セレクションガイド 大形コンベヤチェーン

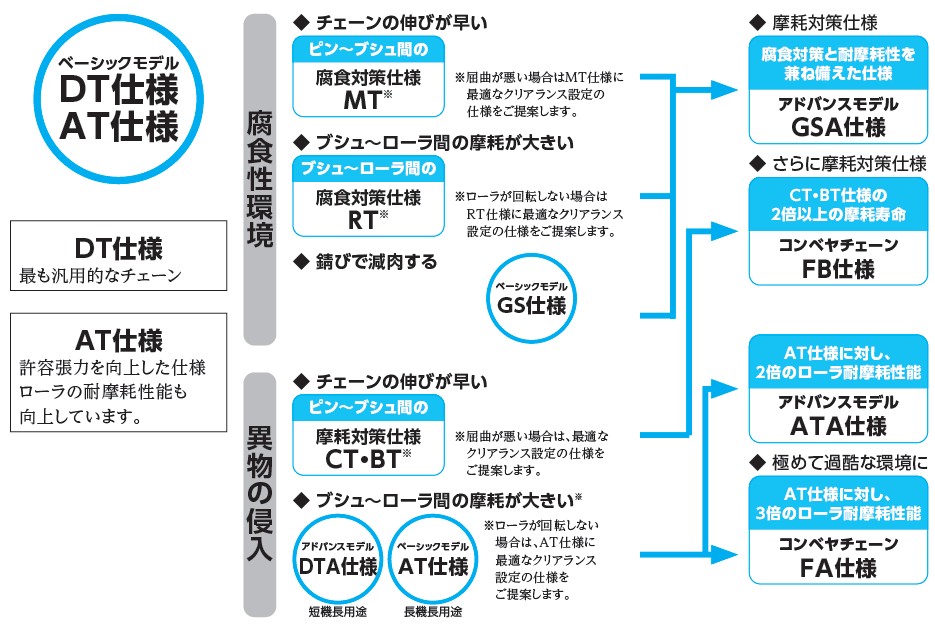

大形コンベヤチェーン DT仕様

形番 RF□□□□□R・F・S・M・N-DT~

もっとも経済的な汎用コンベヤチェーンです。(ベーシックモデル)

- ・メートルピッチ系とインチピッチ系をラインアップしています。

- ・各種アタッチメントをご用意できます。

- ・ピン、ブシュには熱処理を施していますが、プレートには施行していません。

- ・使用温度雰囲気:-20℃~200℃

サイズ

RF03トン~RF120トン

RF430~RF212

アタッチメント種類

A1, A2, A3, K1, K2, K3, GA2, GA4 など

ローラ形式

Rローラ, Fローラ,

Sローラ, Mローラ

大形コンベヤチェーン DTA仕様

形番 RF□□□□□R・F-DTA~

汎用大形コンベヤチェーンDT仕様の耐摩耗性能を向上。(アドバンスモデル)

- ・DT仕様に対し、ブシュ~ローラ間の耐摩耗性能を3倍に向上した仕様です。

- ・Rローラ、Fローラのみの対応となります。

- ・使用温度雰囲気:-20℃~200℃

【長寿命】

サイズ

RF03トン~RF36トン

インチ系は

お問合せください

アタッチメント種類

A1, A2, A3, K1, K2, K3, GA2, GA4 など

ローラ形式

Rローラ, Fローラ

大形コンベヤチェーン AT仕様

形番 RF□□□□□R・F・S・M・N-AT~

汎用コンベヤチェーン(DT仕様)に比べ、約2倍の最大許容張力を有し、ブシュ~ローラ間の

耐摩耗性及びローラ許容負荷を向上。(ベーシックモデル)

