製品情報 直動機器

つばきの直動機器は、高品質な自社製ネジを使用している電動式のシリンダとジャッキ、当社独自のジップチェーン駆動のジップチェーンアクチュエータをラインアップしています。

ネジ機構とジップチェーン機構のいずれも、製品の持つ特長を最大限に活かし、高速・高頻度の運転や高い精度が求められる運転など、幅広い用途でご使用いただけます。

※ジップチェーン機構とは、2本のチェーンがジッパーのように噛み合うことで、1本の強固な柱状となり「押し・引き」で使用できる当社独自の技術です。

直動機構の種類

ジップチェーン機構

- 高速

- 高頻度

- 高耐久性

- コンパクト

つばきの独自技術「ジップチェーン」を用いた機構です。

コンパクト性に優れ、高タクト運転に求められる高速・高頻度・耐久性を持っています。

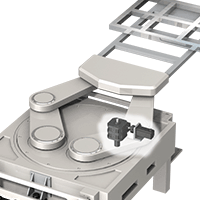

2本のチェーンを噛合せ1本の棒状にすることで、押し引きを可能にしました。

ジッパーのように噛合う様子からジップチェーンと名づけました。

(ジップチェーン機構の特設サイトはこちら)

ボールネジ機構・台形ネジ機構

- 高頻度

- 大許容荷重

- 静粛性

ボールネジ機構

ネジ軸とナットの間に鋼球を入れ、転がり摩擦することで、高効率で動作できるようにした機構です。

台形ネジ機構に比べて高速・高頻度用途に適しているので、生産性が求められる組立ラインなどに適しています。

また、高効率なので駆動源を小形化することができます。

信頼性の高い内製のボールネジを使用しているため、走行寿命の予測も可能です。

ボールネジ1回転当たりの進む距離(リード)が通常のボールネジより長いものをハイリードボールネジと呼び、通常のボールネジと同じ入力回転速度でも高速化が実現できます。

台形ネジ機構

ネジ軸とナットが滑り摩擦することで動作する機構で、メンテナンス用途などの低速・低頻度での運転に向いています。

ボールネジ機構にはないセルフロック性を有しているので、荷重保持が可能です。

また、構造がシンプルなため経済的です。

つばきの直動機器製品群

| 電動シリンダ:パワーシリンダ | スクリュージャッキ: リニパワージャッキ |

ボールネジ昇降ユニット: リニスピードジャッキ |

噛合チェーン式アクチュエータ: ジップチェーンアクチュエータ |

||

|---|---|---|---|---|---|

|

|

|

|

||

| 機構の種類 | ボールネジ 台形ネジ |

ボールネジ ハイリード ボールネジ |

台形ネジ | ボールネジ | ジップチェーン |

| 目的 | 負荷の押し引き | 負荷の押し引き | 負荷の保持 | 負荷の押し引き | 負荷の押し引き |

| 特長 | モータ一体型で簡単配線 クリーンな環境を実現 |

各種ねじタイプを選択可 | 高速・高頻度、低床、長寿命 | 他機構を圧倒する高速・高頻度、 低床、長寿命 |

|

| 推力 | 最大490kN | 4.90kN~980kN | 1.96kN~980kN | 15kN~50kN | 400N~2000N |

| ストローク | 最大2000mm | 最大2000mm | 最大1500mm | 最大2000mm | |

| 速度・運転頻度 | 最大速度:333mm/s 負荷時間率:50%ED※1 |

ネジ軸最大速度: 50~120mm/s※2 許容負荷時間率: 30%ED |

ネジ軸最大速度: 40mm/s 許容負荷時間率: 20%ED |

ネジ軸最大速度:200mm/s 許容負荷時間率:100%ED※3 |

最大速度:1000mm 負荷時間率:100%ED |

| 用途例 |

傾動装置

ストッパ |

テーブル昇降

圧延ロール |

トラバーサの

取出し |

段積・段ばらし

パレットの |

|

- ※1 エコシリーズ サーボタイプの場合

- ※2 ネジタイプによって異なります

- ※3 条件により異なります

直動機器製品一覧

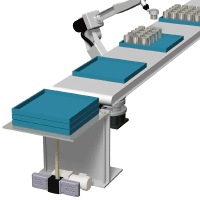

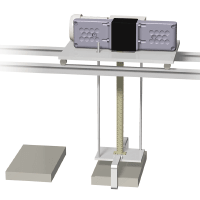

圧倒的な省スペース化を実現したアクチュエータ

ジップチェーンは、2本のチェーンがジッパーのように噛み合い、強固な棒状になることで「押し・引き」の動作を可能にする、当社独自開発のチェーンです。

この技術を採用した全く新しい直動機器が、ジップチェーンアクチュエータです。

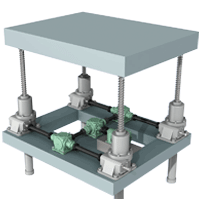

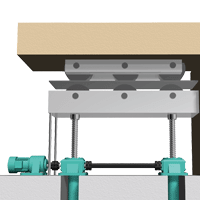

ジップチェーンはコンパクトなケースに収納できるため、従来の直動機器と比較して圧倒的な省スペース化を実現しました。また、高速・高頻度運転に対応し、油圧や空圧シリンダに比べて使用電力量を大幅に削減できます。さらに、高精度な多点停止が可能で、取付方向も自由です。

ジップチェーンアクチュエータ®

形番 ZCA~

今までにない高速・高頻度・低床・長寿命アクチュエータ

- ・コンパクト:

チェーンケースの高さはストロークに対し約1/10と低床なので、狭いスペースでの設置が可能。ギヤモータなどの駆動部と一体化することでさらにコンパクトに。 - ・高速運転:

最大1000mm/sの高速運転を実現。ネジ式や油圧式・空圧式シリンダの速度を圧倒します。 - ・負荷時間率100%ED:

サーボモータを使用すれば、高精度な多点停止や連続運転が可能。 - ・長寿命:

耐摩耗性に優れ、チェーン伸びがないので、期待走行距離4000kmを実現。 - ・据付方向自由:

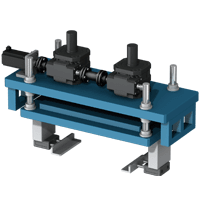

押上・水平・吊下などのお客様のニーズに合った据付方向で自由に設置できます。 - ・豊富なラインナップ:

全サイズでハイポイドモートル付が対応可能です。サーボ用減速機TERVO付はサーボモータとの一体化により、コンパクト構造で高速位置決め運転を実現できます。 - ・最大推力38.2kN/最大ストローク5000mmの中・大形サイズの対応も可能です。

-

エコ&エコ ポイント

【コンパクト】【長寿命】

定格推力 N

400~2000

※モータ無しの場合

昇降機構

ジップチェーン

ストロークmm

300~2000