技術資料 大形コンベヤチェーン 選定

2. コンベヤ形式の決定

| コンベヤ基本形式 | 搬送物 | |||

|---|---|---|---|---|

| かずもの | チェーン形式 | ばらもの | チェーン形式 | |

| 搬送物を載荷する形式 | ・スラットコンベヤ

|

RF- [BR/BF] RF-(NB) RF RF-[DBR/DBF] |

・エプロン/パンコンベヤ

|

RF RF-(KG/KA) |

| ・プッシャコンベヤ・トウコンベヤ ジェットコースタ

|

RF RF-(NB) NF RF-<SR> |

|||

・フリーフローコンベヤ

|

RF-[VR] RF-<SR> RF-<TR> |

|||

・プレーンチェーンコンベヤ

|

RF NF RF-(DL) |

|||

| 搬送物を懸垂する形式 | ・トロリコンベヤ | RF RF-<TRO> |

・バケットエレベータ | RF B |

・トレーエレベータ

|

RF NF |

・フライアッシュ用バケットエレベータ

|

RF-(FB) | |

・立体駐車機

|

RF 専用チェーン |

・バケット式連続アンローダ | 特殊チェーン | |

| 搬送物を押すまたは摩擦で動かす形式 | ・プッシャコンベヤ

|

RF NF RF-(NB) |

・スクレーパ/フライトコンベヤ

|

RF RF-(AM/AP) RF-(FG/FP) |

・水平循環コンベヤ

|

RF RF-(NB) RF-<GR> |

・フローコンベヤ

|

RF NFX |

|

| ・ドラグチェーンコンベヤ | WD | |||

注)

- 1. 搬送物の摩耗、腐食特性については各種溶媒に対する耐食性をご参照ください。

- 2. ()内は仕様記号、[]はローラ形式、<>は専用アタッチメント形式を示します。

3. チェーン形式の決定

チェーン形式の決定には、搬送物の性質を把握した上で搬送方法を決め、そのために最も経済的なチェーンコンベヤ形式を採用します。

コンベヤチェーンの使用方法は、上表の基本3形式とその他形式があります。用途に応じて前ページを参照のうえ、チェーン形式を決定してください。

| チェーン形式決定の留意点 |

|---|

|

4. ローラ形式の決定

大形コンベヤチェーンの構造の項の「ローラの形式」をご覧ください。

5. コンベヤチェーンの基本レイアウト

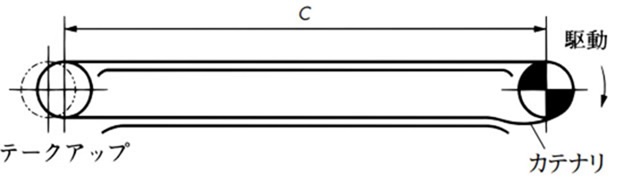

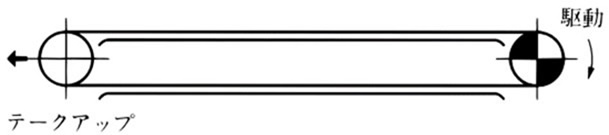

5.1 水平搬送の場合

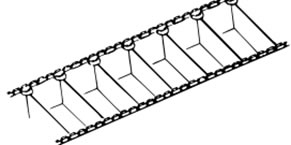

戻り側(図の下方)の一部または全部をカテナリとしたものは、チェーンの熱などによる伸縮を吸収できます。比較的低速の場合に使用可能で垂れ量は通常、スパンの1割程度が適当です。逆転のあるコンベヤに使用するのは困難です。

