Q&A カップリング

お客様から寄せられました「よくある質問」をQ&A形式で掲載しています。質問をクリックして回答へお進みください。

Q&A内で語句を

エクトフレックスカップリング - 基本・取扱編 ※NESシリーズは対象外です。

エクトフレックスカップリング - 設計・仕様編 ※NESシリーズは対象外です。

ATRAFLEXカップリングAFTシリーズ - 特長

| Q21 | なぜメンテナンス工数で、大幅に時間削減をできるのでしょうか? |

|---|---|

| Q22 | 給脂は必要なのでしょうか? |

| Q23 | 他社製品には基準トルクと伝動能力表がありますが、ATRAFLEXRカップリングには「許容トルク」のみ記載されているのはなぜでしょうか? |

| Q24 | 使用温度範囲を教えてください。 |

| Q25 | インサートは種類があるのでしょうか? |

| Q26 | 各インサートの特長を教えてください。 |

ATRAFLEXカップリングAFTシリーズ - 注意点

| Q27 | 使用環境の注意点を教えてください。 |

|---|---|

| Q28 | 絶縁性はあるのでしょうか? |

| Q29 | 腐食しやすい雰囲気で使用したいのですが、防錆対策はあるのでしょうか? |

| Q30 | 切削油や潤滑油の影響はあるのでしょうか? |

| Q31 | 耐薬品性はあるのでしょうか? |

ATRAFLEXカップリングAFTシリーズ - 特殊

| Q32 | 軸間距離が長い場合に使用可能でしょうか? |

|---|---|

| Q33 | 軸方向に長いハブを製作は可能でしょうか? |

| Q34 | 軸径が標準ハブの最大軸穴径を超えてしまっています。どのようにすれば使用できるのでしょうか? |

| Q35 | キー締結以外の締結方法があるのでしょうか? |

| Q36 | 連結したい軸が天地方向にあるのですが、使用可能でしょうか? |

| Q37 | 昇降装置での使用は可能でしょうか? |

ATRAFLEXカップリングAFTシリーズ - 点検

| Q38 | 点検時期を教えてください。 |

|---|---|

| Q39 | バックラッシ量について教えてください。 |

| Q40 | 部品単体での購入は可能でしょうか? |

ローラチェーンカップリング

| Q1 | なぜ、無給油かつノンバックラッシで使用できるのでしょうか? | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 |

エクトフレックスカップリングは、リーマボルトとUナットとの締め付けによるディスクの摩擦力によって動力を伝達します。したがって、ガタや摺動が無く、給油の必要もありません。

|

|||||||||||||||||||||

| Q2 | 許容トルクを上回るトルクがかかると、どうなりますか? | |||||||||||||||||||||

| A2 |

許容トルクは、リーマボルトとUナットの締め付けによるディスクとの摩擦力により決定されます。許容トルク以上の負荷がかかるとスリップが発生し、カップリングが破損する原因になります。なお、締結方法により、許容トルクが低下することがありますので、詳しくはカタログをご参照ください。 |

|||||||||||||||||||||

| Q3 | エクトフレックスカップリングの使用可能な周囲温度は何度までですか? | |||||||||||||||||||||

| A3 |

耐熱温度:200℃ |

|||||||||||||||||||||

| Q4 | 防錆対策として、ステンレス仕様や無電解ニッケルメッキ仕様の製作はできますか? | |||||||||||||||||||||

| A4 |

主にクリーンルーム用途での簡易防錆として、無電解ニッケルメッキ仕様を標準化しています。また、ステンレス仕様も製作していますので、お気軽に当社までご相談ください。 質問へ戻る |

|||||||||||||||||||||

| Q5 | エクトフレックスカップリングに塗装することはできますか? | |||||||||||||||||||||

| A5 |

エクトフレックスカップリングに塗装を施すと、膜厚により外径寸法が変わるため、心出しの妨げとなり、おすすめできません。どうしても塗装が必要な場合は、当社までお問合せください。 質問へ戻る |

|||||||||||||||||||||

| Q6 | トルクレンチを使用しないでUナットを締め付けると、どうなりますか? | |||||||||||||||||||||

| A6 |

許容トルクは規定の締付トルクでUナットを締め付けた場合の値ですので、トルクレンチを用いない締め付けは、締め付け不足によるスリップ、締め付け過大による部品の変形など事故の原因となります。締め付けの際は必ずトルクレンチを使用して、規定の締付トルクで締め付けてください。 質問へ戻る |

