製品情報 直動機器

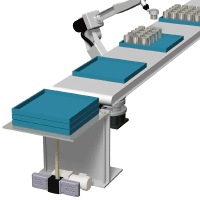

つばきの直動機器は、高品質な自社製ネジを使用している電動式のシリンダとジャッキ、当社独自のジップチェーン駆動のジップチェーンアクチュエータをラインアップしています。

ネジ機構とジップチェーン機構のいずれも、製品の持つ特長を最大限に活かし、高速・高頻度の運転や高い精度が求められる運転など、幅広い用途でご使用いただけます。

※ジップチェーン機構とは、2本のチェーンがジッパーのように噛み合うことで、1本の強固な柱状となり「押し・引き」で使用できる当社独自の技術です。

直動機構の種類

ジップチェーン機構

- 高速

- 高頻度

- 高耐久性

- コンパクト

つばきの独自技術「ジップチェーン」を用いた機構です。

コンパクト性に優れ、高タクト運転に求められる高速・高頻度・耐久性を持っています。

2本のチェーンを噛合せ1本の棒状にすることで、押し引きを可能にしました。

ジッパーのように噛合う様子からジップチェーンと名づけました。

(ジップチェーン機構の特設サイトはこちら)

ボールネジ機構・台形ネジ機構

- 高頻度

- 大許容荷重

- 静粛性

ボールネジ機構

ネジ軸とナットの間に鋼球を入れ、転がり摩擦することで、高効率で動作できるようにした機構です。

台形ネジ機構に比べて高速・高頻度用途に適しているので、生産性が求められる組立ラインなどに適しています。

また、高効率なので駆動源を小形化することができます。

信頼性の高い内製のボールネジを使用しているため、走行寿命の予測も可能です。

ボールネジ1回転当たりの進む距離(リード)が通常のボールネジより長いものをハイリードボールネジと呼び、通常のボールネジと同じ入力回転速度でも高速化が実現できます。