1) 駆動スプロケットの外れ側にカテナリをつくる方法

利点

- 1) カテナリ張力が駆動スプロケットの噛み合いを円滑にする。

- 2) チェーンに給油するときは、カテナリ部で行うと効果があります。

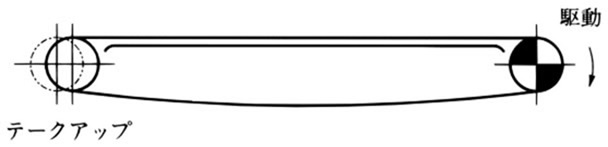

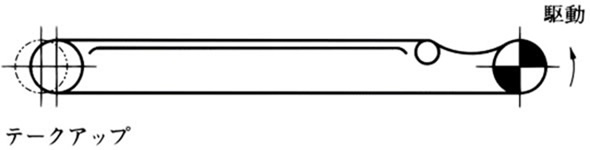

2) 戻り側を支持しない方法

機長が短く、低速のときに使用できます。

戻り側のチェーン質量による張力が振動の原因になり、スムーズな搬送ができないこともあります。

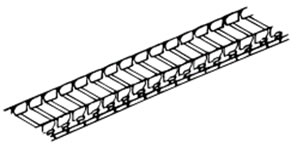

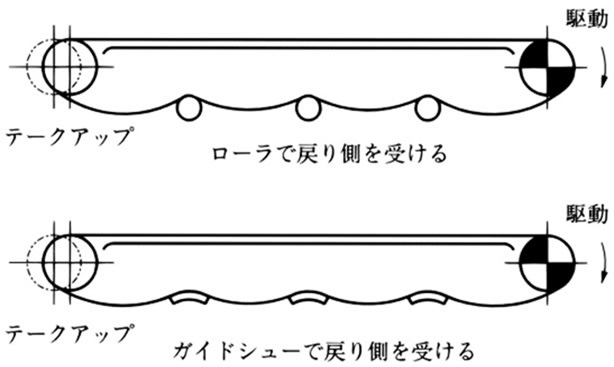

3) 戻り側をガイドまたはローラで受ける方法

チェーンがガイド、ローラと接し屈曲するので摩耗を早めたり、きずを生じやすくなることがあります。

またチェーンの振動が悪影響をおよぼすことがあり、機長が長い場合は分割してカテナリで受けることがあります。

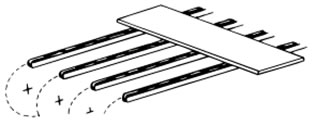

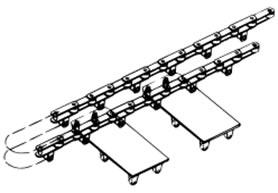

4) 戻り側をすべてガイドで受ける方法

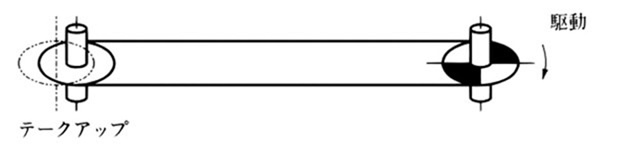

戻り側をすべてレールで支え、従動側のスプロケットにテークアップを装着し、チェーンのたるみを吸収する方法です。逆転のある場合にも採用できます。

ただし、カテナリが駆動スプロケットを出たところにありませんので、定期的にチェーンの伸びをテークアップで調整する必要があります。

注)テークアップの張過ぎは、チェーンの摩耗を早める原因となりますのでご注意ください。

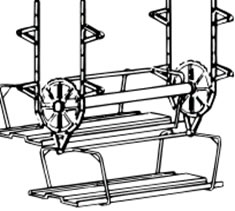

5) 戻り側が上方になる例

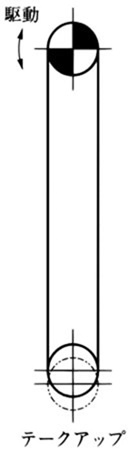

5.2 垂直搬送の場合

載荷のまま停止することがある場合は、逆転防止のため、駆動部にブレーキや、「つばきバックストップカムクラッチ」を設置する必要があります。

注)テークアップの張過ぎは、チェーンの摩耗を早める原因となりますので注意してください。

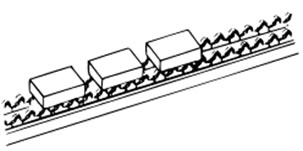

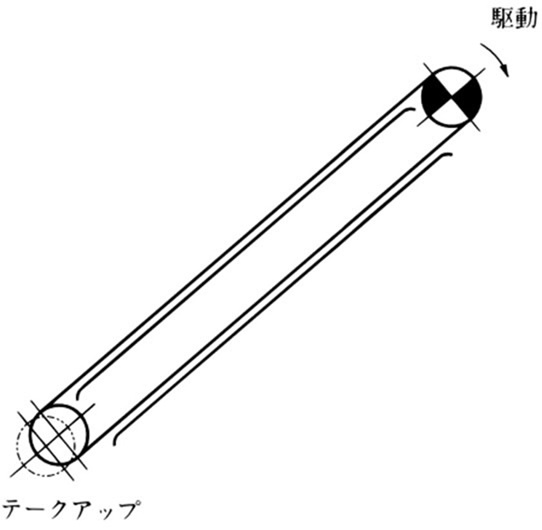

5.3 傾斜搬送の場合

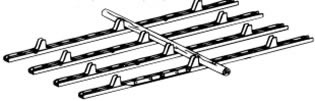

5.4 軸が垂直の場合

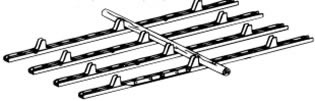

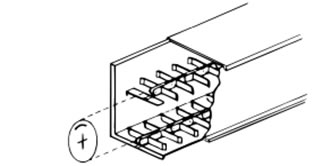

水平循環など軸が垂直の場合は、チェーンにガイドローラなどを取付けて、チェーンの運行をスムーズにします。

| コンベヤチェーン使用上の留意点 |

|---|

|

6. ばらもの搬送用チェーン仕様の決定

代表的なばらもの搬送物に使用されるチェーンコンベヤ形式、およびチェーン仕様を参考に掲げ、推奨チェーン仕様を示します。

搬送物によっては、同一名称でも状況・性質が表1と異なるものもありますので、従来の実績も考慮に入れ、十分にご検討のうえコンベヤ形式、チェーン仕様を決定してください。