|||||||||||||||||||||

| Q7 | 組み付けの際、リーマボルトを入れる方向は決まっていますか? | |||||||||||||||||||||

| A7 |

リーマボルトはどちらから入れても構いません。ただし、ワッシャA、Bは方向が決まっていますので、取扱説明書やカタログの記載内容どおりに組み立てるようにしてください。 ホームページに組立方法を解説した3D動画も掲載しておりますので、ご参照ください。 |

|||||||||||||||||||||

| Q8 | カップリング組付け後にディスクが軸方向にペコペコ動くのですが、大丈夫でしょうか? | |||||||||||||||||||||

| A8 |

Uナットを締め付ける際、カップリングにスラスト荷重がかかっていると、ディスクが軸方向にペコペコと動く現象が起こります。この現象を当社では"ペッコン現象"と称しており、ディスクに余計な応力が掛かっているため、そのままの状態でのご使用はお勧めできません。ペッコン現象が起こった場合は、一旦Uナットを緩め、カップリングにスラスト荷重が掛からない状態で再度組み付けすれば解消します。 質問へ戻る |

|||||||||||||||||||||

| Q9 | リーマボルトは市販品との互換性はありますか? | |||||||||||||||||||||

| A9 |

エクトフレックスカップリング用リーマボルトは、専用特殊設計品のため、市販品との互換性はありません。リーマボルトが必要な場合は、販売店経由にて、当社までご発注ください。 質問へ戻る |

|||||||||||||||||||||

| Q10 | 部品の互換性はありますか? | |||||||||||||||||||||

| A10 |

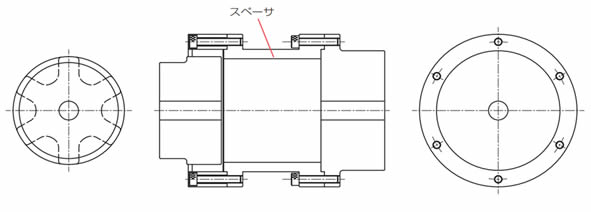

シングルタイプ、スペーサタイプ、ロングスペーサタイプで使用しているハブ、ディスク、ボルトは共通で互換性があります。 質問へ戻る |

|||||||||||||||||||||

| Q11 | シングルタイプの平行偏心の許容値はいくらですか? | |||||||||||||||||||||

| A11 |

シングルタイプは偏角だけを吸収し、平行偏心は吸収しません。NC工作機、サーボモータとの精密心出しができる取り付けに限り推奨します。一般的にはスペーサタイプをご使用ください。 質問へ戻る |

|||||||||||||||||||||

| Q12 | 高速回転で使用する場合に、動バランス調整は必要ですか? | |||||||||||||||||||||

| A12 |

振動や音の発生が問題となる場合、装置組立後にバランス調整が必要な場合があります。バランス等級と回転速度を指定していただければ、当社にて調整の可否を検討させていただきます。 質問へ戻る |

|||||||||||||||||||||

| Q13 | ロングスペーサタイプの選定で注意することは何でしょうか? | |||||||||||||||||||||

| A13 |

ロングスペーサタイプを高速で使用される場合、危険速度を避けるため、回転速度をチェックする必要があります。選定の際には、各形番におけるハブ端面間距離(J寸法)、回転速度が限界内にあるか、カタログで確認願います。詳しくは当社までお問合せください。 質問へ戻る |

|||||||||||||||||||||

| Q14 | ロングスペーサタイプはどのくらいの長さまで製作できますか? | |||||||||||||||||||||

| A14 |

エクトフレックスカップリング・ロングスペーサタイプは、最大でハブ端面間距離6,000mmまで製作可能です。(NEH41W以下のサイズ) |

|||||||||||||||||||||

| Q15 | 立て形の取付レイアウトで使用できますか? | |||||||||||||||||||||

| A15 |

標準スペーサタイプ、シングルタイプであれば問題ありません。ロングスペーサタイプは、ハブ端面間距離(J寸法)が下表を超える場合、自重を受けるための特殊構造になりますので、当社までご相談ください。

|

|||||||||||||||||||||

| Q16 | ギヤカップリング対応のGタイプとはどういうものですか? | |||||||||||||||||||||

| A16 |

ギヤカップリングと全長、ハブ長さを同一にすることで、そのまま取り替え可能です。エクトフレックスカップリングに交換することで給油が不要になり、メンテナンス工数を削減できます。(受注生産品)