- ・メートルピッチ系とインチピッチ系をラインアップしています。

- ・各種アタッチメントをご用意できます。

- ・使用雰囲気温度:-20℃*~400℃

※-20℃以下でのご使用については当社までお問い合わせください。

サイズ

RF03トン~RF440トン

RF430~RF212

アタッチメント種類

A1, A2, A3, K1, K2, K3, GA2, GA4 など

ローラ形式

Rローラ, Fローラ,

Sローラ, Mローラ,

Nローラ

大形コンベヤチェーン ATA仕様

形番 RF□□□□□R・F-ATA~

AT仕様の上位仕様です。耐摩耗性・最大許容張力を向上させています。(アドバンスモデル)

- ・AT仕様に対し、さらにブシュ~ローラ間の耐摩耗性能が2倍、ピン~ブシュ間の耐摩耗性能が1.5倍、

最大許容張力が1.2倍に向上しています。 - ・RF08~RF36サイズ、Rローラ・Fローラのみに対応。

- ・使用雰囲気温度:-20℃*~200℃

※-20℃以下でのご使用については当社までお問い合わせください。

【長寿命】【高強度】

サイズ

RF08トン~RF36トン

インチ系は

お問合せください

アタッチメント種類

A1, A2, A3, K1, K2, K3, GA2, GA4 など

ローラ形式

Rローラ, Fローラ

大形コンベヤチェーン GS仕様

形番 RF□□□□□R・F・S・M-GS~

DT仕様に対し、耐食性を向上させたステンレス製チェーン(ベーシックモデル)

- ・汎用大形コンベヤチェーンDT仕様に対し、耐食性を向上させています。

- ・材質はステンレス(ステンレス400シリーズ)を採用しています。

- ・使用温度雰囲気:-20℃*~400℃

- ※-20℃以下でのご使用については当社までお問い合わせください。

サイズ

RF03トン~RF26トン

RF430~RF212

アタッチメント種類

A1, A2, A3, K1, K2, K3, GA2, GA4 など

ローラ形式

Rローラ, Fローラ,

Sローラ, Mローラ,

Nローラ

大形コンベヤチェーン GSA仕様

形番 RF□□□□□R・F・S・M-GSA~

GS仕様の上位仕様です。耐摩耗性・最大許容張力を向上させています。(アドバンスモデル)

- ・GS仕様に対し、ブシュ~ローラ間の耐摩耗性能が2倍、ピン~ブシュ間の耐摩耗性能が1.5倍、

最大許容張力、Rローラ、Fローラ許容負荷が1.3倍に向上しています。 - ・使用雰囲気温度:-20℃*~200℃

- ※-20℃以下でのご使用については当社までお問い合わせください。

【長寿命】【高強度】

サイズ

RF03トン~RF26トン

インチ系は

お問合せください

アタッチメント種類

A1, A2, A3, K1, K2, K3, GA2, GA4 など

ローラ形式

Rローラ, Fローラ,

Sローラ, Mローラ

大形コンベヤチェーン SS仕様

形番 RF□□□□□R・F・S・M-SS~

GS仕様の上位仕様です。耐食性、耐薬品性、耐熱性、耐寒性に優れたステンレス製チェーン

です。(ベーシックモデル)

- ・材質はステンレス(ステンレス300シリーズ)を採用しています。

- ・使用温度雰囲気:-20℃*~400℃

- ※-20℃以下でのご使用については当社までお問い合わせください。

サイズ

RF03トン~RF26トン

RF430~RF212

アタッチメント種類

A1, A2, A3, K1, K2, K3, GA2, GA4 など

ローラ形式

Rローラ, Fローラ,

Sローラ, Mローラ

大形コンベヤチェーン SSA仕様

形番 RF□□□□□R・F・S・M-SSA~

SS仕様のブシュ~ローラ間の耐摩耗性能を向上させています。(アドバンスモデル)

- ・SS仕様に対し、ブシュ~ローラ間の耐摩耗性能を1.5倍に向上した仕様です。

- ・Rローラ、Fローラのローラ許容負荷も1.3倍に向上しています。

- ・使用温度雰囲気:-20℃~200℃

【長寿命】

サイズ

RF03トン~RF26トン

インチ系は

お問合せください

アタッチメント種類

A1, A2, A3, K1, K2, K3, GA2, GA4 など

ローラ形式

Rローラ, Fローラ,

Sローラ, Mローラ

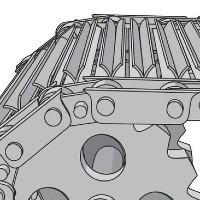

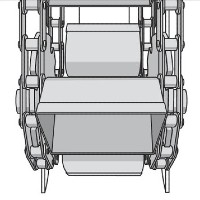

耐荷重大形コンベヤチェーン(ベアリングローラコンベヤチェーン)

