Technical Data Pin gear drive unit

Selection procedure

Selecting pin gear drive unit pitch diameter

| During rotary movement : | Pre-select the pitch diameter of the pin wheel according to the size of the rotating device. Pre-select the pin gear pitch diameter from the reduction ratio. |

| Linear motion : | Pre-select the pitch diameter of the pin gear based on the equipment layout. |

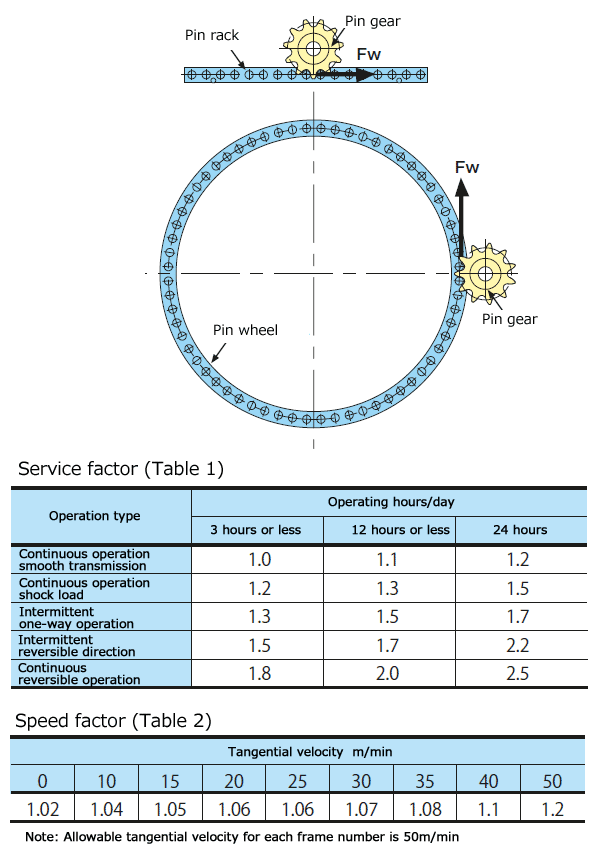

Calculating tangential load (Fw)

Calculate the tangential load (Fw) acting on a pin wheel or pin rack from the load conditions.

Calculating corrected tangential load Ft

Determine the service factor (KS, Table 1) from the running conditions and the speed factor (KV, Table 2) from the tangential speed. Then determine the corrected tangential load FT by multiplying it by the tangential load FW.

Selecting pin gear drive unit frame number

Using the allowable tangential load FP and corrected tangential load FT, select the appropriate frame number of the pin gear drive unit that satisfies the following conditions:

Selecting model No.

| Pin wheel : | Select the number of rollers of the pin wheel having the closest pitch diameter based on the selected frame number and pre-selected pin wheel pitch diameter. |

| Pin rack : | Work out the number of rack rollers from the selected frame number and travel distance (or moving distance). |

| Pin gear : | From the selected frame No. and tentatively selected pin gear pitch diameter, determine the model No. by selecting the number of teeth of the pin gear with the closest pitch diameter. |

| *The number of gear teeth that can be used is limited. If the number of teeth falls short, increase the tooth number and re-select. | |

Lubrication

Before running, be sure to apply extreme pressure grease to the outer peripheries of all rollers. Inner surfaces of the pin wheel/pin rack rollers are pre-lubricated. Please contact Tsubaki when lubricating grease cannot be used in applications such as

Special backlash specifications *These specifications differ from standard allowable tangential loads.

●Large backlash specifications

Large backlash enables easy mounting.

●Small backlash package

Can reduce backlash. (2/3 of standard backlash, available frame no.: PDU020-PDU120)

Installation method

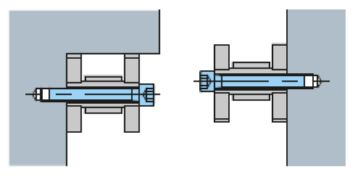

Flat & wheel type

Using a hole of the hollow pin, the side can be fixed to another device with bolts. On installation, you can decide the position by setting up a stopper or guide on one of the faces.

Angle type

The angle-style straight line rack can be fixed to another device by using the tightening bolt holes for fastening.

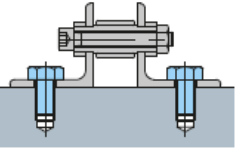

Mounting bolt location

Mount the bolts at both ends of a segment, and at equal spaces between them, using at least the minimum number of mounting bolts (see below).

