技術資料 トップチェーン 取扱

4-3. スプロケットの取付ピッチの決定

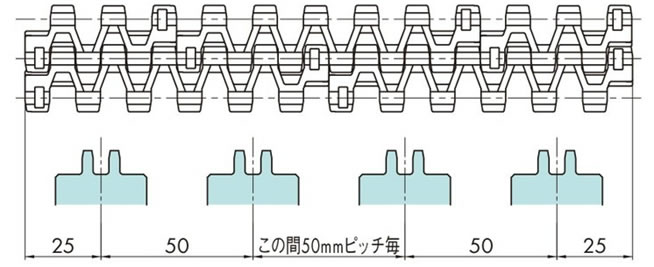

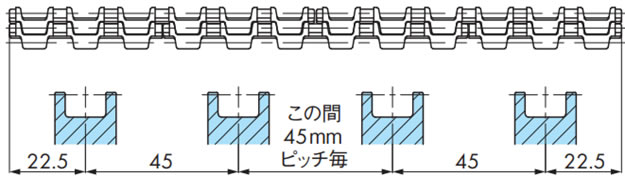

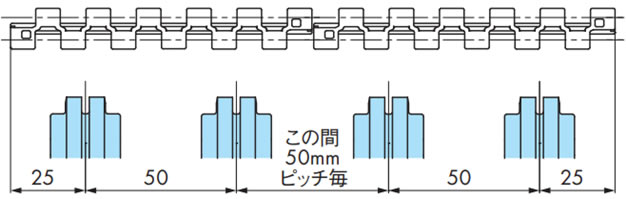

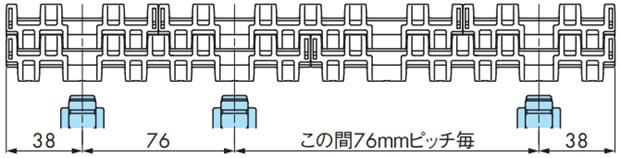

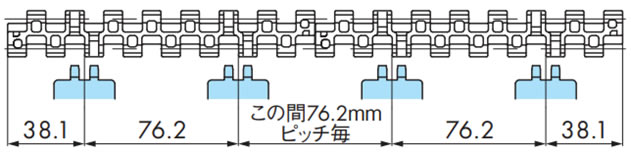

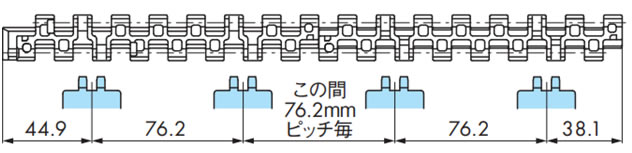

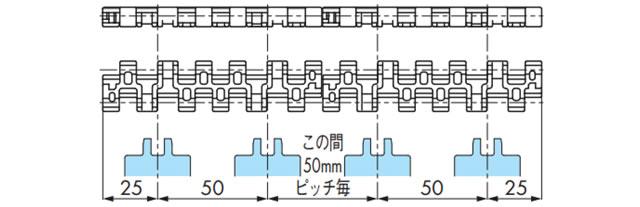

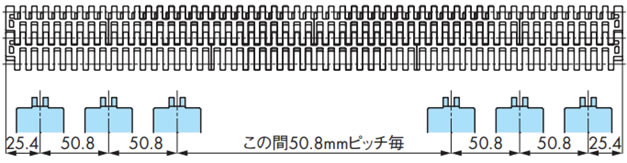

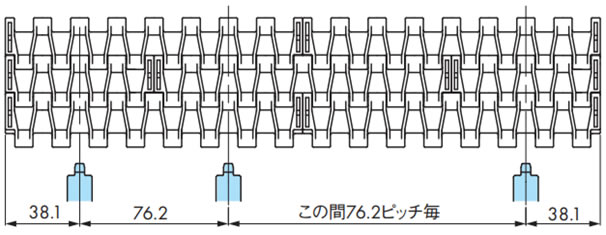

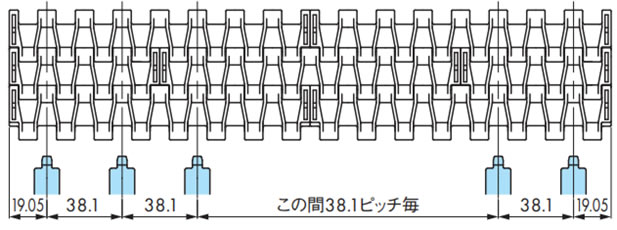

