技術資料 クラッチ 潤滑

潤滑とメンテナンス

推奨潤滑油とグリース

適正な潤滑は、カムクラッチに長時間、充分な機能を発揮させる上で必要なメンテナンスです。用途に適した正しい潤滑を以下の記載どおり行ってください。

1. カムクラッチ用オイル

| 使用法 | オーバランニングまたはバックストップ | インデキシング | ||

|---|---|---|---|---|

| 許容回転速度の1/3以下 周囲温度30℃以下 |

許容回転速度の1/3以上 または周囲温度30℃以上 |

|||

| オイル銘柄 | シェルルブリカンツジャパン | ターボオイルT32、リムラD10W、 ゲルコATF |

リムラD30 | - |

| ENEOS | DTEオイルライト、 マルチパーパスATF、ATF220 FBKタービン32、オートマチックD2、 FBKオイルRO32、RIXタービン32、 ATFII(N) |

FBKオイルRO68 | - | |

| 出光興産 | ダフニータービンオイル32、 アポロイルATF-DX |

アポロイルジーゼルモーチブS-330CF | ダフニーオイルCR10 | |

| コスモ石油ルブリカンツ | コスモタービンスーパー32、 コスモタービン32、コスモATF2 |

コスモディーゼルCF30 | - | |

| 三和化成 | - | - | サミックアークティックオイルライト | |

2. カムクラッチ用グリース

| グリース | 適用クラッチ | シェルルブリカンツジャパン | ENEOS | 協同油脂 | エクソンモービル・ジャパン | コスモ石油ルブリカンツ |

|---|---|---|---|---|---|---|

| 万能グリースLi系 | 一般用 | シェルガダスS2 V125J 2 (S)、 サンライトグリース2 |

マルティノックグリース2 | ユニルーブNo.2 | - | ダイナマックス スーパーNo.2 |

| BSシリーズ BRシリーズ |

シェルガダス S2 V125J 1 (S)、 サンライトグリース1 |

マルティノックグリース1 | マルテンプPSNo.1 | - | ダイナマックス スーパーNo.1 |

|

| BBシリーズ MLシリーズ |

- | - | - | ビーコン325J | - |

- 1. 極圧添加剤の入っている潤滑油(脂)の使用は避けてください。

- 2. 上記グリース潤滑の場合、カムクラッチが正しく機能できる使用周囲温度範囲は-5℃~40℃です。これを超える温度条件の場合は当社までご相談ください。

- 3. カムクラッチ用純正潤滑油(脂)を用意していますのでご利用ください。

| 純正潤滑油(脂) | 容量 | 用途 |

|---|---|---|

| カムクラッチ用純正潤滑油 | 1L | オーバランニングまたはバックストップ (許容回転数の1/3以下) |

| カムクラッチ用純正潤滑油 (インデキシング用) |

1L | インデキシング |

| カムクラッチ用純正グリース | 500g | 使用周囲温度-5℃~40℃ |

潤滑形式とメンテナンス

潤滑形式がオイル潤滑のシリーズは、出荷時に潤滑油を封入していませんので、ご使用前に適正潤滑油を注入してください。

| シリーズ | 潤滑形式 | メンテナンス | |

|---|---|---|---|

| MZ・MZ-G・LD MA・BB・ML |

グリース潤滑 | 出荷時にグリース封入済です。BBシリーズをオイル潤滑で使用する場合はオイルバスとし、油面高さは軸心以上としてください。 | |

| 200・PB | グリース潤滑 | 6ヵ月に一度内部を洗浄し、新しいグリースと入替えてください。 | |

| オイル潤滑 | オイルバス形式の潤滑をしてください。オイルの交換は3ヵ月に一度行ってください。 | ||

| MG・MI・MI-S・MR | オイル潤滑 | 100時間毎に補充し、3ヵ月に一度古いオイルを排出して、内部を洗浄後、新しいオイルを入替えてください。 | |