台形ネジ機構

ネジ軸とナットが滑り摩擦することで動作する機構で、メンテナンス用途などの低速・低頻度での運転に向いています。

ボールネジ機構にはないセルフロック性を有しているので、荷重保持が可能です。

また、構造がシンプルなため経済的です。

つばきの直動機器製品群

| 電動シリンダ:パワーシリンダ | スクリュージャッキ: リニパワージャッキ |

ボールネジ昇降ユニット: リニスピードジャッキ |

噛合チェーン式アクチュエータ: ジップチェーンアクチュエータ |

||

|---|---|---|---|---|---|

|

|

|

|

||

| 機構の種類 | ボールネジ 台形ネジ |

ボールネジ ハイリード ボールネジ |

台形ネジ | ボールネジ | ジップチェーン |

| 目的 | 負荷の押し引き | 負荷の押し引き | 負荷の保持 | 負荷の押し引き | 負荷の押し引き |

| 特長 | モータ一体型で簡単配線 クリーンな環境を実現 |

各種ねじタイプを選択可 | 高速・高頻度、低床、長寿命 | 他機構を圧倒する高速・高頻度、 低床、長寿命 |

|

| 推力 | 最大490kN | 4.90kN~980kN | 1.96kN~980kN | 15kN~50kN | 400N~2000N |

| ストローク | 最大2000mm | 最大2000mm | 最大1500mm | 最大2000mm | |

| 速度・運転頻度 | 最大速度:333mm/s 負荷時間率:50%ED※1 |

ネジ軸最大速度: 50~120mm/s※2 許容負荷時間率: 30%ED |

ネジ軸最大速度: 40mm/s 許容負荷時間率: 20%ED |

ネジ軸最大速度:200mm/s 許容負荷時間率:100%ED※3 |

最大速度:1000mm 負荷時間率:100%ED |

| 用途例 |

傾動装置

ストッパ |

テーブル昇降

圧延ロール |

トラバーサの

取出し |

段積・段ばらし

パレットの |

|

- ※1 エコシリーズ サーボタイプの場合

- ※2 ネジタイプによって異なります

- ※3 条件により異なります

直動機器製品一覧

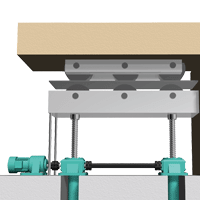

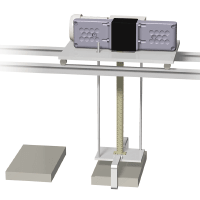

ボールネジまたは台形ネジとウォームギヤの組み合わせで構成されたスクリュージャッキです。

スクリュージャッキとは、駆動機の回転をネジ・ナット機構によって推進力に変換することで、ネジ軸を前後に動かす直動機構です。

負荷を押し引きすることが目的のシリンダとは異なり、搬送物の昇降・位置決めなど、主に負荷を保持する用途で使用されます。

つばきのリニパワージャッキは、内蔵のウォームギヤでネジを昇降させる機構で、駆動用のモータとつなぐだけで運転可能です。

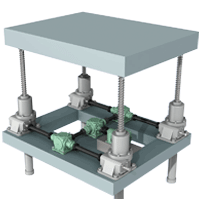

カップリングやマイタ・ベベルギヤボックスを用いた複数台連動にも対応しています。

また、下記のように様々なタイプ・仕様をご用意しております。「痒い所に手が届く」リニパワージャッキをご提供可能です。

- ・ネジが回転してナットが昇降するのでピットの設置が不要なトラベリングナットタイプ

- ・ネジはボールネジ(高速・高頻度)、ハイリードボールネジ(超高速・高頻度)、台形ネジ(低速・荷重保持)の3タイプ

- ・クリーンルームに最適な低発塵仕様、ネジ軸のステンレスネジ仕様(台形ネジのみ)、レイアウトに自由度が増す左ネジ仕様(台形ネジのみ)

JWB (ボールネジタイプ)

形番 JWB~

JWB(ボールネジタイプ)は転がり摩擦で、省エネルギー運転が可能なスクリュージャッキです。

- ・主な構成部品は精密ボールネジと高精度ウォームギヤです。

- ・高効率:

ボールネジのため効率が良く、小さな駆動源で大きな推力が得られます。 - ・速度アップ:

台形ネジタイプと比較してネジの効率アップにより、無理なくより速い速度での運転が実現できます。 - ・長寿命:

信頼性の高いボールネジを使用しているため、長寿命です。 - ※セルフロックを有していませんのでブレーキが必要です。

基本容量 kN

4.90~980

ネジの種類

ボールネジ

ストロークmm

100~2000

JWH (ハイリードボールネジタイプ)

形番 JWH~

JWH(ハイリードボールネジタイプ)はハイリードボールネジの採用により、JWBタイプと同じ入力回転速度でさらに高速化が可能なスクリュージャッキです。(最大4倍)

- ・主な構成部品はハイリードボールネジと高精度ウォームギヤです。

- ・高速化:

信頼性の高いハイリードボールネジの採用により、ネジ軸速度は最高7.5m/minでの運転が可能です。 - ・低騒音:

JWB(ボールネジタイプ)より同一速度の場合、駆動源に減速ユニットを用いて入力回転速度を低く

できるので、ジャッキの低騒音化が可能です。 - ※セルフロックを有していませんのでブレーキが必要です。

基本容量 kN

9.80~196

ネジの種類

ハイリードボールネジ

ストロークmm

100~2000

JWM (台形ネジタイプ)

形番 JWM~

JWM(台形ネジタイプ)は低速、低頻度に適した標準タイプのスクリュージャッキです。

- ・主な構成部品は、調心性台形ネジと高精度ウォームギヤです。

- ・経済的:

シンプルでコンパクトな構造により経済的です。 - ・低速・低頻度:

滑り接触の台形ネジ特性を活かし、低速・低頻度の用途に最適です。 - ・荷重保持:

台形ネジは計算上セルフロック性を有しており、荷重保持が期待できます。

※振動、衝撃などによりセルフロックが効かなくなる場合があります。 - ・ステンレスネジ仕様を品揃え:

JWM025とJWM050の2機種について、オーステナイト系ステンレスでネジ軸を標準化しました。 - ・左ネジ仕様を品揃え:

入力回転方向が同じで、右ネジ仕様とは反対にネジが動きます。

基本容量 kN

1.96~980

ネジの種類

台形ネジ

ストロークmm

100~2000

各シリーズの使い分けにあたっては、下記資料もご参照ください。

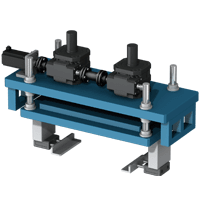

ジャッキシステムの構築に必要なカップリング・ギヤボックスなどの一括選定が可能です。

スクリュージャッキの基礎知識

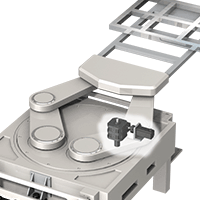

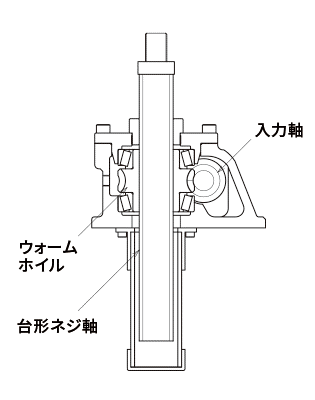

構造

ボールネジタイプ

台形ネジタイプ

主に以下の要素で構成されています。

- 入力軸:

モーターなどの駆動源と接続される軸で、通常はウォームギヤが切られています。このウォームを介してウォームホイールにトルクが伝達されます。 - ウォームホイール:

ウォームからのトルクを受け取り、減速しながらトルクを増加させます。 - ナット:

ウォームホイールと一体化しており、ウォームとウォームホイールによって増幅されたトルクをネジ軸(ボールねじまたは台形ねじ)に伝達します。 - ネジ軸:

ナットから伝えられたトルクを、ネジ山を介して直線的な推進力に変換します。