ベアリングローラコンベヤチェーンはローラ内に円筒コロを入れた独自の構造により、チェーン走行抵抗の低下・ローラ許容負荷の大幅向上・ブシュ~ローラ間の摩耗寿命の

向上を実現、従来のコンベヤチェーンでは解決が困難であった「高効率化」「コストダウン」「シャクリ現象*の抑制」「ローラ・レールの長寿命化」を実現します。

標準仕様に加えて耐粉塵使仕様、無給油仕様、無給油耐水仕様等を品ぞろえしており、求められる用途に合わせてお選びいただけます。

*駆動部が連続運転しているにもかかわらず、チェーンが移動、停止を繰り返す現象

切継ぎがトルクレンチ一つで完了する便利な継手リンク スクリューロックリンクもご用意。詳しくはこちら

1. ベアリングローラの構造

2. ベアリングローラの機能

- ・チェーン走行抵抗の低減(汎用品の1/3)

- ・ローラ許容負荷の大幅アップ

3. ベアリングローラの効果

- ・チェーン張力・所要動力の低減

- ・長機長・低速運転時のシャクリ防止

- ・ローラ回転不良の抑制とレール摩耗の低減

- ・摩耗寿命の向上(ブシュ~ローラ間)

- ・CO2排出量・電気代の削減

製品ラインアップ

ベアリングローラコンベヤチェーン 標準仕様

形番 RF□□□□□BR・BF-DT・AT~

ローラ内部に円筒コロを入れた当社独自の構造により、汎用コンベヤチェーン(DT仕様)の

約5倍の摩耗寿命を持ちます。

- ・モータ所要動力約1/3、チェーンサイズの2サイズダウンが可能です。

- ・設備全体のコストダウンに貢献します。

- ・RFコンベヤチェーンのRローラ、Fローラと同一寸法です。

- ・使用雰囲気温度:BR, BF: -20℃~80℃

【消費電力1/3】【汎用品より長寿命】

サイズ

RF03トン~RF36トン

インチ系は

お問合せください

アタッチメント種類

A1, A2, A3, K1, K2, K3

ローラ形式

BRローラ, BFローラ

ベアリングローラコンベヤチェーン 耐粉塵仕様

形番 RF□□□□□DBR・DBF-DT・AT~

ラビリンス構造とシールを用いることにより、ベアリングローラコンベヤチェーン標準仕様に比べて粉塵が侵入し難いコンベヤチェーンです。

- ・ラビリンス構造とシールを用いることにより、粉塵が侵入し難く、粉塵雰囲気では標準仕様の3倍の摩耗寿命があります。

- ・DBR、DBFの2種類のローラ形式があります。

- ・使用雰囲気温度:-10℃~80℃

【消費電力1/3】【粉塵雰囲気でも長寿命】

サイズ

RF10トン~RF36トン

インチ系は

お問合せください

アタッチメント種類

A1, A2, A3, K1, K2, K3

ローラ形式

DBRローラ, DBFローラ

ベアリングローラコンベヤチェーン 無給油一般仕様

形番 RF□□□□□EBR・EBF-DT・AT~

ブシュとローラ間に自己潤滑機能を持った特殊円筒コロを採用しているため、ローラ部は

無給油で使用できます。追加給油も不要です。

- ・EBR、EBFの2種類のローラ形式があります。

- ・使用雰囲気温度:-20℃~50℃

- ※標準シリーズとは最大許容張力が異なりますので、選定時にはご注意ください。ローラ許容負荷は同じです。

【消費電力1/3】【追加給油不要で長寿命】

サイズ

RF03トン~RF36トン

インチ系は

お問合せください

アタッチメント種類

A1, A2, A3, K1, K2, K3

ローラ形式

EBRローラ, EBFローラ

ベアリングローラコンベヤチェーン オール無給油仕様

形番 RF□□□□□AEBR・AEBF-DT・AT~

ピン~ブシュ間、ブシュ~ローラ間ともに追加給油不要で使用できます。

- ・ローラ内部にスチール製コロと特殊円筒コロを交互に設置。

さらにブシュ内面に固体潤滑材を圧着、シールで封入することで、ピン~ブシュ間・ブシュ~ローラ間ともに追加給油不要で使用可能になっています。 - ・AEBR、AEBFの2種類のローラ形式があります。

