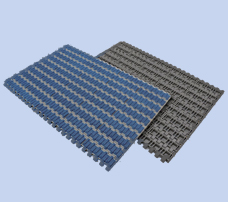

プラスチックモジュラーチェーン WT2525-M形

- チェーンピッチ

25.4mm - 直線搬送用

- クローズタイプ

- WT2520シリーズ固定幅タイプに100mm幅のクローズタイプをラインアップ

- チェーン幅100mmの採用により、コンベヤベルトからの置換に最適です。

- チェーン表面が緩やかな凸形状のため、段積された重量シートが表面の凸形状に微かに食い込むことで滑りを防止します。

特長

-

・チェーン幅100mmの採用により、コンベヤベルトからの置換に最適

-

・扱いやすさを追求した表面形状

チェーン表面が緩やかな凸形状のため、段積された重量シートが表面の凸形状に微かに食い込むことで滑りを防止します。

[切出搬送イメージ]

-

・乗継スペースを削減

コンベヤ端部にΦ50の丸棒を設置することで乗継スペースを小さくすることが可能です。

この場合正逆底部駆動?となります。

注)突合せ部での巻込み防止のため、安全防止器具(安全カバー等)を取り付けてください。

[突合せレイアウト]

×(ドラッグで移動できます)

×(ドラッグで移動できます)正逆底部駆動とは?

正逆とはモータの正転(前進)、逆転(後退)のことを指します。そうすることで搬送物を前進、後退できます。

底部駆動とは駆動部(駆動用のスプロケット、モータ)の位置が搬送面に対して下→底にあることです。

上記2つを総称し正逆底部駆動といいます。

-

・クローズタイプとの組合せ編成可能

WT2525VG-M形(ラバータイプ)とWT2525-M形(クローズタイプ)は組合せ編成が可能です。

注)組合せ編成をご希望される場合は当社までお問合せください。

[組合せ編成]

-

・メンテナンス時間の短縮が可能

ピン+プラグ止め方式を採用しているため、チェーンの切継ぎ作業が容易で部分補修が可能です。

■用途

下記は当社が推奨する業界です。

搬送能力(コンベヤ速度)・搬送物(重量、形状)・環境・用途などにより使用できない場合があります。

選定の際の目安としてご活用ください。

記載されていない用途・条件がございましたら当社まで問合せください。

推奨業界/搬送物サイズ (●:推奨 ○:使用可能 △:搬送条件により異なります)

| 搬送サイズ (重量) |

業界 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 製缶 | 飲料 | タイヤ | 機械部品関連 | 物流 | 薬品 | 製パン・食品 | 二次電池 | 半導体・ 太陽光パネル関連 |

|

| 大 | △ | ○ | △ | ○ | ○ | △ | △ | ○ | △ |

| 中 | △ | ○ | △ | ○ | ○ | △ | ○ | ○ | △ |

| 小 | △ | ● | △ | ● | ● | △ | ● | ● | △ |

用途

- ■段ボールの切出し搬送

- ■シート自動供給装置

- ■段積みシート直角搬送

商品一覧

※形式クリックで詳細情報を表示します。

| チェーンピッチ mm | 25.4 |

|---|---|

| 用途 | 直線搬送用 |

| チェーンタイプ | クローズタイプ |

| - | |

| 本体チェーン仕様 | - |

| ピンタイプ | - |

| ピン材質 | - |

| ピン形状 | - |

| トッププレート厚み mm | - |

| プッシャ材質 | - |

| その他機能 | - |

| 形式 | WT2525-M |

|

|

| チェーン幅 mm | 100 |

カタログ・取扱説明書

その他WT2500シリーズ

形番表示例

| WT | 25 | 25 | - | M100 | - | G | + | 80L |

| | 形式 |

| チェーンピッチ 25:25.4mm |

| | | | |

| | | チェーン幅 |

| 仕様記号 |

| リンク数 最小数2、最大数99999 |

|||

| リンク形状 |

M:固定幅

100:100mm |

|||||||

| 25:クローズタイプ | ||||||||