|

|||||||||||||||||||||

| Q17 | 「パワーロック」仕様はELタイプが標準ですが、その他のシリーズのパワーロックで取り付けできますか? | |||||||||||||||||||||

| A17 |

可能です。ただし、パワーロックの発生面圧に耐えられるかどうか、ハブのボス径のチェックが必要です。一般的には広範囲な公差軸に対応可能なKEシリーズや、小径ボス用のTFシリーズをお奨めします。 質問へ戻る |

|||||||||||||||||||||

| Q18 | 「パワーロック」仕様を中空軸に使用できますか? | |||||||||||||||||||||

| A18 |

中空軸の材質強度及び中空軸内径により、使用可否の検討が必要になりますので、中空軸にパワーロック仕様をご使用になる場合には、当社までご相談ください。 質問へ戻る |

|||||||||||||||||||||

| Q19 | 左右のキー溝の位相を合わせることはできますか? | |||||||||||||||||||||

| A19 |

キー溝の位相を正確に合わせる必要がある場合は、ご用命時に「キー溝位相合わせ仕様」とご指示ください。この場合、最大位相差は±2度にて製作いたします。さらに高精度の位相合わせが必要な場合は、パワーロック仕様を推奨いたします。 質問へ戻る |

|||||||||||||||||||||

| Q20 | テーパ軸穴加工はできますか? | |||||||||||||||||||||

| A20 |

サーボモータ軸用のΦ16(1/10 テーパ)もしくはΦ11(1/10 テーパ)であれば製作可能です。それ以外の寸法につきましては、テーパゲージをご支給いただければ製作いたします。 質問へ戻る |

|||||||||||||||||||||

| Q21 | なぜメンテナンス工数で、大幅に時間削減をできるのでしょうか? | |||||||||||||||||||||

| A21 |

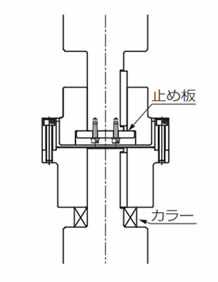

本製品は、ドライブリンクを外してインサートの変形を定期的に点検、交換するだけで、メンテナンスを実施できます。駆動機または被動機を移動させずにインサート交換が可能で、ハブの交換や再度の心出しも不要です。以上のことから、メンテナンス工数の大幅な削減に寄与できます。 質問へ戻る |

|||||||||||||||||||||

| Q22 | 給脂は必要なのでしょうか? | |||||||||||||||||||||

| A22 |

給脂不要です。ATRAFLEXカップリングは金属同士の摺動がないため、給脂せず使用いただけます。 質問へ戻る |

|||||||||||||||||||||

| Q23 | 他社製品には基準トルクと伝動能力表がありますが、ATRAFLEXRカップリングには「許容トルク」 のみ記載されているのはなぜでしょうか? | |||||||||||||||||||||

| A23 |

ギヤカップリングは回転速度が増加するほど許容トルクは減少します。一方で、ATRAFLEXは許容回転速度内において一定の許容トルクでの伝達が可能です。 質問へ戻る |

|||||||||||||||||||||

| Q24 | 使用温度範囲を教えてください。 | |||||||||||||||||||||

| A24 |

標準、高トルク、高減衰タイプは-30~120℃です。耐熱タイプのインサートは-5~175℃になります。 質問へ戻る |

|||||||||||||||||||||

| Q25 | インサートは種類があるのでしょうか? | |||||||||||||||||||||

| A25 |

インサートは4タイプあり、標準(イエロー)、耐熱(レッド)、高トルク(オレンジ)、高減衰(グリーン)と、特長によって色が異なります。 質問へ戻る |

|||||||||||||||||||||

| Q26 | 各インサートの特長を教えてください。 | |||||||||||||||||||||

| A26 |

耐熱タイプは、他のインサートに比べ使用温度範囲(-5~175℃)が高くなります。 高トルクタイプは、標準タイプより許容トルクを高く設定しています。標準タイプでトルクが少し足りない場合、高トルクタイプを使用いただくことで、サイズアップすることなくご使用いただけます。 高減衰タイプは、急加速や急停止、慣性が大きな用途で振動が発生した場合に、振動を素早く抑える必要がある用途に適しております。 質問へ戻る |