- ・標準シリーズとは最大許容張力が異なりますので、選定時にはご注意ください。ローラ許容負荷は同じです。

- ・使用雰囲気温度:-20℃~50℃

【消費電力1/3】【追加給油不要でも長寿命】

サイズ

RF05トン~RF26トン

インチ系は

お問合せください

アタッチメント種類

A1, A2, A3, K1, K2, K3

ローラ形式

AEBRローラ, AEBFローラ

ベアリングローラコンベヤチェーン 無給油耐水仕様

形番 RF□□□□□WEBR・WEBF-GS~

ローラ内部にステンレス製コロと特殊円筒コロを交互に入れることで、水のかかる雰囲気に

おいて追加給油不要で使用できます。

- ・WEBR、WEBFの2種類のローラ形式があります。

- ・使用温度範囲:0℃~50℃

【消費電力1/3】【水がかかる雰囲気でも長寿命】

サイズ

RF03トン~RF36トン

インチ系は

お問合せください

アタッチメント種類

A1, A2, A3, K1, K2, K3

ローラ形式

WEBRローラ, WEBFローラ

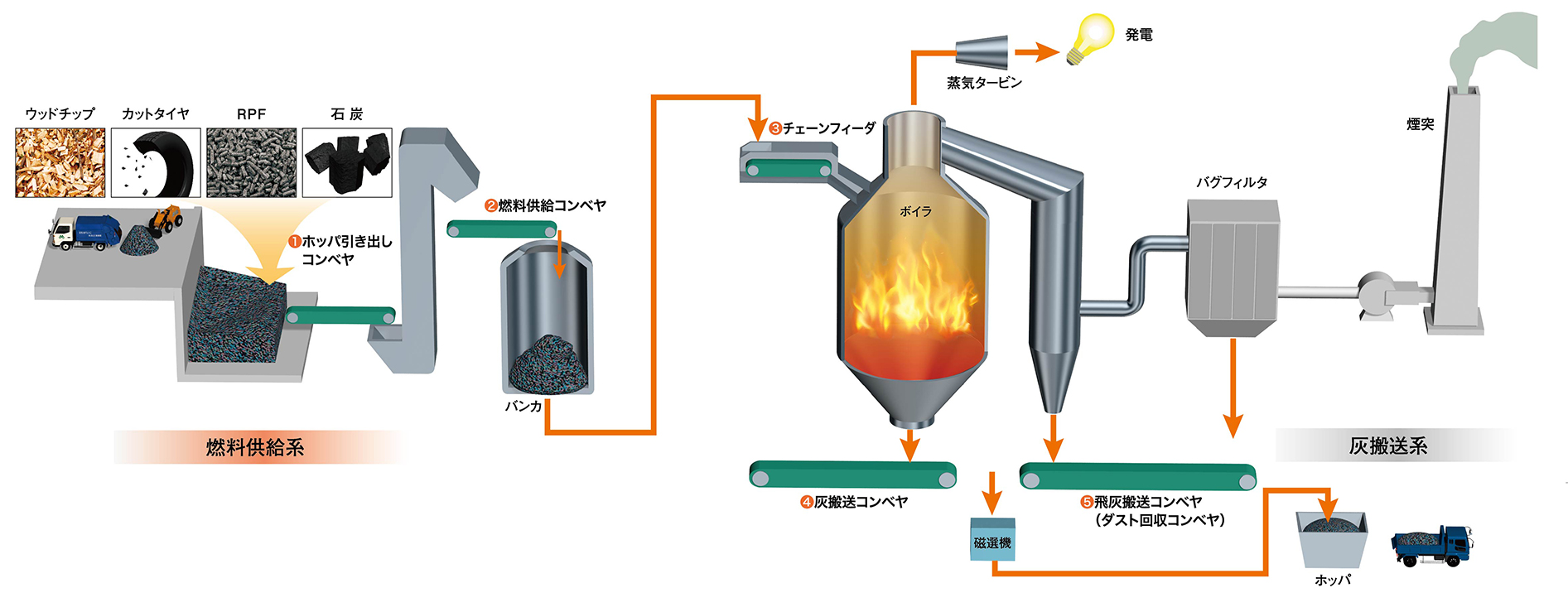

業界特化商品

各業界特有のコンベヤの実績をまとめ、業界特化商品をラインアップしています。

該当業界以外にも各仕様を応用できますのでお問合せください。

セメント業界

鉄鋼業界

(超重量物搬送)

バイオマス発電施設

ゴミ処理施設

食品業界

水処理施設

自動車業界

セメント業界

「原料」「焼成」「仕上げ」各工程に特化したコンベヤチェーン

- 原料工程

- 焼成工程

- 仕上工程

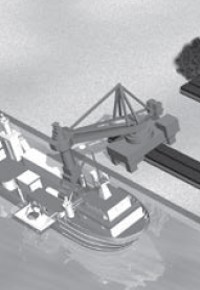

リクレーマ設備

リクレーマ設備