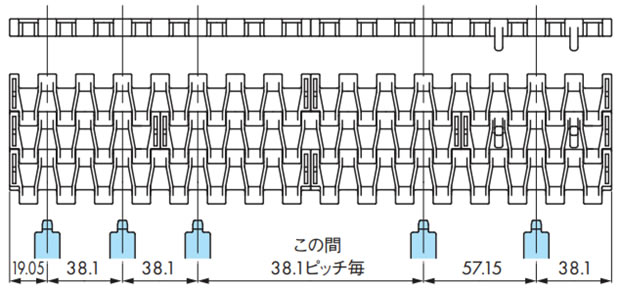

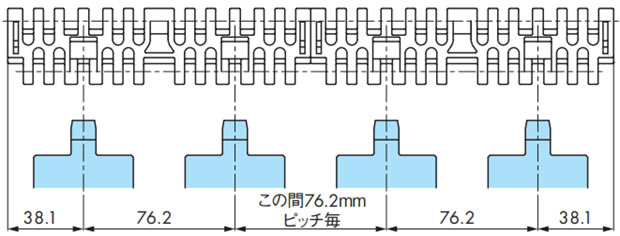

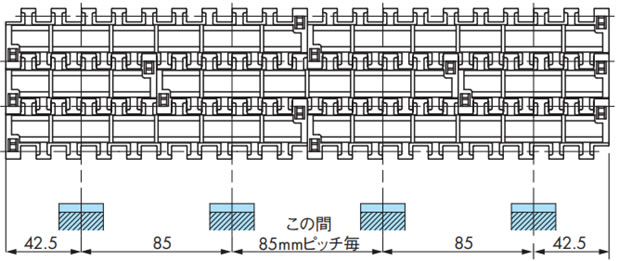

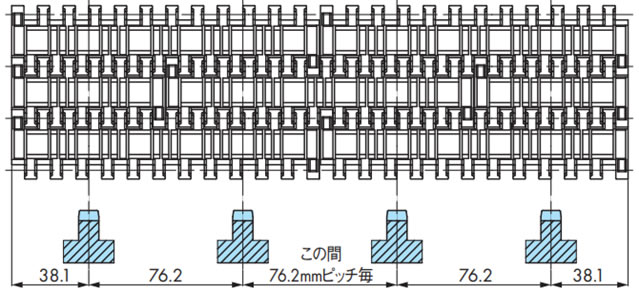

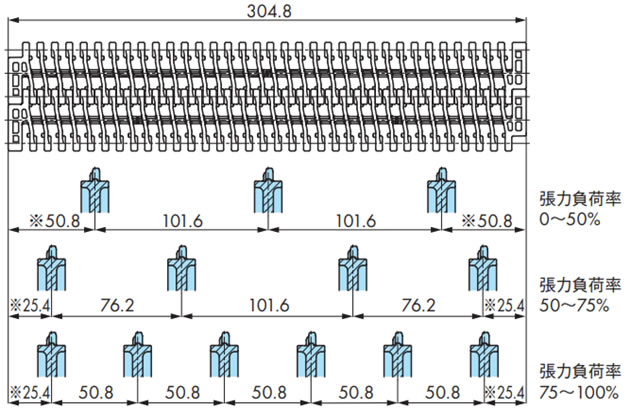

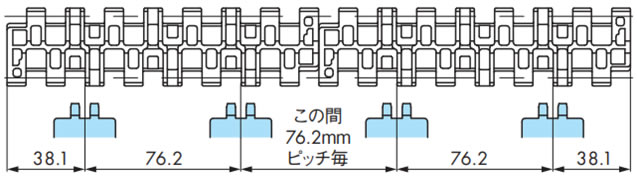

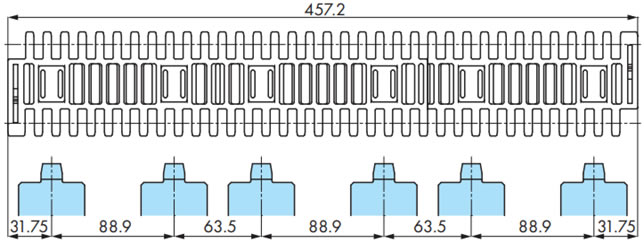

各チェーンのスプロケットの取付けピッチ図を下記に示します。

手順6の(2)式で求めたチェーン幅1m換算張力F'がチェーンの許容張力(幅1m当たりのMAX)の何%のレベルかを確認します。

チェーン張力負荷率F1により変わる場合もありますので、ご注意ください。

