トラブルシューティング タイミングベルト・タイミングプーリの異常とその手当

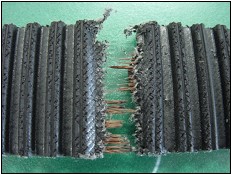

| 1 | ベルトの早期切断 |

|---|---|

| 2 | ベルト歯の摩耗 |

| 3 | ベルトの歯飛び |

| 4 | ベルト歯の剪断破壊 |

| 5 | ベルト側面のムシレおよび摩耗 |

| 6 | ベルト歯面の縦列キズ |

| 7 | ベルトの部分的切断 |

| 8 | ベルトの収縮 |

| 9 | ベルトのみかけ上の伸び |

| 10 | ベルト背面のゴムの粘りあるいは軟化 |

| 11 | ベルト背面ゴムの摩耗 |

| 12 | ベルト背面ゴムの亀裂 |

| 13 | プーリ歯の摩耗 |

| 14 | 騒音 |

| 1 |

|---|

| 原因1 | オーバロード | 手当法 | 被動体の慣性、原動機、使用条件などを点検する。 |

|---|---|---|---|

| 原因2 | ショックロード | 手当法 | ベルトのサイズアップ、衝撃緩和機構を設ける。 |

| 原因3 | ベルトの折曲げ | 手当法 | ベルトの運搬、保管、取付けに注意する。 |

| 原因4 | プーリ径が過小 | 手当法 | プーリ歯数を許容最小歯数以上とする。 |

| 2 |

|---|

| 原因1 | オーバロード | 手当法 | 設計を変更する。 |

|---|---|---|---|

| 原因2 | 取付張力の過大 | 手当法 | 取付張力を調節する。 |

| 原因3 | 取付張力の不足 | 手当法 | 取付張力を調節する。 |

| 原因4 | プーリの歯形および歯部寸法不良 | 手当法 | 正しい歯形および寸法のプーリと交換する。 |

| 原因5 | 粉塵雰囲気における使用 | 手当法 | 雰囲気を改善するか、カバーをつける。 |

| 3 | ベルトの歯飛び |

|---|

| 原因1 | ショックロード | 手当法 | ベルトをサイズアップする。 |

|---|---|---|---|

| 原因2 | ベルトの取付張力の不足 | 手当法 | 取付張力を適正にする。 |

| 原因3 | かみ合い歯数の不足 | 手当法 | プーリ歯数を大きくするか、アイドラによりかみ合い歯数を多くする。 |

| 原因4 | ベルトをかける架台の剛性不足 | 手当法 | 剛性を持った架台とする。 |

| 4 |

|---|

| 原因1 | 現象2、3の末期現象 | 手当法 | 現象2、3の対策と同じ。 |

|---|

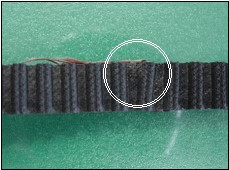

| 5 |

|---|

| 原因1 | 軸の平行度不良 | 手当法 | 平行度を正す。 |

|---|---|---|---|

| 原因2 | プーリの整列不良 | 手当法 | 整列を正す。 |

| 原因3 | ベルトをかける架台の剛性不足 | 手当法 | 剛性を持った架台とする。 |

| 原因4 | フランジの曲り | 手当法 | 良品フランジと取替えるか、修正する。 |

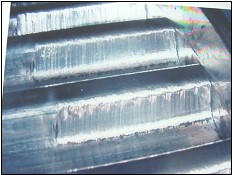

| 6 |

|---|

| 原因1 | プーリ端部へのベルトのはみ出し走行 | 手当法 | プーリの整列、軸の平行度を正す。 |

|---|---|---|---|

| 原因2 | ベルトのフランジへの乗上げ | 手当法 | 適正な取付張力を与える。 |

| 7 |

|---|

| 原因1 | 異物のかみ込み | 手当法 | 環境を改善するか、カバーを付ける。 |

|---|---|---|---|

| 原因2 | ベルトのフランジへの乗上げ | 手当法 | ベルトの取付張力を適正にし、軸の平行度を正確にする。 |

| 8 |

|---|

| 原因1 | 油分や水分による膨潤 | 手当法 | 油や水が掛からない雰囲気に改善するか、カバーを付ける。 |

|---|

| 9 | ベルトのみかけ上の伸び |

|---|

| 原因1 | 軸の移動による軸同士の接近 | 手当法 | 軸受を強固に取付け、衝撃の多い場合はストッパーで軸受の移動を防止する。 |

|---|

| 10 |

|---|

| 原因1 | 背面押しアイドラのスリップ | 手当法 | 取付張力を適正にする。アイドラの慣性を小さくする。 |

|---|---|---|---|

| 原因2 | オイルの付着 | 手当法 | オイルが掛からない雰囲気に改善するか、カバーを付ける。 |

| 原因3 | 高温雰囲気中での使用 | 手当法 | 雰囲気温度を下げる。 |

| 11 | ベルト背面ゴムの摩耗 |

|---|

| 原因1 | 背面押しアイドラ軸の平行度の不良 | 手当法 | アイドラ軸の平行度を正す。 |

|---|---|---|---|

| 原因2 | 背面押しアイドラの回転不良 | 手当法 | アイドラの回転を良くする。 |

| 12 |

|---|

| 原因1 | プーリ径が過小 | 手当法 | プーリ径を大きくする。 |

|---|---|---|---|

| 原因2 | 低温雰囲気中での使用 | 手当法 | 雰囲気温度を改善する。 |

| 13 |

|---|

| 原因1 | プーリ材質の不適切 | 手当法 | 硬度の高い材料、歯面硬化あるいは表面処理によりプーリに耐摩耗性を持たせる。 |

|---|---|---|---|

| 原因2 | 粉塵雰囲気における使用 | 手当法 | 雰囲気を改善するか、カバーを付ける。 |

| 原因3 | 取付張力の過大 | 手当法 | 取付張力を調節する。 |

| 14 | 騒音 |

|---|

| 原因1 | 取付張力の過大 | 手当法 | 取付張力を適正にする。 |

|---|---|---|---|

| 原因2 | オーバロード | 手当法 | ベルトをサイズアップする。 |

| 原因3 | 軸の平行度、プーリの整列不良 | 手当法 | 軸の平行度、プーリの整列を正す。 |