貯蔵されたバラモノを連続してかき取り次工程に供給する設備専用のチェーンです。大荷重が作用し、ローラの摩耗が早い場合があります。

リクレーマ専用チェーンは、搬送物や諸条件により専用設計されたチェーンです。

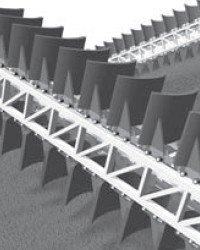

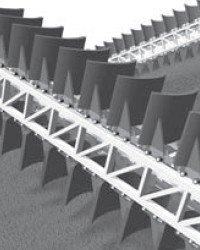

エプロンコンベヤ

エプロンコンベヤ

原料や燃料などをエプロン上に載せて搬送するコンベヤ用のチェーンです。粉塵などの影響でローラの摩耗が大きくなります。

| 一般 (ベーシックモデル) |

対策仕様 (アドバンスモデル) |

|

|---|---|---|

| 短機長 | DT仕様 | DTA仕様 |

| 短機長 | AT仕様 | ATA仕様 |

さらに長寿命を図りたい場合はベアリングローラコンベヤチェーン耐粉塵仕様をご検討ください。

ケーキ搬送

屋外コンベヤ

クリンカ搬送コンベヤ(ドラグコンベヤ)

燃料搬送

フローコンベヤ

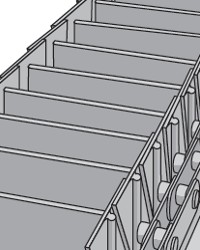

フローコンベヤ

密閉ケースで粉粒体を搬送する専用チェーンです。搬送物に応じて各種アタッチメントを選択いただけます。

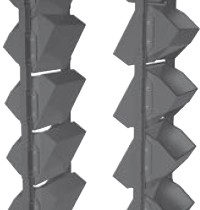

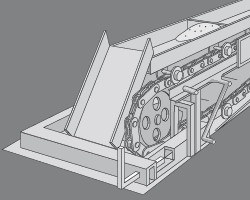

バケットエレベータ

バケットエレベータ

密閉ケースで粉粒体を持ち上げて搬送するチェーンです。耐摩耗性と疲れ強さに重点をおいてます。

製品搬送

ダスト回収コンベヤ

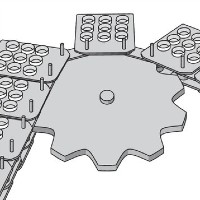

特殊スプロケットブロック替歯タイプ

鉄鋼業界(超重量物搬送)