張力負荷率F1(%)の計算

F1 = 100F' A ...(3)

F'...手順6で求めたチェーン幅1m換算能力 kN/m{kgf/m}

A...各使用温度におけるチェーン幅1m換算能力 kN{kgf}

チェーン能力線図を参照ください。

幅広タイプ

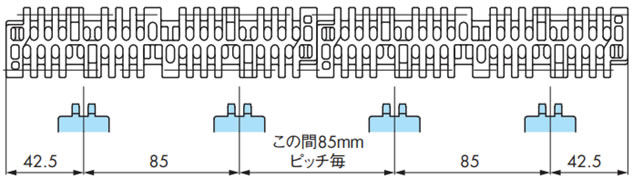

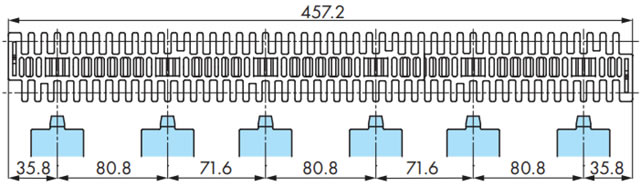

(1) WT0405-W形

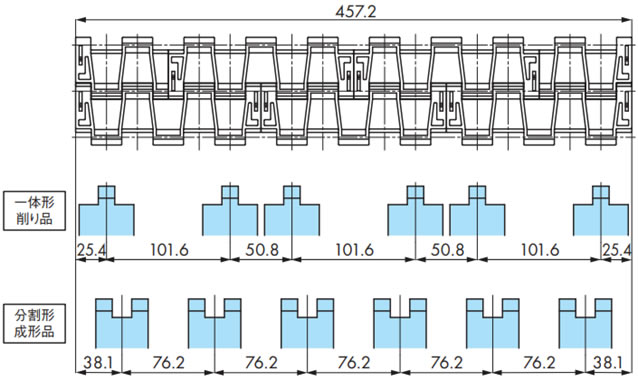

(2) WT0705-W形

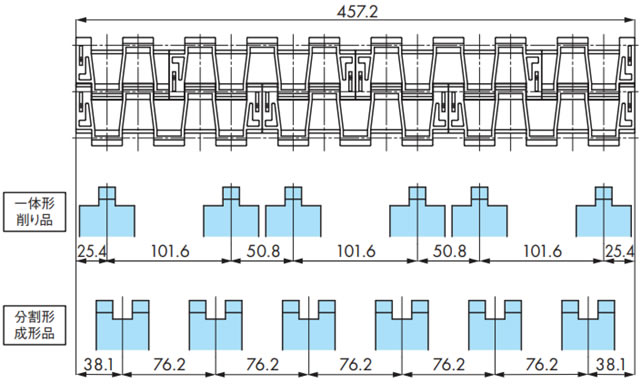

(3) BTN5形、BTN5-A形

注)BTN5-A(蛇行防止アタッチメントあり)には、スプロケットBT5-24Tは使用できません。BT5-32Tをご検討ください。WT-SW1500-24Tは使用できます。

