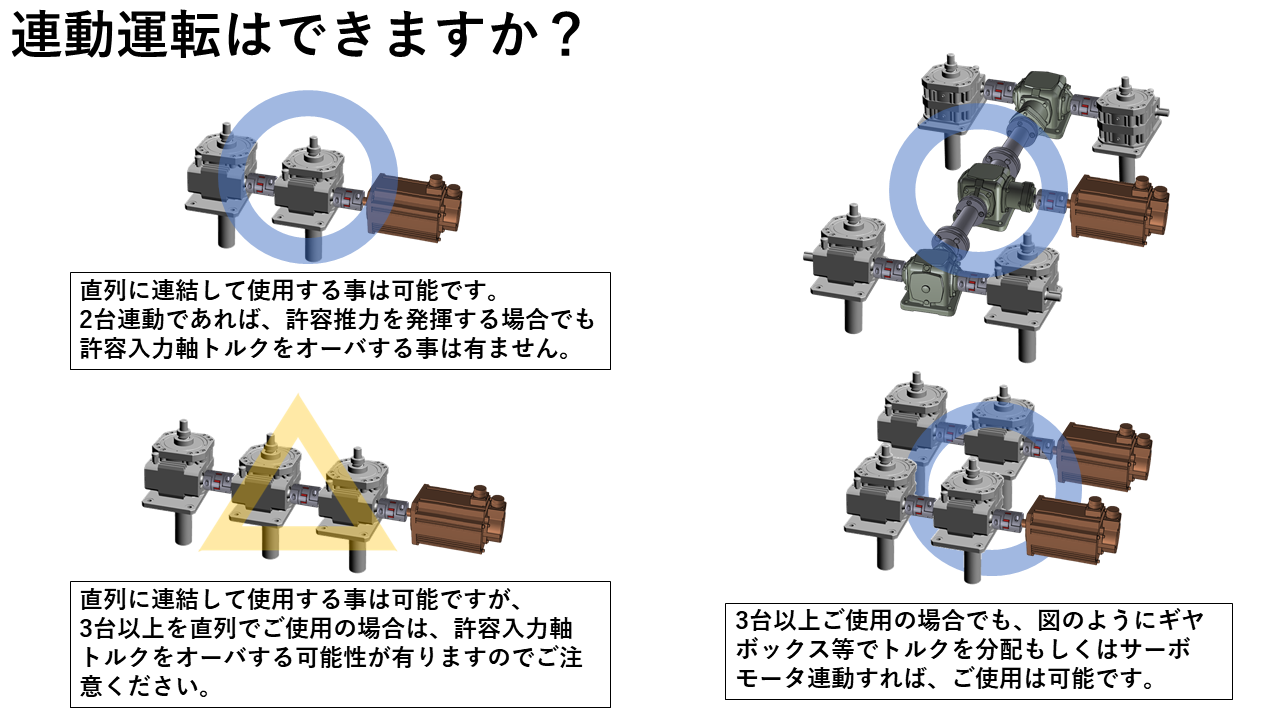

| Q9 | 連動運転は可能ですか? |

| A9 | カップリングやマイタギヤボックスを使って複数台連動させることは可能です。 |

| Q10 | リニスピードジャッキにセルフロック機能は有りますか? |

| A10 | リニスピードジャッキにはセルフロック機能は有りません。 |

| Q11 | ジャバラは何故特形品になるのですか? |

| A11 | リニスピードジャッキは高速運転用ですので、標準的なジャバラでは内部の空気の出入りが伸縮に追い付かず、ジャバラが破裂するかもしれません。 |

| Q12 | オイル潤滑仕様は製作可能ですか? |

| A12 | リニスピードジャッキのギヤはオイル潤滑が標準です。 |

| Q13 | ギヤのグリース潤滑仕様の製作は可能ですか? |

| A13 | グリース潤滑にする事は可能ですが、潤滑性が下がる為、最高速度及び許容頻度でのご使用はできません。 |

| Q14 | クリーンルーム対応は可能ですか? |

| A14 | ネジ軸に低発塵グリース塗布、レイデント処理、及び入力軸防錆メッキなどの対応は可能です。 |

| Q15 | 許容負荷時間率表って、どのように見るのですか? |

| A15 | 形番と周囲温度で参考となる負荷時間率表を選びます。 |

| Q16 | サーボモータのフランジマウントは可能でしょうか? |

| A16 | 176サイズのサーボモータであれば、組合せ可能なものが有りますので、お問合わせください。 |