技術資料 小形コンベヤチェーンスプロケット 取扱

据付け

1. スプロケットの取付け

スプロケットの取付けの良否は、コンベヤのスムーズな運行に大きな影響を与え、アタッチメント付小形コンべヤチェーンの寿命を左右します。

取付けは下記要領で正しく行ってください。

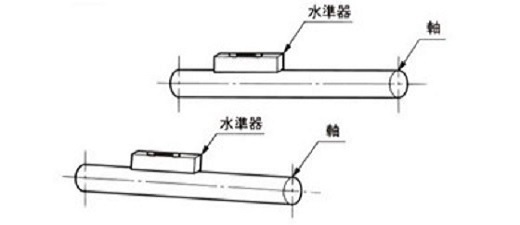

(1)水準器で軸の水平度を出します。

精度は±1300以内に調整します。

図1.軸の水平度

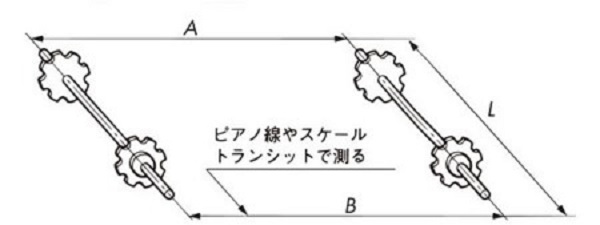

(2)軸の平行度を出します。

精度はA-BLが±1100以内に調整します。

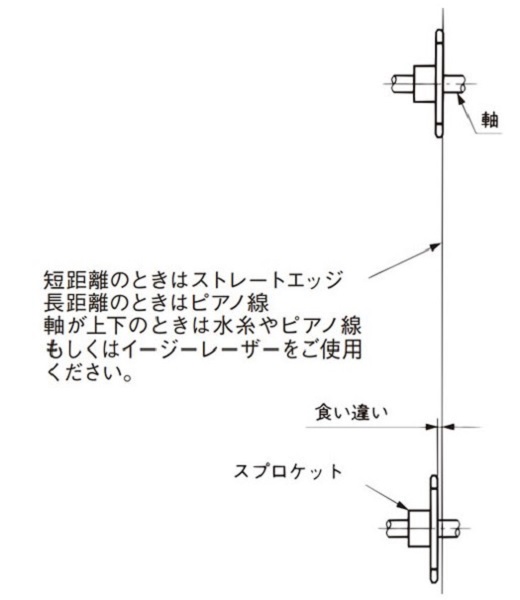

(3)一対のスプロケットの食違いを修正します。

- 軸間距離1mまで:1mm以内

- 軸間距離1m~10m:軸間距離(mm)1000以内

- 軸間距離10m以上:10mm以内

図3.スプロケットの食違い

(4)(1)~(3)の調整後、スプロケットをキー、つばきパワーロックなどで軸に固定します。

並列使用のスプロケットは、軸心上の2枚の歯が同位相となるようにして固定します。

2. 心出し

チェーンコンベヤはチェーンが案内レールにそって走行するので、レールはとくに工作精度を高めるとともに、心出しを正確にする必要があります。

垂直バケットエレベータのように案内レールがない場合には、コンベヤの心出しが正確でないとチェーンが蛇行してチェーンの寿命に大きく影響します。

3. レール

一般的に、レールの摩耗は、チェーンの摩耗よりも早く起きます。

レール材質は、チェーン材質との組合せが大切ですが、一般には一般構造用圧延鋼材(SS400)やプラスチック材(超高分子量ポリエチレン)を推奨します。

- (1)摩耗は種々の要因(腐食、潤滑、負荷速度、稼働時間など)があり複雑です。正確にチェーン寿命とレール材の関係を推定することは難しいものです。

- (2)チェーン寿命はレールとの組合せに左右されます。新設の場合は、チェーンよりレール材の硬さをわずかに低いものにして摩耗状態を確認します。レール材表面が滑らかに仕上げられる程度が良いでしょう。

- (3)材質の決定は、使用条件を考慮してください。衝撃のかかるときや特殊な雰囲気では、プラスチックは使用できない場合があります。

- (4)運転前のレールに関する注意

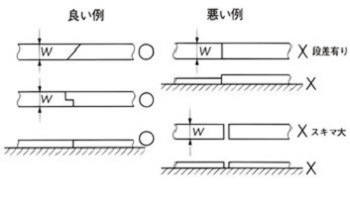

- 1. レールの継ぎ部は滑らかにし、エッジを除き、段差、隙間はなくす。(図4)

- 2. 溶接時のスパッタやスケールは取除いてください。

- 3. 試運転時は無負荷でチェーンに給油し、チェーンとレールの状態を確認してください。

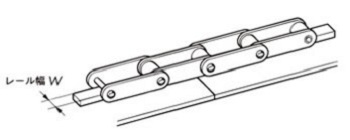

レール幅 W:一般的にはスプロケット歯幅とします。

レールの熱膨張を考慮したスキマは必要です。

図4.レールの接続

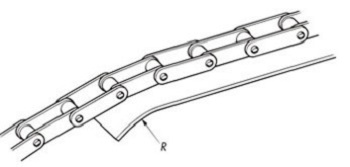

チェーンの出入口には、レールにRをつけて、チェーンの運行を滑らかにします。

図5.チェーンの出入口のレール