Q&A 直動機器

お客様から寄せられました「よくある質問」をQ&A形式で掲載しています。質問をクリックして回答へお進みください。

リニパワージャッキ

Q&A内で語句を

| Q1 | リニパワージャッキは環境にやさしいのでしょうか? | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 使用条件や計算基準により異なりますが一般的に油圧式と比較した場合、リニパワージャッキは約3分の1の電力で稼働します。 | |||||||||||||||||||

| Q2 | RoHS指令に対応できますか? | |||||||||||||||||||

| A2 | 一部モータ付を除いて欧州RoHS指令対応は可能ですので、当社へお問い合わせください。 | |||||||||||||||||||

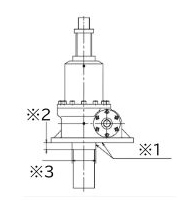

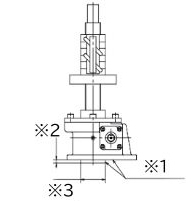

| Q3 | 回り止め仕様とはどういう仕様でしょうか? | |||||||||||||||||||

| A3 | 標準仕様では、軸端が固定されていたり、回転力を受ける機構がある場合、ネジシャフトは回転せずに昇降しますが、ネジシャフトが回転してしまう場合は、昇降しないのでジャッキのネジシャフトが回転しないようにする必要があります。 | |||||||||||||||||||

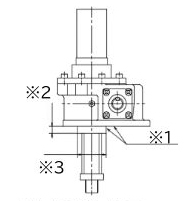

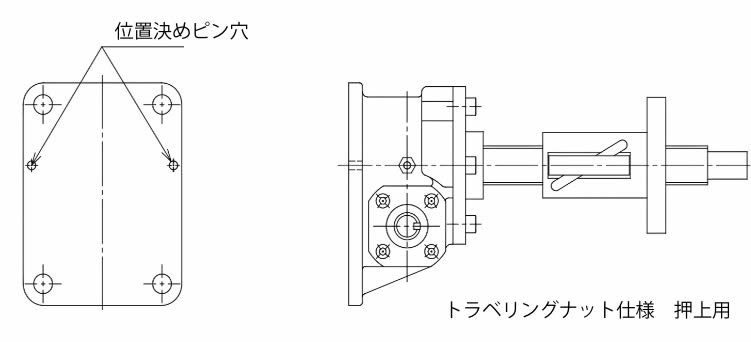

| Q4 | トラベリングナット仕様とはどういう仕様でしょうか? | |||||||||||||||||||

| A4 | 標準仕様、回り止め仕様ではナットを回転させることにより、ネジシャフトが昇降しますが、トラベリングナット仕様は、ネジシャフトを回転させることによりナットを昇降させる機構となります。 | |||||||||||||||||||

| Q5 | 使用環境温度は何度まで対応できますか? | |||||||||||||||||||

| A5 | リニパワージャッキの運転状態でジャッキ表面温度が-15°C~80°Cでまで使用可能です。 | |||||||||||||||||||

| Q6 | リニパワージャッキで屋外仕様は製作可能でしょうか? | |||||||||||||||||||

| A6 | 塗装・シール加工等で屋外対策は可能ですが、直接水がかかる環境では、お客様の方でカバーを設ける等、対策を施してください。 | |||||||||||||||||||

| Q7 | 押付停止はできますか? | |||||||||||||||||||

| A7 | 通常のモータ駆動での押付停止は、押し付け時に衝撃が発生し、故障の原因となります。 | |||||||||||||||||||

| Q8 | トラベリングナット仕様で先端がフリーな状態で使用可能ですか? | |||||||||||||||||||

| A8 | 使用可能です。但し許容座屈荷重・許容入力回転速度が制限されますので、使用上十分にご注意ください。 | |||||||||||||||||||

| Q9 | 2台連動の場合、リニパワージャッキに回り止め仕様は必要ですか? | |||||||||||||||||||

| A9 | 不要です。連動運転の場合、必ずガイドを設けてください。 | |||||||||||||||||||

| Q10 | 水平方向での使用に問題はありませんか? | |||||||||||||||||||

| A10 | 水平方向での使用は可能です。 | |||||||||||||||||||

| Q11 | 連動運転において、リニパワージャッキの据付け時の注意点を教えてください。 | |||||||||||||||||||

| A11 | リニパワージャッキを複数台で使用しますので、複数のジャッキの芯高さ・入力軸高さなどジャッキのレベル出しには十分にご注意ください。 | |||||||||||||||||||

| Q12 | リニパワージャッキの揺動運転は可能ですか? | |||||||||||||||||||

| A12 | 先端部をI型金具にして、クレビス金具・トラ二オン金具(オプション)で取付けることにより揺動運転は可能です。 | |||||||||||||||||||

