リフトマスタ® ボールネジタイプ

- ボールネジを採用した片持式リフタ

- ・高効率・高速化

ボールネジの使用により、効率が良く、小さな駆動源で大きな推力を得ることができます。

高効率のため、台形ネジと比較して無理なく装置の高速運転が実現できます。 - ・運転精度・制御性

サーボモータ駆動なども対応可能で多点位置制御や複数の同期運転も可能です。 - ・長寿命

信頼性の高いボールネジを使用しているため、走行寿命予測ができ長寿命です。 - ・豊富なバリエーション

リフトマスタを旋回、アームを傾動させるなど複合的な動きも対応可能です。

特長と構造 動画コンテンツ

採用のメリット

仕様(ボールネジタイプ)

- ・昇降荷重:1.96kN~9.80kN

- ・ストローク:400mm/1,500mm

- ・駆動部:三相モータ付/サーボモータ付

- ・速度:1.5~9.96m/min

許容OHL 荷重曲線(ワーク取付面基準:外形図参照)

カタログ・取扱説明書

形番表示

| LME | B | 0500 | H | 10 | G | E |

| | | リフトマスタ |

| ネジタイプ B:ボールネジ |

| 昇降荷重 0200:1.96kN{200kgf} 0500:4.90kN{500kgf} 1000:9.80kN{1000kgf} |

| 速度 S、H、U 各機種の速度は 詳細情報を ご参照ください。 |

| ストローク 04:400mm 06:600mm 08:800mm 10:1000mm 12:1200mm 15:1500mm |

| 駆動部 G:三相モータ付 K:サーボモータ付 |

| オプション 詳細は下記参照 |

製品形番ナビ

使用しているネジの種類です。

昇降荷重

規定の重心位置にて昇降可能な荷重です。

速度

昇降速度を表す記号です。

各機種の速度値は詳細情報をご参照ください。

ストローク

昇降できる距離です。

駆動部

G:三相モータ付きです。

K:サーボモータ付きです。

オプション記号

J:開口部にジャバラを取り付ける仕様です。

L1~L3:位置検出センサを1個から3個追加します。

V:電源の電圧が倍電圧となります。

E:モータ後部にロータリーエンコーダを装着します。

D1~D3:モータ取付方向を変更します。

D1:標準取付位置に対し90度振り

D2:標準取付位置に対し180度振り

D3:標準取付位置に対し270度振り

製品形番一覧

※形番クリックで詳細情報を表示します。

オプション

前面ジャバラ[オプション記号:J]

・リフトマスタ前面から本体への粉塵侵入を抑制するためのジャバラです。

対応ストローク:400mm~1,200mmまで

※1,200mmを超えるストロークでジャバラ取付をご希望の場合は、ご相談ください。

※LME0200シリーズ・LME0500シリーズのうち、ストロークが800mmと1,200mmの場合のみ、

前面ジャバラ取付時の有効ストロークが短くなります。詳細は、お問合せ下さい。

<取付参考例>

寸法はお問合せください。

[クリックで拡大]

位置検出センサ追加[オプション記号:L1~L3]

・標準品に4個(S速のみ2個)の位置検出センサを備えていますが、

S速のみ3個まで、それ以外の速度では1個のセンサ追加がオプションの対応範囲となります。

・オプション記号は、センサ1個追加で[L1]、2個追加で[L2]、3個追加で[L3]となります。

より多くのセンサ追加をご希望の場合は、ご相談ください。

対応形番 L1 :全標準形番品

L2, L3:LMEB0200S, LMEM0500S, LMEM1000Sのみ

モータ電圧400V級[オプション記号:V]

・駆動用のモータの電圧を400V級に変更します。

対応形番:全標準形番品

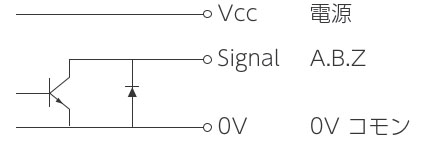

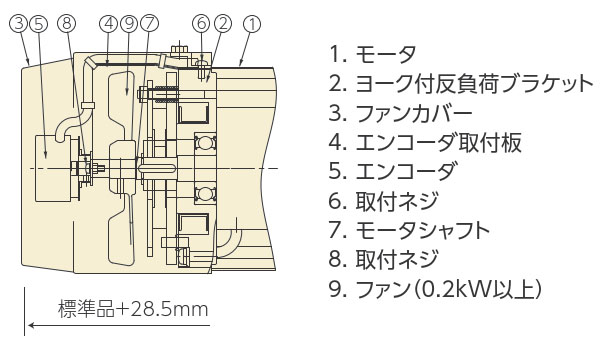

ロータリエンコーダ付[オプション記号:E]