|||||||||||||||||||||

| Q27 | 使用環境の注意点を教えてください。 | |||||||||||||||||||||

| A27 |

腐食性の液体やガスのある場所、引火性・爆発性のある場所、及び屋外でのご使用は避けてください。 インサートは、空気中の水分、大気ガス、熱、紫外線などの影響を受け、時間経過とともに少しずつ劣化が進行しますので、なるべく風通しの良い、ほこりや湿気の少ない所で使用してください。 質問へ戻る |

|||||||||||||||||||||

| Q28 | 絶縁性はあるのでしょうか? | |||||||||||||||||||||

| A28 |

絶縁性の保証はできません。インサートは電気を通しませんが、表面が濡れていたりすると、そこから通電しますので、ご注意下さい。なお、ミスアライメントが大きい際にハブ同士が接触し、そこから通電します。従いまして、心出し精度を高めていただければ、絶縁性を確保できます。 絶縁仕様が必要な場合は、特殊仕様として検討可能ですので、詳しくは当社までお問い合わせください。 質問へ戻る |

|||||||||||||||||||||

| Q29 | 腐食しやすい雰囲気で使用したいのですが、防錆対策はあるのでしょうか? | |||||||||||||||||||||

| A29 |

防錆対策として、無電解ニッケルメッキ仕様を標準化しています。ステンレス仕様も製作可能です。 質問へ戻る |

|||||||||||||||||||||

| Q30 | 切削油や潤滑油の影響はあるのでしょうか? | |||||||||||||||||||||

| A30 |

インサートの素材はエーテル系ポリウレタンを採用しています。加水分解は引き起こしにくいですですが、耐油性についてはエステル系より劣ります。 質問へ戻る |

|||||||||||||||||||||

| Q31 | 耐薬品性はあるのでしょうか? | |||||||||||||||||||||

| A31 |

耐薬品性も有します。詳しくは当社までお問い合わせください。 質問へ戻る |

|||||||||||||||||||||

| Q32 | 軸間距離が長い場合に使用可能でしょうか? | |||||||||||||||||||||

| A32 |

スペーサタイプでの検討が可能です。軸端間距離をご教示ください。  質問へ戻る

質問へ戻る

|

|||||||||||||||||||||

| Q33 | 軸方向に長いハブを製作は可能でしょうか? | |||||||||||||||||||||

| A33 |

延長ハブ(Lハブ)も製作可能です。キー面圧を下げることも可能です。 質問へ戻る |

|||||||||||||||||||||

| Q34 | 軸径が標準ハブの最大軸穴径を超えてしまっています。どのようにすれば使用できるのでしょうか? | |||||||||||||||||||||

| A34 |

ボス径を大きくした拡大ハブ(Kハブ)も製作可能です。拡大ハブを採用することでサイズアップすることなく、軸穴径を大きくすることができます。 質問へ戻る |

|||||||||||||||||||||

| Q35 | キー締結以外の締結方法があるのでしょうか? | |||||||||||||||||||||

| A35 |

当社パワーロック締結が可能です。KE、AS、TF、ELシリーズなど使用できます。 質問へ戻る |

|||||||||||||||||||||

| Q36 | 連結したい軸が天地方向にあるのですが、使用可能でしょうか? | |||||||||||||||||||||

| A36 |

標準品でも立形取付可能です。ただし、落下防止対策としてハブの自重を受ける機構を設けてください。  質問へ戻る

質問へ戻る

|

|||||||||||||||||||||

| Q37 | 昇降装置での使用は可能でしょうか? | |||||||||||||||||||||

| A37 |

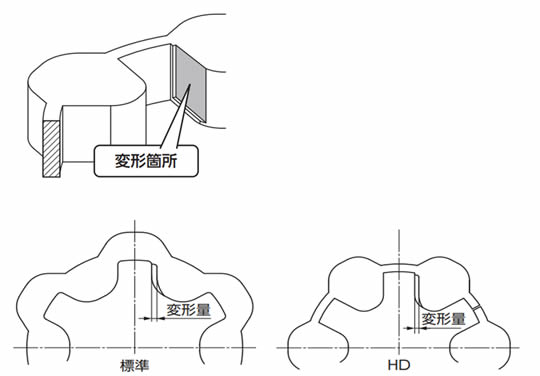

使用可能です。ただし、インサートの変形に十分注意してご使用ください。インサートが変形しきった場合、ドライブリングとフレックスハブは互いに接触していないため、空転します。空転により装置の落下などが考えられる箇所で使用される場合は、必ず落下防止の措置を講じてください。また、半年に一度以上は点検し、規定の変形量に達していれば交換してください。 質問へ戻る |