「大荷重」「高速」「高温」…様々な用途で使われるコンベヤチェーン

- ①②原料ヤード

- ③焼結鉱工場

- ④製銑ヤード

- ⑤圧延ヤード

- ⑥製品ヤード

- 高炉

- コークス工場

- 冷延ヤード

①連続チェーン式アンローダ

①連続チェーン式アンローダ

②チェーンスクレーパ式リクレーマ

②チェーンスクレーパ式リクレーマ

貯蔵されたバラモノを連続してかき取り、次工程に供給する設備専用のチェーンです。

大荷重が作用し、ローラの摩耗が早い場合があります。

リクレーマ専用チェーンは、搬送物や諸条件により専用設計されたチェーンです。

③焼結鉱搬送パンコンベヤ

③焼結鉱搬送パンコンベヤ

④連続鋳造工程

⑤圧延工程

⑥コイル・トランスファ

⑥コイル・トランスファ

ローラとブシュの間にコロ軸受を採用し、

走行抵抗を小さくしています。

これにより重量物の搬送も行えます。

サドル部は搬送形態に合わせて製作します。

高温搬送物【製鋼・圧延】

常温搬送物【製鋼・熱延】

常温搬送物【製鋼・熱延】

ビレット・コイルなどの大荷重搬送

ビレット・棒鋼搬送ローラの摩耗が早い

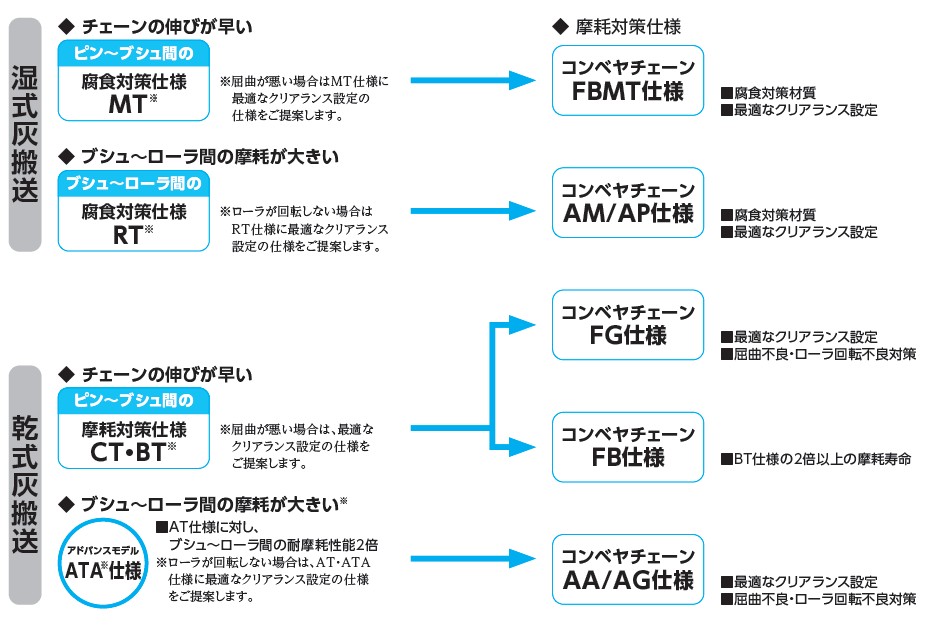

ゴミ処理施設

工程ごとに異なる「過酷な条件」に最適なコンベヤチェーン。

- ①受入・供給コンベヤ

- ②灰出しコンベヤ

- ③飛灰コンベヤ

- ④溶融スラグコンベヤ

| ①受入・供給コンベヤ | ②灰出しコンベヤ | ③飛灰コンベヤ | ④溶融スラグコンベヤ | |||

|

収集したゴミを搬送する最初のラインです。ここでは、ゴミ投入時の衝撃や搬送物の高負荷がかかる場合があります。 受入・供給コンベヤ用

・搬送物:収集したゴミ |

焼却後の灰を搬送するラインです。焼却後冷却のために水中に落とし込まれた灰を搬送する場合もあります。 灰出し(乾式)コンベヤ用

・搬送物:焼却後の灰 灰出し(湿式)コンベヤ用

・搬送物:焼却後の灰(水分含) |

焼却後やボイラー後に発生する飛灰を搬送するラインです。飛灰が全体に掛かります。また、添加剤による処理後の飛灰を搬送する場合もあります。 飛灰(一般)コンベヤ用

・搬送物:焼却後の飛灰 飛灰(腐食性含)コンベヤ用

・搬送物: 減温塔などで添加剤による処理を行った直後の飛灰 |

溶融炉によって発生したスラグを搬送するラインです。水がスラグにより強アルカリ性や強酸性に変化することがあります。 溶融スラグコンベヤ用

・搬送物:溶融スラグ |

食品業界

食品業界の多彩なニーズに応えるコンベヤチェーン

精製糖

上白糖搬送バケットエレベータ用コンベヤチェーン

発錆や摩耗による金属粉の発生を抑えたバケットエレベータ用コンベヤチェーン。チェーンの汚れを最小限にした美麗仕様が採用されています。

