技術資料 トップチェーン 選定

スナップカバー®チェーン設計資料

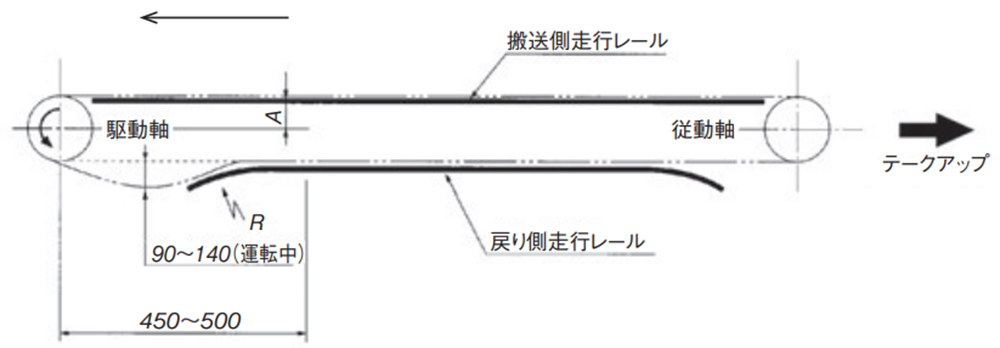

走行レールの基本

搬送はチェーンの引っ張り側で行い、たるみ側はチェーンの振動・コンベヤの脈動を防ぐため両端をゆるやかに曲げた走行レールで受けます。

チェーンのたるみ

駆動スプロケットの下側に90~140(運転中)のたるみが必要です。

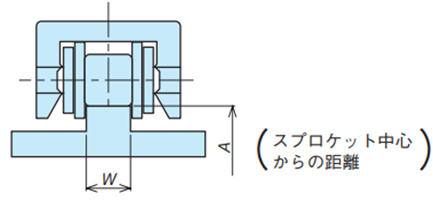

走行レールの高さ

A = スプロケットのピッチ円直径 - ローラ径 2

走行レール端部の曲げ

走行レールのR寸法は、チェーンのバックベンド半径R(下表)より大きくします。

| RF06B-SC | RS40-SC | RS50-SC | RS60-SC | RS80-SC | RS100-SC | |

|---|---|---|---|---|---|---|

| バックベンド半径R mm | 280 | 380 | 480 | 560 | 740 | 880 |

チェーンのガイド

- ・搬送側...必ずチェーンのローラで受けてください。プラスチックカバーで受けるとプラスチックカバーが早期に摩耗します。

- ・戻り側...プラスチックカバー全面を受けてください。

[搬送側]

レール幅(W):

一般的にはスプロケット歯幅とします。

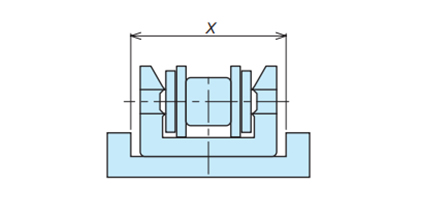

[戻り側]

戻り側溝幅(X):

チェーン幅(L) + 2~3mm