|||||||||||||||||||||

| Q38 | 点検時期を教えてください。 | |||||||||||||||||||||

| A38 |

実際の運転に入って1~2時間後に、偏角と偏心を再チェックしてください。また、定期的(例えば半年~1年ごと)に部品の異常やインサートの変形を確認してください。インサートは消耗品です、定期的な交換が必要です。 なおインサートの交換目安は、変形量がAFT00は1.2mm、AFT01は1.2mm、AFT02は2.5mm、AFT03は3.8mm、AFT04は5.0mm、AFT05は6.3mm、AFT06は7.6mm、AFT07は8.8mm、これら変形量を確認した際はインサートの交換を実施下さい。  質問へ戻る

質問へ戻る

|

|||||||||||||||||||||

| Q39 | バックラッシ量について教えてください。 | |||||||||||||||||||||

| A39 |

サイズによってバックラッシ量は変わります。AFT00は4.4°、AFT01は2.4°、AFT02は2.0°、AFT03は1.6°、AFT04は3.6°、AFT05は1.6°、AFT06は1.8°、AFT07は1.4°になります。 なおバックラッシ量は計算値であり、保証値ではありません。ミスアライメント量によって異なります。 質問へ戻る |

|||||||||||||||||||||

| Q40 | 部品単体での購入は可能でしょうか? | |||||||||||||||||||||

| A40 |

部品単体での購入は、全部品可能です。 質問へ戻る |

|||||||||||||||||||||

| Q41 | ローラチェーンカップリングに刻印されているCR5016-J等の「J」はどういう意味ですか? | |||||||||||||||||||||

| A41 |

ローラチェーンカップリングは本体とケースから構成されています。いずれも単独で販売できるよう、品名の末尾に本体の場合は「H」を、ケースの場合は「K」をつけてそれぞれの品名としていますが、製品名とは別にJIS規格準拠の意味を示す「J」を本体・ケースともに刻印しています。 |

|||||||||||||||||||||

| Q42 | ローラチェーンカップリングの部品は購入できますか? | |||||||||||||||||||||

| A42 |

以下の部品について部品単体で販売しています。

|

|||||||||||||||||||||

| Q43 | ローラチェーンカップリングのチェーンにつばきRSローラチェーンの標準品は使えますか? | |||||||||||||||||||||

| A43 |

カップリング専用チェーンは2列のRSローラチェーンがベースになっていますので、使用は可能です。ただし、専用ローラチェーンは継手ピン1本を抜き差しすることでチェーンの着脱が可能になっています。2列の標準ローラチェーンを使うと、継手リンクでの連結になりますので、組み付け性が少し劣るため、専用ローラチェーンの使用を推奨します。なお、形番は以下のような意味になっています。

|

|||||||||||||||||||||

| Q44 | 継手ピンを止めるのはクリップですか、割ピンですか? | |||||||||||||||||||||

| A44 |

つばきRSローラチェーンがベースとなっていますので、RSローラチェーンの継手リンクと同様です。 |

|||||||||||||||||||||

| Q45 | ケース用オイルシールの市販品を教えてください。 | |||||||||||||||||||||

| A45 |

オイルシールは専用部品ですので、市販品はありません。 質問へ戻る |

|||||||||||||||||||||

| Q46 | つばきのチェーンカップリング本体に他社製のケースは取付できますか? また、その逆は可能ですか? |

|||||||||||||||||||||

| A46 |

各社独自の設計になっています。微妙に寸法が異なりますので取付は不可です。 質問へ戻る |

|||||||||||||||||||||

| Q47 | 専用グリースは販売していますか? | |||||||||||||||||||||

| A47 |

専用のグリースは販売しておりませんので、市販品をご利用ください。推奨品は以下のとおりです。

* 上表に記載の商品名は各社の商標または登録商標です。 ステンレスシリーズの特殊用途における推奨グリースは以下のとおりです。

■食品グリース |

|||||||||||||||||||||

| Q48 | オイルシールは片側だけで問題ないのでしょうか? | |||||||||||||||||||||

| A48 |

片側はしまりばめになっており、オイルシール側はミスアライメントを吸収しつつグリースを漏れにくくする構造となっています。 質問へ戻る |

|||||||||||||||||||||