| Q13 | 両端クレビス支持はどのような場合で使用しますか? | |||||||||||||||||||

| A13 | 両端クレビス支持は揺動運転に最適な据付けです。揺動運転でご使用ください。 | |||||||||||||||||||

| Q14 | JWB(ボールネジタイプ)で負荷時間率30%ED以上で使用したいのですが対応可能ですか? | |||||||||||||||||||

| A14 | お客様の使用環境を十分確認させていただいた上でご提案することは可能です。 | |||||||||||||||||||

| Q15 | 入力軸の片側カットや軸端タップ加工、メッキ処理などは可能ですか? | |||||||||||||||||||

| A15 | 特形品として対応可能です。過去に実績は多数ありますので、当社へお問い合わせください。 | |||||||||||||||||||

| Q16 | 入力軸のバックラッシは、どれくらいありますか? | |||||||||||||||||||

| A16 | ネジ単体のガタ、ウォームギヤのガタが入力軸のバックラッシとなります。 | |||||||||||||||||||

| Q17 | ジャッキの入力軸にモータやギヤモートルを取り付けた状態で出荷可能ですか? | |||||||||||||||||||

| A17 | JWM(台形ネジタイプ)・JWB(ボールネジタイプ)・JWH(ハイリードボールネジタイプ)でオプションとしてモータ・ギヤモートル付きの製作は可能です。 | |||||||||||||||||||

| Q18 | ジャッキ入力軸を手動ハンドルで回すことは可能ですか? | |||||||||||||||||||

| A18 | オプションで手動ハンドルを用意しています。セルフロックが効く台形ネジタイプで使用することができます。 | |||||||||||||||||||

| Q19 | サーボモータを取り付けて昇降させたいのですが、そのときの注意事項はありますか? | |||||||||||||||||||

| A19 | サーボモータは高速・高頻度で動かす場合に適しています。 | |||||||||||||||||||

| Q20 | オイル潤滑仕様は製作可能ですか? | |||||||||||||||||||

| A20 | 特形品として製作可能です。 | |||||||||||||||||||

| Q21 | 減速部のグリースはどれくらいの間隔で交換する必要がありますか? | |||||||||||||||||||

| A21 | 枠番025以上は、1日の使用頻度によって給脂サイクルの目安を設けています。

| |||||||||||||||||||

| Q22 | 減速部のグリースの交換方法を教えてください。 | |||||||||||||||||||

| A22 | 六角穴付きプラグを外して、グリースニップルから入れたグリースが取り外した六角穴付きプラグの穴からあふれ出るまでグリースを給脂してください。 | |||||||||||||||||||

| Q23 | JWM(台形ネジタイプ)の場合、セルフロックは期待できますか? | |||||||||||||||||||

| A23 | JWM(台形ネジタイプ)は計算上セルフロックを有していますが、振動・衝撃などによりセルフロックが効かない場合もあります。 | |||||||||||||||||||

| Q24 | ストローク範囲を超えるとどうなりますか? | |||||||||||||||||||

| A24 | 標準仕様の場合、JWB(ボールネジタイプ)・JWH(ハイリードボールネジタイプ)にはネジにストッパーが付いていますので、抜け落ちことはありませんが、JWM(台形ネジタイプ)ではネジが抜け落ちる場合があります。 | |||||||||||||||||||

| Q25 | JWH(ハイリードボールネジタイプ)のメリットを教えてください。 | |||||||||||||||||||

| A25 | ネジリードが通常のJWB(ボールネジタイプ)より大きいので、高速運転に適しています。 | |||||||||||||||||||

| Q26 | リニパワージャッキのネジは横荷重を受けられますか? | |||||||||||||||||||

| A26 | JWB(ボールネジタイプ)では横荷重を受けることはできませんが、JWM(台形ネジタイプ)では、静止時に限りある程度横荷重に耐えられるようになっています。 | |||||||||||||||||||

| Q27 | JWH(ハイリードボールネジタイプ)のジャバラはどうして特殊仕様なのですか? | |||||||||||||||||||

| A27 | JWH(ハイリードボールネジタイプ)は、高速運転用ですので、ジャバラ内の空気を素早く逃がすための空気穴を設ける必要があり、特殊仕様としています。 | |||||||||||||||||||

| Q28 | トラベリングナット仕様の標準的なジャバラは無いのですか? | |||||||||||||||||||

| A28 | トラベリングナット仕様はネジ軸上をナットが移動する構造ですので、移動するストロークによってジャバラの長さ、またナットの取付方向によってジャバラの径が決まります。 | |||||||||||||||||||

| Q29 | ジャバラ交換時にテーブル形先端金具が外れません。どうしたら良いでしょうか? | |||||||||||||||||||

| A29 | テーブル形先端金具は、ネジ緩み止め接着剤を塗布して、ネジ軸端にねじ込んでいます。 | |||||||||||||||||||

| Q30 | ジャッキを据付しやすくするため、例えばジャッキ据付面にインローを設けることは可能ですか? | |||||||||||||||||||

| A30 | インロー付も製作可能です。インローは公差を設けた凸寸法部で、装置の分解・組立が必要な場合の再現性や据付精度の向上に適しています。インロー径や寸法公差は、お客様の要求にも対応可能ですので、お問い合わせください。 | |||||||||||||||||||