表1. 搬送物とチェーン仕様

- 1. 搬送物の摩耗性については、大→中→小の順に摩耗性が小さくなることを示します。

- 2. 腐食性については、強酸性・酸性・中性・アルカリ性・強アルカリ性で示します。

- 3. 美麗仕様を使用するときは、美麗仕様をご参照ください。

| 搬送物 | 使用可能チェーンコンベヤ形式 | 推奨チェーン 仕様記号 |

備考 | |||||

|---|---|---|---|---|---|---|---|---|

| 名称 | 摩耗性 | 腐食性 | スクレーパ コンベヤ |

フロー コンベヤ |

エプロン コンベヤ |

バケット エレベータ |

||

| 米 | 小 | 中性 | ○ | ○ | ○ | DT | ||

| 大麦 | 小 | 中性 | ○ | ○ | ○ | 〃 | ||

| 小麦 | 小 | 中性 | ○ | ○ | ○ | 〃 | ||

| 大豆 | 小 | 中性 | ○ | ○ | ○ | 〃 | ||

| トウモロコシ | 小 | 中性 | ○ | ○ | ○ | 〃 | ||

| 小麦粉 | 小 | 中性 | ○ | ○ | ○ | 〃 | ||

| でん粉 | 小 | 中性 | ○ | △ | △ | 〃 | ||

| ケーン(さとうきび) | 小 | 中性 | ○ | ○ | DTA | |||

| バガス | 小 | 中性 | ○ | DTA | ||||

| 精製糖 | 小 | 中性 | ○ | ○ | ○ | SS | 注)3参照 | |

| 岩塩 | 小 | 中性 | ○ | △ | △ | DT | ||

| 混合飼料 | 小 | 酸性 | ○ | △ | △ | 〃 | ||

| ソーダ灰 | 中 | 強アルカリ性 | ○ | △ | △ | 〃 | ||

| カーバイド | 中 | ○ | ○ | ○ | ○ | 〃 | ||

| 芒硝 | 中 | 酸性 | △ | GS | ||||

| 生石灰(乾燥) | 中 | 強アルカリ性 | ○ | △ | △ | DT | ||

| 消石灰(乾燥) | 小 | 強アルカリ性 | ○ | △ | △ | 〃 | ||

| ポリエチレン | 中 | 中性 | ○ | △ | △ | 〃 | ||

| 塩ビ粉末 | 中 | △ | △ | MT | ||||

| カーボン | 中 | 中性 | ○ | △ | △ | BT | ||

| 活性炭 | 中 | 中性 | ○ | △ | △ | DT | ||

| 塩安(乾燥) | 小 | 中性 | ○ | △ | △ | 〃 | ||

| 硫安(乾燥) | 中 | 酸性 | ○ | △ | △ | 〃 | ||

| 尿素粉(乾燥) | 小 | 中性 | ○ | △ | △ | 〃 | ||

| 尿素粉(湿) | 中 | 強アルカリ性 | ○ | △ | △ | GS | ||

| 合成洗剤 | 中 | 中性 | ○ | △ | △ | DT | ||

| 石膏(湿) | 中 | 強酸性 | ○ | ○ | ○ | GS・RT | ||

| ドロマイト | 中 | アルカリ性 | ○ | △ | ○ | △ | DT | エプロンコンベヤの場合 DTA仕様 |

| 石灰石(乾燥) | 中 | アルカリ性 | ○ | △ | ○ | △ | 〃 | エプロンコンベヤの場合 DTA仕様 |

| 粘土(乾燥) | 中 | 中性 | △ | △ | BT | |||

| セメントクリンカー | 大 | 強アルカリ性 | ○ | △ | ○ | △ | CT | |

| セメント製品 | 中 | 強アルカリ性 | ○ | ○ | CT | |||

| ウッドチップ(乾燥) | 小 | アルカリ性 | ○ | △ | DT | |||

| おがくず(乾燥) | 小 | アルカリ性 | ○ | △ | DT | |||

| 石炭 | 中 | 酸性 | ○ | ○ | CT | |||

| コークス | 大 | 中性 | ○ | △ | BT | |||

| アルミナ | 中 | 強アルカリ性 | △ | △ | CT | |||

| 鋳物砂 | 大 | 中性 | ○ | △ | BT | |||

| スケール | 中 | 中性 | ○ | △ | △ | BT | ||

| コークスダスト | 大 | 中性 | △ | BT | ||||

| 石灰ダスト(湿) | 中 | 酸性 | △ | BT | ||||

| クリンカーダスト | 大 | 強アルカリ性 | △ | BT | ||||

| 生ゴミ | 中 | △ | ○ | RT | ||||

| 都市ゴミ焼却灰 (常温・乾燥) |

小 | アルカリ性 | ○ | DTA | ||||

| 都市ゴミ焼却灰 (水分含む) |

小 | アルカリ性 | ○ | RT | ||||