(4) WT1505-K形、WT1505RN-K形、WT1505G-K形、WT1506-K形

(5) WT1505GTO-K形、WT1505GTORN-K形

(6) WT1515-W形、WT1516-W形、WT1515G-W形、WT1515(T-)F-W形、WT1516(T-)F-W形、WT1515VG-W形

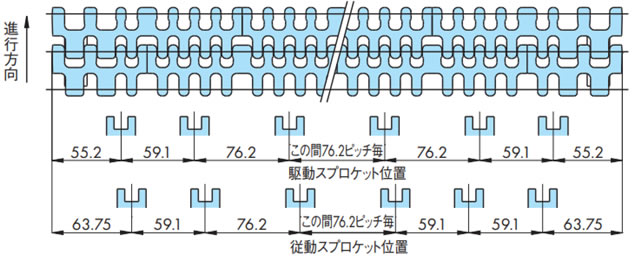

(7) WT1907-K形

注)奇数インチ幅の場合、取付ピッチが1ヵ所76.2mmになります。中央付近で調整ください。

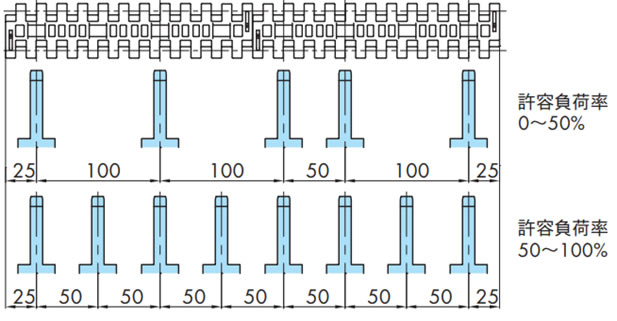

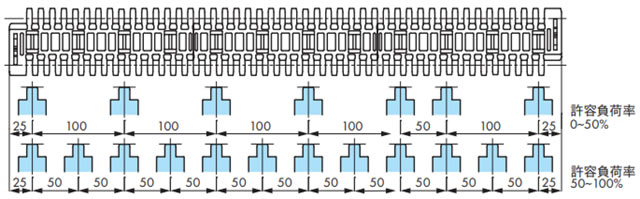

(8)BT6シリーズ、BTC8形、BTC8-A形

・張力負荷率(F1)が50%以下の場合のスプロケット取付ピッチ

(9)BT6シリーズ、BTC8形

・張力負荷率(F1)が50%を超える場合のスプロケット取付ピッチ

(10)BTC8-A形

・張力負荷率(F1)が50%を超える場合のスプロケット取付ピッチ

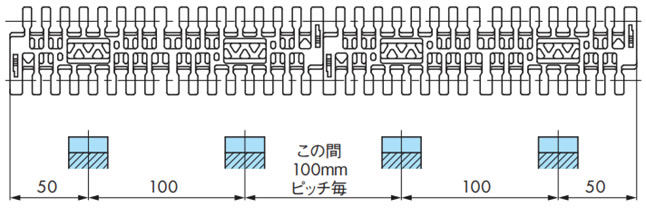

(11)WT2505-K形、WT2506-K形、BTM8H形

(12)WT2515-W形、WT2515G-W形、WT2515F-W形

(13)WT2250FG、VG

(14)BTC8S形、WT2525-K形、WT2525VG-K形

(15)WT2705-K形/WT2706-K形

注)

- 1. ※位置には必ずスプロケットを配置してください。

- 2. 奇数インチ幅の場合、取付ピッチが1ヵ所変則ピッチになります。中央付近で調整ください。

(16)WT3005-K形/WT3005G-K形

(17)WT3086-K形/WT3086G-K形

(18)WTU3015T-K形

注)駆動スプロケットと従動スプロケットで配置が異なります。

(19)WT3109-W形

注)許容負荷率0~50%のスプロケット配置の場合、1ヵ所は50mm配置になります。

(20)WT3816-K形

(21)WT3827-K形

(22)WT3835-K形

(23)WT3835-T形(浮上がり防止アタッチメント(タブ)あり)

(24)BTH16

注)許容負荷率0~50%のスプロケット配置の場合、1ヵ所は50mm配置になります。

(25)WT5707-K形

(26)WT1306-W形