技術資料 大形コンベヤチェーン 選定

11. チェーンサイズの決定

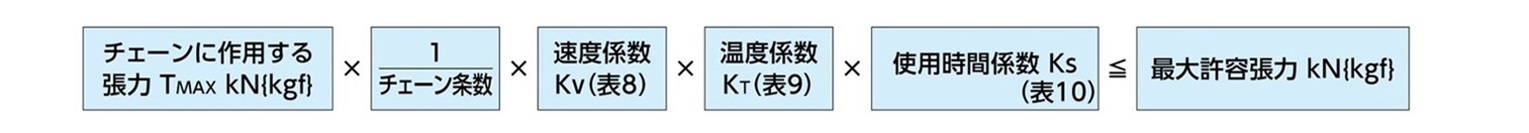

表3で求めたチェーンに作用する張力(TMAX)をチェーン条数で除し、チェーン速度~温度係数と使用時間係数を乗じて補正チェーン張力T'MAXを求め、これを満足する最大許容張力を有するチェーンを選定します。 (コンベヤチェーンの最大許容張力は、当社の設計基準に基づき算出した計算強度です。)

×

(ドラッグで移動できます)

潤滑状態での使用を前提とし、疲労破壊、摩耗を加味した限界値です。弊社カタログに記載された選定を基に補正チェーン張力を求め、この値以下でお使いいただいた場合、早期に異常を生じることはありません。 ただし、特殊雰囲気における性能低下を生じた場合は除きます。

- 1) チェーンの選定に関して法や指針による規制があるときは、それによる選定と、許容張力選定の両方を行い、余裕のある方のチェーンをご選定してください。

- 2) コンベヤチェーンを多条で使用する場合は、偏荷重が作用することがあります。このときは、上式の1/チェーン条数の値を補正してください。

- 3) (1)大荷重の近距離搬送 (2)摩耗性、付着性、腐食性のある搬送物がふりかかる (3)高温、高湿の雰囲気 (4)無給油でのチェーンの使用は、チェーンの寿命が大幅に減少します。特殊な雰囲気におけるチェーンの使い方も参考にしてご選定ください。

- 4) 上記3)項のうち、特に無給油でチェーンをご使用時は、摩耗寿命に配慮し1.3~1.5程度の余裕を見込んでください。

表8.チェーン速度係数 Kv

| チェーン速度 m/min | 速度係数 Kv |

|---|---|

| 20以下 | 1.00 |

| 20を超え~30以下 | 1.05 |

| 30を超え~40以下 | 1.15 |

| 40を超え~50以下 | 1.30 |

| 50を超え~60以下 | 1.45 |

注)適性な使用条件(清浄・給油状態良好)での基準としてください。

表9.チェーン温度係数 KT

| チェーン温度 ℃ | 温度係数 KT | ||

|---|---|---|---|

| DT・DTA | AT・ATA | GS・GSA SS・SSA |

|

| 100以下 | 1.00 | 1.00 | 1.00 |

| 100を超え~200以下 | 1.25 | 1.20 | 1.00 |

| 200を超え~300以下 | - | 1.35※ | 1.10 |

| 300を超え~400以下 | - | 1.50※ | 1.15※ |

- ・高温かつ高速でのご使用の場合は、チェーンの寿命が著しく短くなります。(表9※印部)

- ・上記以外の仕様については、お問合せください。

- ・KV×KTの値がDT、DTA、AT、ATAで1.5を超える場合は当社へお問合せください。

- ・KV×KTの値がGS、GSA、SS、SSAで1.2を超える場合は当社へお問合せください。

- ・チェーンの使用雰囲気温度は各製品ページにてご確認ください。

表10.使用時間係数 Ks

| 1日の使用時間 | Ks |

|---|---|

| 10時間以下 | 1.0 |

| 10~24時間 | 1.2 |