技術資料 大形コンベヤチェーン 選定

7. チェーンピッチとスプロケット歯数の決定

- 1. スプロケット歯数を多くすると、チェーンとスプロケットの噛み合いが円滑になり、屈曲角度も小さく、ピン・ブシュの摩耗が少なくなるので寿命が伸びます。

- 2. ピッチの大きいチェーンは、単位長さ当たりの価格は一般に安くなります。しかし、搬送物の積載間隔の都合で チェーンピッチの大きさが制約されることがあります。

[例]2m間隔で搬送物をプッシャーで押す場合には、偶数で割り切れるピッチ(100、200、250)のいずれかを選びます。 - 3. ばらもの搬送の場合は、搬送物の形状、性質、搬送容量、搬送速度などによって、チェーンに取付ける用具(バケット、エプロン)の大きさが決まり、用具の間隔によりチェーンピッチが決定します。

- 4. スプロケットのピッチ円直径がスペースから制約され、チェーンピッチが決まる場合もあります。

×(ドラッグで移動できます)

スプロケットの歯形ピッチに外接する円の直径。

(JIS B 1812:2015)

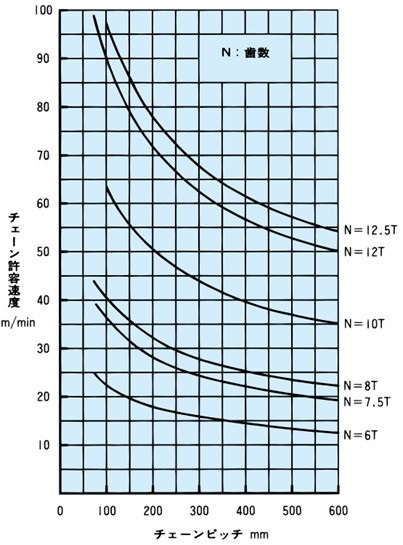

- 5. 一般的にチェーンピッチは、スプロケットの歯数とチェーン速度によって下図のように制約を受けます。チェーン速度は許容値以下にしてください。

表2. チェーンピッチとチェーン許容速度

注)バケットエレベータのように、チェーン本体に対して大きなジグを取付ける場合は、従来の実績も考慮に入れて、スプロケット歯数に対する許容速度に余裕を持たせてください。