・三相モータ付のモータ反負荷側軸端にロータリエンコーダを組込み、モータの回転信号が出力できるようになります。

対応形番:三相モータ付標準形番品

特長

・制御性

減速機よりオープンコレクタ出力信号が取出せますので、さまざまな運転が可能になります。

・コンパクト

モータ軸とロータリエンコーダをカップリングで接続する必要がありません。

・コストダウン

従来の別置きと比べ、カップリング・ベースプレートやレベル合わせ作業が不要です。

ロータリエンコーダ部仕様

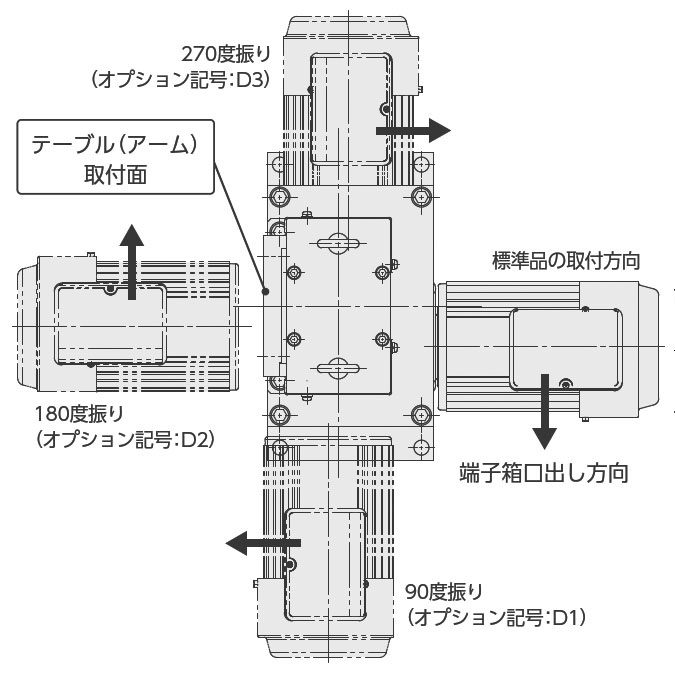

モータ取付方向変更[オプション記号:D1~D3]

・装置の設置場所やワークの取付、搬送物の受け渡し方向などに応じて、モータの取付方向を変えることができます。

※モータの取付方向とストロークによって、全高寸法が変更となる場合があります。

※LME0200Sシリーズはモータが上部についていますので、どの向きでも床との接地面の面積は、標準品と同じ寸法となります。

モータ部やフランジ部がガイド部からはみだす寸法については、お問合せください。

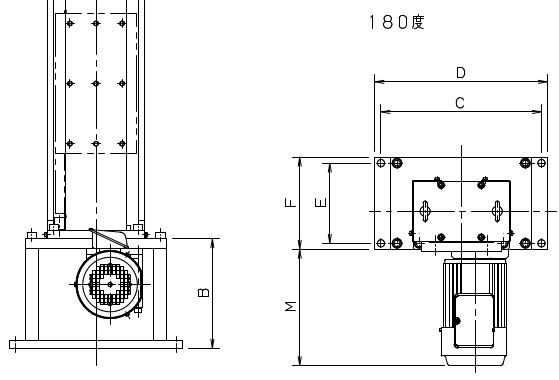

※下記の図面・寸法表は三相モータ付の仕様について掲載しています。サーボモータ付もオプション対応しますので、ご相談ください。

対応形番:全標準形番品

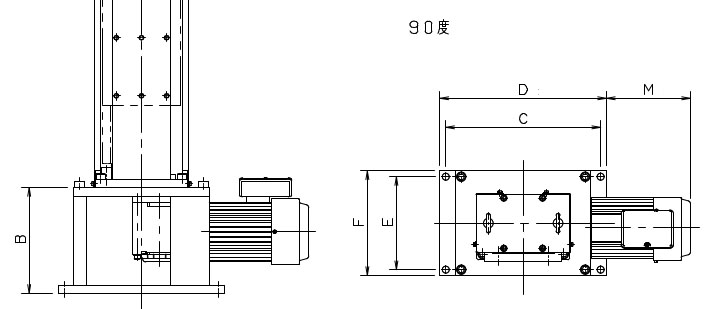

D1:モータ取付方向変更 90度振り

D2:モータ取付方向変更 180度振り

D3:モータ取付方向変更 270度振り

| 形式 | モータ容量 kW |

モータ取付方向標準 | D1:90度振り | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | C | D | E | F | M | B | C | D | E | F | M | ||