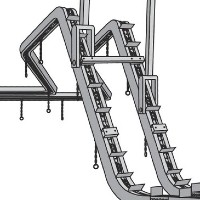

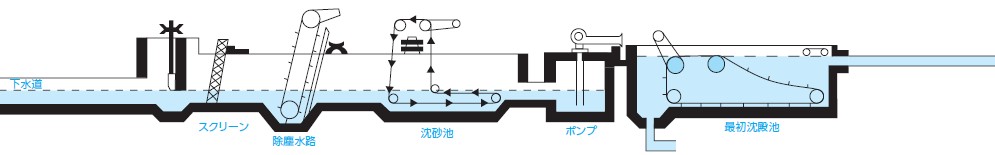

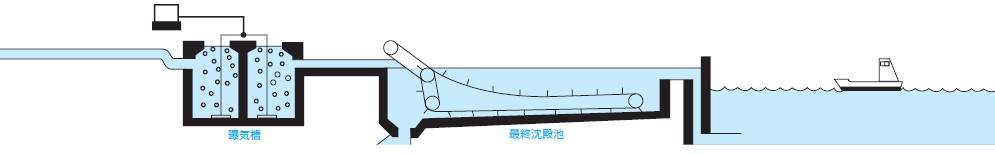

水処理施設

水処理装置系統図

自動車業界

「耐摩耗」「位置決め」「アキュムレート」「大荷重」「シャクリ対策」「長機長」など、様々なニーズに対応したコンベヤチェーン

プレス

車体溶接

塗装

塗装

ドア、ボデー他部品の塗装

・台車牽引用

- ドッグ付コンベヤチェーン

組立

組立

車体搬送、マンコンベヤ

・局所的な大荷重/長機長

→ブシュ~ローラの間の摩耗が大きい

・シャクリの発生

→作業性が低下

- ベアリングローラコンベヤチェーン

・ブシュ~ローラ間に円筒コロを採用

・ブシュ~ローラ間耐摩耗性向上

・転がり摩耗係数1/3により

安定・省エネ・大荷重搬送

長機長、大荷重でも低床(300mm以下)で設置ができるコンベヤチェーンも対応可能です。

検査

検査

シャワーテスタ、最終検査拭上げ(オプション取付)ライン

シャワーテスタ&最終検査ライン

〈ローラ形式 WDR/WDF〉

水がかかる環境とドライ環境、いずれも無給油で使用可能

| ローラ形式 WDR/WDF |

ベアリングローラコンベヤチェーン | 【参考】 RT仕様 (ベースチェーン) |

||

| 無給油耐水仕様 | 標準仕様 | |||

| シャワーテスタ | ○ | ◎ | × | △ |

| 検査ライン | ◎ | △ (水潤滑追加要) |

◎ (水がかからない) |

△ (給油要) |

| ローラ転がり 摩耗係数 |

0.12 | 0.03 | 0.03 | 0.15 |

| 備考 | 水+ドライが無給油で 実現 |

シャワーテスタ用途として 最適 |

水がかかる用途は 不適 |

SUS製耐環境 チェーン |

◎:最適

○:使用可能

△:条件付で使用可能

×:使用不可

チェーンの摩耗伸びを抑えたい

ベーシックモデル

改善STEP1

改善STEP2

ベーシックモデル

改善STEP1

改善STEP2

ローラの摩耗寿命を伸ばしたい

ベーシックモデル

改善STEP1

改善STEP2

改善STEP3

コンベヤチェーン

カズモノ搬送専用

ベーシックモデル

アドバンスモデル

改善STEP3

バラモノ搬送

腐食雰囲気などでのチェーンの摩耗伸びを抑えたい

ベーシックモデル

改善STEP1

強度向上

改善STEP2

改善STEP1α

アドバンスモデル

腐食雰囲気でのローラの摩耗寿命を伸ばしたい