| MX | オイル潤滑 | 300時間毎に古いオイルを排出して、内部を洗浄後、新しいオイルと入替えてください。 | |

| MG-R | オイル潤滑 | 300時間毎に補充し、3ヵ月に一度古いオイルを排出して、内部を洗浄後、新しいオイルと入替えてください。 | |

| BR | パッケージタイプ | グリース潤滑 | 出荷時にグリース封入済です。3ヵ月毎に補充してください。 |

| オープンタイプ | グリース潤滑 | 3ヵ月毎に補充してください。 | |

| オイル潤滑 | 6ヵ月に一度古いオイルを排出して、内部を洗浄後、新しいオイルを入替えてください。 | ||

| BS | 30~135 | グリース潤滑 | 出荷時にグリース封入済です。 |

| 160~350 | グリース潤滑 | 1年に一回古いグリースを排出し、内部を洗浄後、新しいグリースを注入してください。 | |

| 425, 450 | オイル潤滑 | 3ヵ月毎に補充し、6ヵ月~1年に一度古いオイルを排出し、内部を洗浄後、新しいオイルと入替えてください。 | |

| カムクラッチボックス | オイルバス 自己循環方式 循環オイルバス方式 外部強制給油 |

仕様決定時詳細について打合せします。 | |

潤滑油の注入法

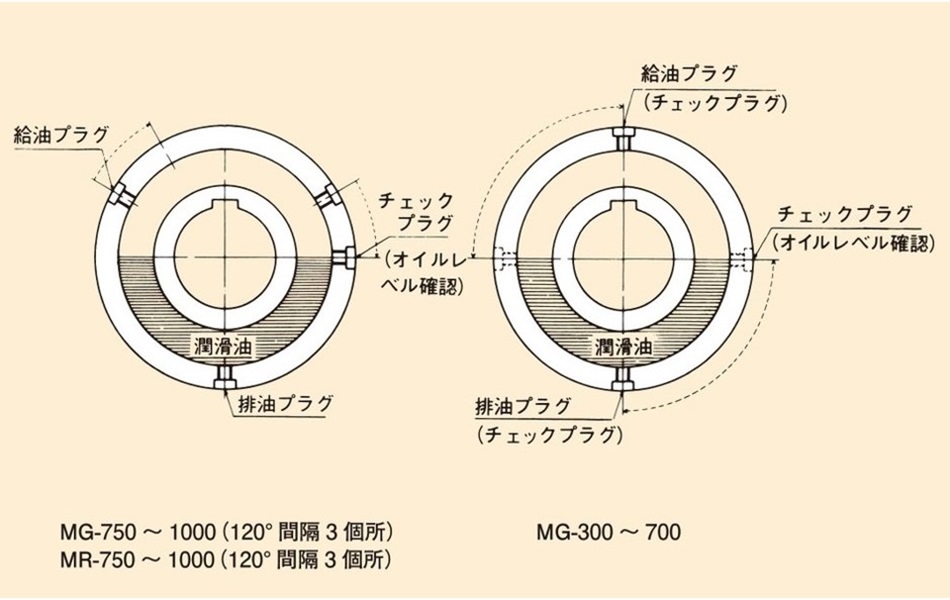

1. MG.MRシリーズの潤滑油注入の方法

- 1. 潤滑油量は、オーバランニング、バックストップについては原則として軸心の高さまでです。

- 2. 各シリーズの外輪には、2~4カ所のプラグがあります。

- 3. 4個のプラグが利用できるものは、各プラグを上、中、下の位置にし、上部と中間のプラグを外し、上部より給油し、中間のプラグからオイルが出るまで入れてください。

- 4. 3個のプラグが利用できるものは、1個のプラグを下部にし、上部2個のプラグを外して、いずれかから給油してください。上部いずれかのプラグの位置を軸心の高さまで回転させ油量を確認してください。

- 5. 2個のプラグしかないものは、上部プラグのみを外して、そのプラグから給油してください。更にプラグを90°回転させて軸心まで油が入ったかどうかを確認してください。

