技術資料 トップチェーン 選定

選定手順や注意事項等をご覧になりたい方は下記へお進みください。

製品シリーズの絞り込みや仮選定をご希望の方は

こちらをクリックしてください。

使用条件が決まっており詳細な選定をご希望の方は

こちらをクリックしてください。

スナップカバーチェーンの選定

1-1. チェーンサイズの決定

1-1-1. 許容負荷の確認

1リンク当たりにかかる負荷が表1の許容負荷以内かどうか確認ください。

1-1-2. チェーンに作用する張力の計算

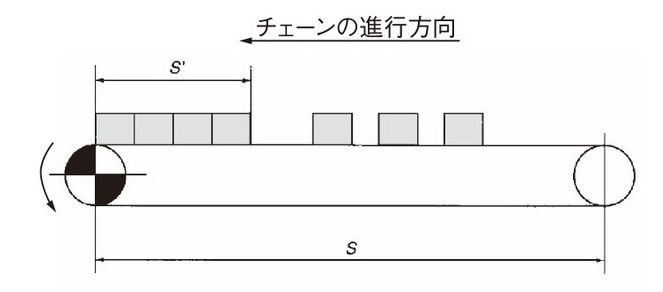

- F = チェーンに作用する最大張力kN{kgf}

- m1 = 搬送物質量(kg/m)

- m2 = チェーン概略質量(kg/m)

- S = 搬送距離(スプロケット中心距離)(m)

- S' = 搬送物が滑ってたまっている長さ(m)

- μ1 = チェーンとレールの摩擦係数[搬送側](表2参照)

- μ2 = チェーンとレールの摩擦係数[戻り側](表3参照)

- μ3 = 搬送物とチェーンの摩擦係数(表4参照)

- P = 所要動力(kW)

- V = チェーン速度(m/min)

- K = 速度係数(表5参照)

- η注) = 駆動部の伝達機械効率

- G = 重力加速度9.80665m/s2

注)伝達機械効率は、使用される駆動装置をご確認ください。

表2. チェーンとレールとの転がり摩擦係数(μ1)

| 潤滑なし | 潤滑有 |

|---|---|

| 0.21 | 0.14 |

表4. 搬送物とチェーン(プラスチックカバー)の動摩擦係数(μ3)

| 搬送物の材質 | 樹脂カバー材質 |

|---|---|

| 普通仕様 導電仕様 |

|

| スチール缶 アルミ缶 |

0.25 |

| 紙パック | 0.3 |

| ガラスビン | 0.22 |

| プラ容器 | 0.25 |

| 工業製品(金属製) | 0.25 |

注)潤滑なしの場合

表1. スナップカバーチェーンの許容負荷

| 仕様 | 許容負荷 kN{kgf}/1リンク | |||||

|---|---|---|---|---|---|---|

| RF06B-SC | RS40-SC | RS50-SC | RS60-SC | RS80-SC | RS100-SC | |

| 普通仕様 NP仕様 ラムダ仕様 |

0.03 {3} |

0.05 {5} |

0.07 {7} |

0.10 {10} |

0.15 {15} |

0.25 {25} |

| SS仕様 | 0.03 {3} |

0.05 {5} |

0.06 {6} |

0.09 {9} |

0.15 {15} |

0.25 {25} |

表3. チェーン(プラスチックカバー)とレールの摩擦係数(μ2)

| 樹脂カバー材質 | レール材質 | |

|---|---|---|

| ステンレス・スチール | 超高分子量 ポリエチレン |

|

| 普通仕様 導電仕様 |

0.25 | 0.25 |

注)潤滑なしの場合

表5. 速度係数(K)

| チェーン速度 m/min | 速度係数 K |

|---|---|

| 15以下 | 1 |

| 15 ~ 30 | 1.2 |

| 30 ~ 50 | 1.4 |

| 50 ~ 60 | 1.6 |

[計算式]

・SI単位(kN)

F = (m1 + m2) S・μ1 + 1.1m2・S・μ2 + m1・S'・μ3 ・ G 1000

・重力単位(kgf)

F = (m1 + m2) S・μ1 + 1.1m2・S・μ2 + m1・S'・μ3[使用可否の確認]

チェーンに作用する最大張力(F)に表5速度係数(K)を乗じ、次式を満足するか確認します。

一条使いの場合

F × K ≦ チェーンの最大許容張力

二条使いの場合

0.6F × K ≦ チェーンの最大許容張力

1-2. 所要動力の計算

・SI単位(kN)

P = F・V 60 × η

・重力単位(kgf)

P = F・V 6120 × η