ベーシックモデル

改善STEP1

強度向上

改善STEP2

改善STEP1α

アドバンスモデル

改善STEP3

タフコロ

形番 TUF~

フレーム本体とエンドレスローラから構成され、フレーム本体のセンタープレートに

エンドレスローラを巻きつけています。重量物の移動・移載・搬送に最適です。

- ・スチールローラ形(基本負荷能力14.7kN~1961kN)

スチールローラ形は、センタープレートとローラに焼入れを施したコンパクトで負荷能力の大きな

タフコロです。 - ・プラローラ形(基本負荷能力2.94kN~34.3kN)

プラローラ形はエンジニアリングプラスチック(エンプラ)をローラに使用したタフコロです。スチール製ローラの基本的な特長に、エンプラ製ローラによる機能が付加されています。特に「プラジュニア」は手軽にご使用いただける経済的で軽量な簡易形です。

サイズ

スチールローラ形

TUF-J~TUF200

プラジュニア

TUF-JP

プラローラ形

TUF1P~TUF4P

ダブルローラ形

TUF25W-ESP-TTB・TUF4WP-ESP-TTB

軸付ベアリングローラ

形番 JB□□□-□~

ローラ内部に円筒コロを内蔵した軸付ベアリングローラです。

重量物の移動・移載・搬送に最適です。

- ・重量物の移動・移載・搬送用途で、車輪・ガイドローラなどに最適です。

- ・グリース仕様、ノングリース仕様、耐水仕様、耐熱仕様を品揃えしています。

- ・JBR:Rローラ形

- ・JBF:Fローラ形

- ・JBFF:両フランジ付ローラ

- ・JBTF:5°のテーパ付Fローラ形

- ・JBUR:ウレタンローラ

チェーン仕様

グリース仕様(標準仕様),

ノングリース仕様,

耐水仕様, 耐熱仕様

サイズ

JBR03~JBR36

JBF03~JBF36

軸形式

1形, 2形

ローラ形式

BRローラ, BFローラ,

BFFローラ, BURローラ,

BTFローラ

アタッチメント付ベアリングローラ

形番 AB□□□-□~

ローラ内部に円筒コロを内蔵したアタッチメント付ベアリングローラです。

- ・重量物の移動・移載・搬送用途で、車輪・ガイドローラなどに最適です。

- ・グリース仕様、ノングリース仕様、耐水仕様、耐熱仕様を品揃えしています。

- ・ABR:Rローラ形

- ・ABF:Fローラ形

- ・ABFF:両フランジ付ローラ

- ・ABUR:ウレタンローラ

チェーン仕様

グリース仕様(標準仕様),

ノングリース仕様,

耐水仕様, 耐熱仕様

サイズ

ABR03~ABR36

ABF03~ABF36

ローラ形式

BRローラ, BFローラ

BFFローラ, BURローラ