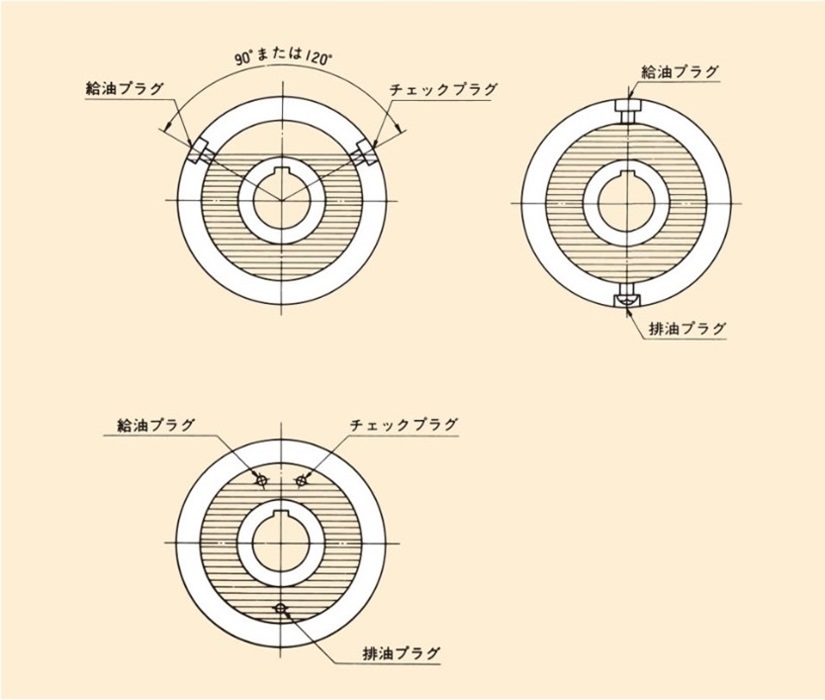

2. MI.MI‐S.MX シリーズの潤滑油注入の方法

- 1. 給油量は、ほぼ満杯まで入れてください。

- 2. 外周または側面にプラグがあります。

- 3. 外周のプラグ3~4個を利用できるものは、プラグ位置を少し傾けて、隣のプラグからオイルが出てくるまで給油してください。

- 4. 2個のプラグを利用できるものは、油差しの先端をプラグに差し込み、オイルがあふれるまで給油してください。

- 5. 側面のプラグを利用できるものは、2個のプラグが並んでいる側を上にして両方共プラグをあけ、一方からオイルを入れ、片方からこぼれるまで給油してください。

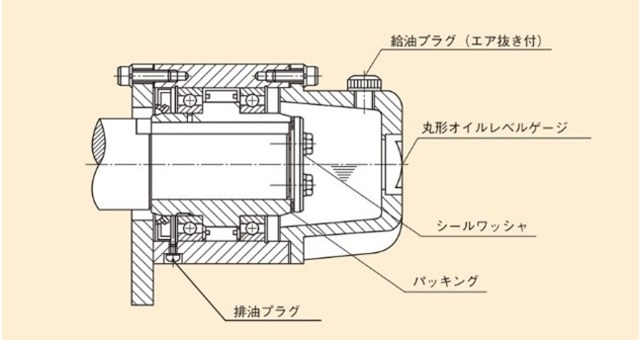

3. MG-Rシリーズの潤滑油注入の方法

- 1. 潤滑油量は、原則として軸心の高さまでです。オイルリザーバについている丸形オイルレベルゲージにて確認してください。

- 2. 外輪には、4ヵ所~3ヵ所プラグがついています。そのうち1ヵ所を排油プラグとして利用できるよう、真下に位置するよう取付けてください。また、給油はオイルリザーバの給油プラグから行ってください。したがって、給油プラグは真上に位置するようオイルリザーバを取付けてください。

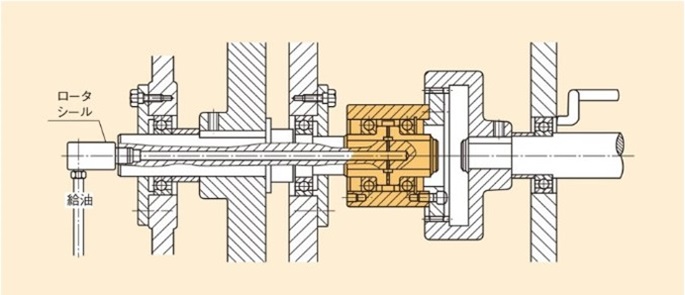

4. 特殊な給油方法

カムクラッチを、機械装置の内部に組込み使用する時には、通常のメンテナンスが困難なため特殊な給油方法が必要です。左図にその一例を示します。シャフトに貫通プラグを設けロータシールから強制給油を行う方法です。