Minimum number of mounting bolts per segment (horizontal installation)

| Specification | Frame number | Mounting bolt size | Minimum no. of mounting bolts |

|---|---|---|---|

| Steel type | PDU020 | M4 | 8 |

| PDU022 | M4 | 13 | |

| PDU030 | M6 | 10 | |

| PDU035 | M8 | 8 | |

| PDU040 | M10 | 7 | |

| PDU050 | M12 | 6 | |

| PDU055 | M12 | 9 | |

| PDU070 | M16 | 6 | |

| PDU080 | M16 | 7 | |

| PDU090 | M20 | 6 | |

| PDU120 | M30 | 4 | |

| PDU150 | M36 | 6 | |

| PDU180 | M42 | 6 | |

| PDU240 | M48 | 5 | |

| Stainless steel type | PDU020 | M4 | 8 |

| PDU022 | M4 | 13 | |

| PDU030 | M6 | 10 | |

| PDU035 | M8 | 8 | |

| PDU040 | M10 | 7 | |

| PDU050 | M12 | 6 | |

| PDU055 | M12 | 9 | |

| PDU070 | M16 | 6 | |

| PDU080 | M16 | 7 | |

| PDU090 | M20 | 6 |

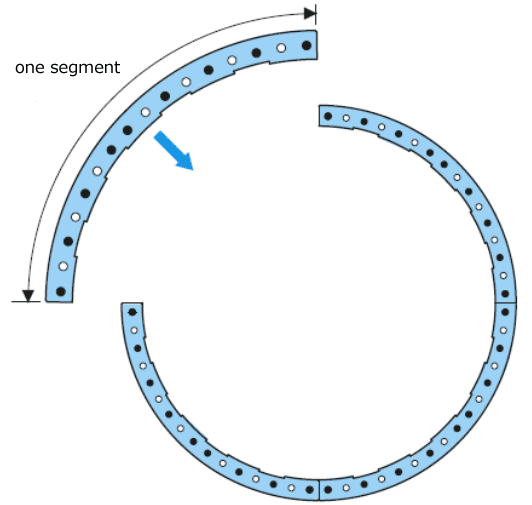

| (ex.) | Bolt mounting : | PDU050-GPF064P When divided into 4 segments |

| Mounting location : | See the diagram below (mounting locations are indicated with black circles) | |

| PDU050, minimum number of mounting bolts: 6 (M12) Mount more than 6 bolts for each segment as equally-spaced as possible. *Contact us if you have any questions regarding mounting. |

||

[Click to enlarge ]

Division of Pin Wheel & Pin Rack

For pin wheel/rack division, please refer to the following and check on the delivery drawing.

| ex. 1 | Pin wheel example : | ex. 2 | Pin rack example : | ||||

| PDU30-GW-190P: Split quantity 8 | PDU30-FR-200P: standard roller quantity 26P, minimum roller quantity: 10P | ||||||

| 23/190P×2 | ) | Combination | 26P×7 | ) | Combination | ||

| 24/190P×6 | 18P×1 | ||||||

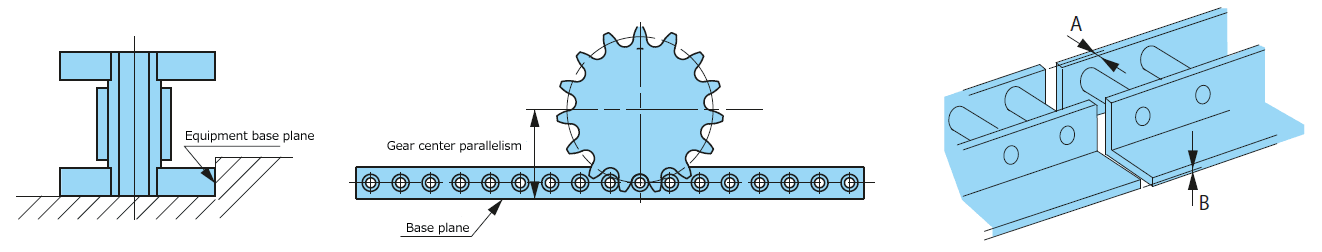

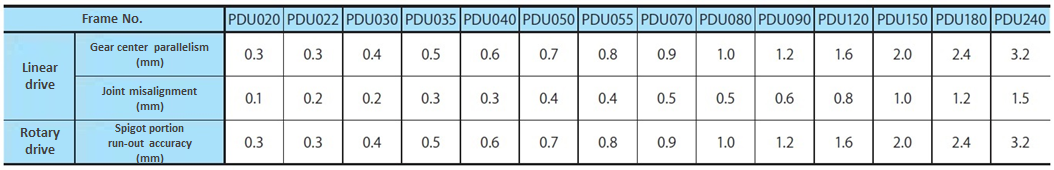

Installation accuracy

| Pin wheel : | The protruding surface of the pin wheel frame is machined to ensure concentricity with the roller mounting holes. It can be mounted by fitting it into the equipment spigot portion as the base level of centering. The accuracy of the equipment spigot p |

| Pin rack : | Predetermine the parallelism between the equipment to make sure that the parallelism of the pin gear center to the pin rack mounting base level on the equipment side is below the values shown in the "Gear center parallelism" table below. Install the unit |