| 0200S | 0.1 | - | 250 | 280 | 170 | 200 | 141 | - | 250 | 280 | 170 | 200 | 154 |

| 0200H | 0.4 | 245 | 340 | 370 | 193 | 245 | 340 | 370 | 190 | 220 | 160 | ||

| 0500S | 0.4 | ||||||||||||

| 0500H | 0.75 | 270 | 270 | 210 | 240 | 237 | |||||||

| 0500U | 1.5 | 273 | 400 | 430 | 200 | 230 | 369 | 318 | 400 | 430 | 255 | 285 | 283 |

| 1000S | 0.75 | 250 | 273 | 240 | 270 | 217 | |||||||

| 1000H | 1.5 | 368.5 | 318 | 255 | 285 | 293 | |||||||

| 1000U | 2.2 | 407 | 343 | ||||||||||

| 形式 | モータ容量 kW |

モータ取付方向標準 | D2:180度振り | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | C | D | E | F | M | B | C | D | E | F | M | ||

| 0200S | 0.1 | - | 250 | 280 | 170 | 200 | 141 | - | 250 | 280 | 170 | 200 | 172 |

| 0200H | 0.4 | 245 | 340 | 370 | 193 | 245 | 340 | 370 | 223 | ||||

| 0500S | 0.4 | ||||||||||||

| 0500H | 0.75 | 270 | 265 | 300 | |||||||||

| 0500U | 1.5 | 273 | 400 | 430 | 200 | 230 | 369 | 273 | 400 | 430 | 200 | 230 | 366 |

| 1000S | 0.75 | 250 | 290 | ||||||||||

| 1000H | 1.5 | 368.5 | 366 | ||||||||||

| 1000U | 2.2 | 407 | 416 | ||||||||||

| 形式 | モータ容量 kW |

モータ取付方向標準 | D3:270度振り | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | C | D | E | F | M | B | C | D | E | F | M | ||

| 0200S | 0.1 | - | 250 | 280 | 170 | 200 | 141 | - | 250 | 280 | 170 | 200 | 80 |

| 0200H | 0.4 | 245 | 340 | 370 | 193 | 245 | 340 | 370 | 190 | 220 | 86 | ||

| 0500S | 0.4 | ||||||||||||

| 0500H | 0.75 | 270 | 270 | 210 | 240 | 163 | |||||||

| 0500U | 1.5 | 273 | 400 | 430 | 200 | 230 | 369 | 318 | 400 | 430 | 255 | 285 | 209 |

| 1000S | 0.75 | 250 | 273 | 240 | 270 | 123 | |||||||

| 1000H | 1.5 | 368.5 | 318 | 255 | 285 | 199 | |||||||

| 1000U | 2.2 | 407 | 249 | ||||||||||

選定

ご使用条件・ご希望条件に該当するリフタを担当者が選定します。

本ページ上部の「選定計算」のタブをクリックしてください。

特殊仕様品

壁取付仕様

リフトマスタが床面設置できない場合には、壁取付仕様にも対応可能です。強固な装置フレーム側面などを有効活用し、省スペース化が図れます。

落下防止仕様

リフトマスタに手動式の落下防止ピンを取付けることで落下防止に対応します。

旋回軸仕様

ワーク取付部に手動式旋回機構を設けます。

低床仕様

スペースの問題でリフトマスタを設置できない場合にも、高さを抑えた仕様で対応可能です。

高速仕様

MAX 500mm/sの高速仕様です。モータはサーボモータを支給してください。詳細は当社までお問い合わせください。 ※300mm/secまでの高速仕様は、インバータ制御により汎用モータで運転が可能です。

防塵防滴仕様

防塵性能、防滴性能を備えたリフトマスタです。切削油やクーラントなどの飛散する雰囲気にも対応可能です。 ※屋外仕様ではありません。

水平搬送機構

水平搬送のリフトマスタも製作可能です。

高剛性仕様

昇降時の揺れや、停止時のたわみなどが問題となる場合には、支柱本体を強化した仕様で対応可能です。

ラインシャフト同期タイプ

リフトマスタをつばき製のエクトフレックスカップリング、マイタギヤボックスと連結し、同期運転を可能にします。ギヤモートルを含め、使用条件に合ったシステムを提供します。