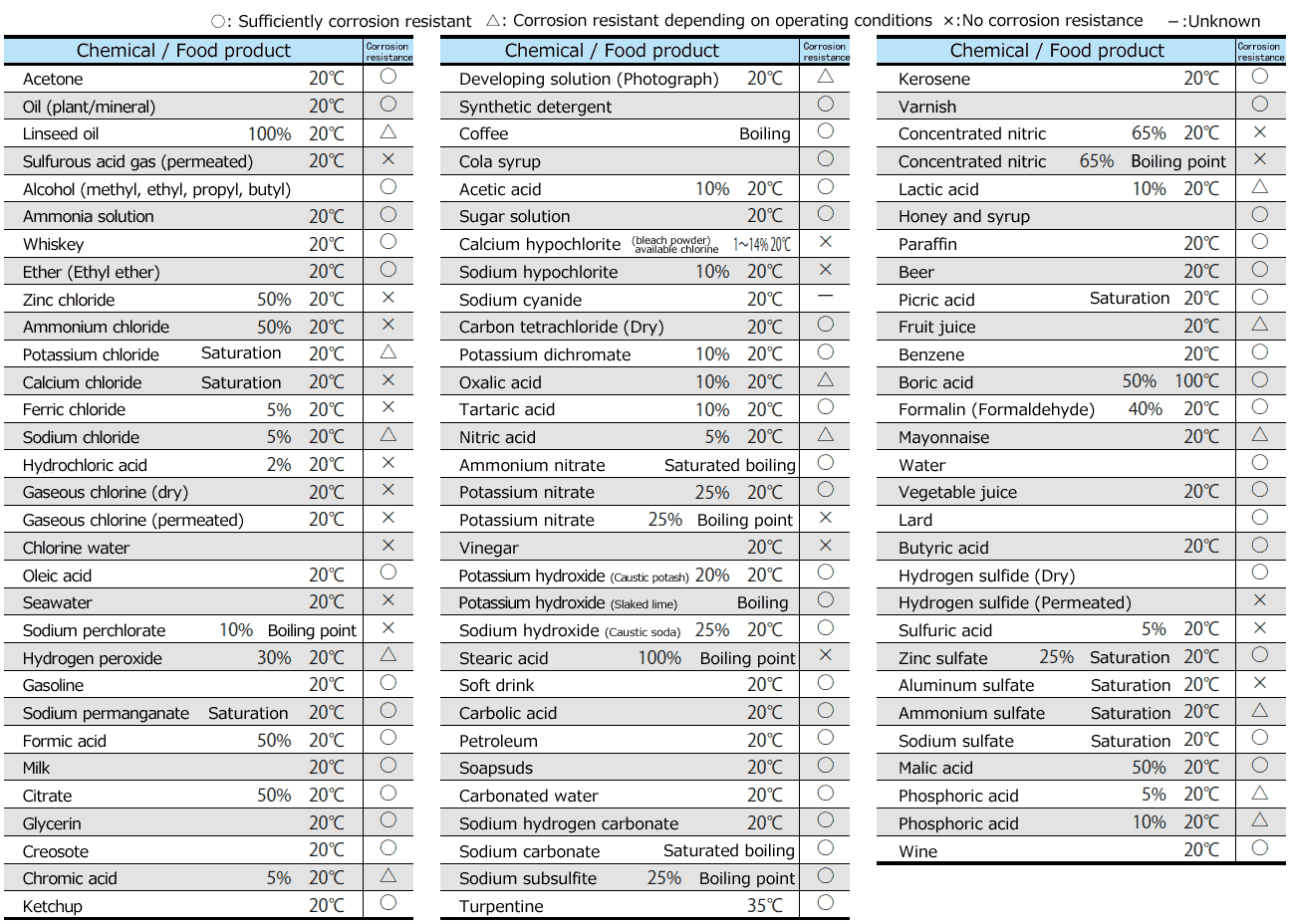

Reference data on corrosion resistance of stainless steel type

Corrosion resistance varies depending on operating conditions, and the table below does not show guaranteed levels. Use the following table to verify the corrosion resistance under the actual operating conditions by testing sample products.