技術資料 ドライブチェーン ローラチェーンの選定

9. チェーン式ピンギヤの紹介

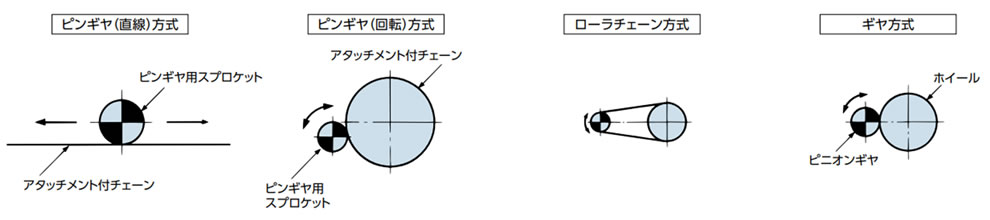

直線運動や大径で回転運動をさせるために、一般には駆動源(モータなど)より減速機を経て、ローラチェーン・ギヤが使用されます。

しかし、ローラチェーン方式ではスペースを要する、ギヤ方式では精密加工を要する、コスト高になる、などの問題に直面します。

このようなときにピンギヤ方式が最適です。

ピンギヤ駆動は、ローラチェーンをドラムの外周に巻き付けてホイールとし、ピニオンギヤの代わりに特殊歯形のチェーン式ピンギヤ用スプロケットを用います。

直線運動のときは、ラックの代りにローラチェーンを直線に取付け代用します。

| 項目 | ピンギヤ方式 | ローラチェーン方式 | ギヤ方式 |

|---|---|---|---|

| 軸間距離の制約 | あり | なし | あり |

| 噛み合い歯数 | 少ない | 多い | 少ない |

| 速比範囲 | 無制限 | 1:7まで | 無制限 |

| 歯形 | 特殊歯形 | スプロケット歯形 | インボリュート |

| 噛み合い精度 | 普通 | 普通 | 精密 |

9.1 ピンギヤの特長

- 1. 大速比(1:5以上)で、特にドラム径が大きい場合に経済的です。

- 2. ローラチェーンのアタッチメントをドラムなどにボルト止めするだけで、取付けも保守も容易です。

- 3. ドラム外径、直線長さなど設計の自由度が大きくなります。

- 4. 極めて正確な駆動には適さず、ギヤに比べて騒音は高くなります。しかし、据付けに高い精度を要さず、ギヤのような精密加工は不要です。

- 5. グリース潤滑が使用できます。

9.2 チェーンの取付方法および注意事項

1. 直線(ラック)で使用、ローラ上向きの場合

RSローラチェーンを使用

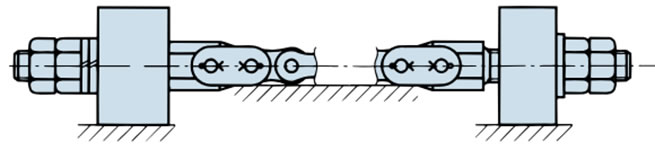

両端に継手リンクを使用し、金具を付けてチェーンのたるみがなくなる程度にボルト、ナットで締め付けるようにします。両端をダブルナットなどの緩み止めを施します。

ピンギヤ用スプロケットの歯先がレールと干渉することがあるため、取付け時はチェーンのローラをレールで受けないでください。

RSローラチェーンを使う方法は、歯飛びや歯の干渉が生じやすいため、推奨いたしません。

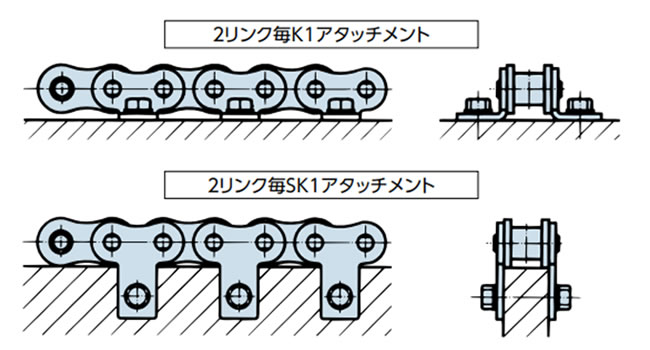

アタッチメント付RS形チェーンを使用

2リンク毎K1、SK1外リンクアタッチメント付とし、チェーンのたるみと蛇行がないように真っ直ぐに張り、2~4リンク毎にボルト・ナットで締め付けます。Kアタッチメントを推奨します。

取付け穴加工は現物合わせで行います。

注) SK1アタッチメントの場合はチェーンのローラを受けないでください。ピンギヤ用スプロケットの歯先がレールと干渉することがあります。

使用ボルトは、強度区分8.8以上(JIS B 1051:2014 呼び引張強さ800MPa以上)をご使用ください。

(例、SCM435熱処理ボルト)

注) チェーン長さは、使用条件によりオーバランをする分を見込み、移動距離よりも長めに設計します。

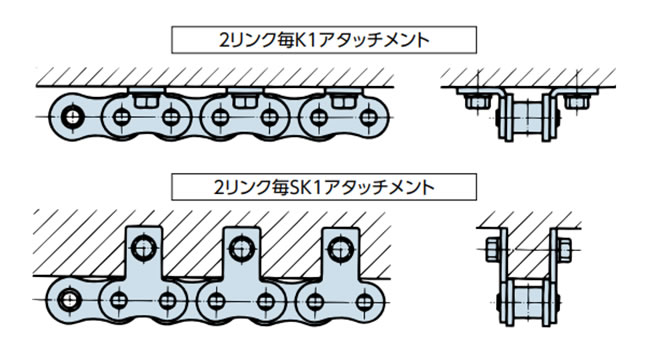

2. 直線(ラック)で使用、ローラ下向きの場合

2リンク毎K1、SK1外リンクアタッチメントとし、チェーンのたるみと蛇行がないように真っ直ぐに張り、2リンク毎にボルト・ナットで締付けます。取付け時は、チェーンのローラを受けないでください。

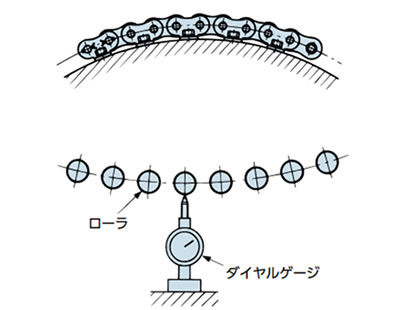

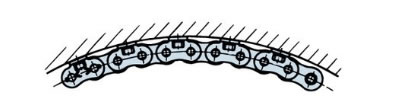

3. ドラム外周に全周巻きの場合と、部分巻きの場合

- ・アタッチメント付ローラチェーンの長さは、基準長さ(称呼ピッチ×リンク数)に対し、-0.05~0.15%の範囲で製作されています。したがって、ドラムに巻き付けると、チェーンがたるむことがあります。ドラムとチェーンアタッチメントの間にシムを入れてたるみを調整します。

- ・Kアタッチメントは、シム調整ができます。SKアタッチメントよりもドラム外周への取付けが容易です。

- ・ドラムが真円でない場合は、チェーンを巻き付ける時に、真円となるようにシム厚を調整します。

右図のようにダイヤルゲージ、トースカンなどの測定器具を用いて調整します。 - ・ドラム側のタップ穴はチェーンアタッチメント穴を基準に現物合わせで加工します。

4. ドラム内周に全内巻きの場合と、部分巻きの場合

- ・スプロケット歯形が特殊です。当社へお問合せください。

5. 横巻(水平駆動)に使用する場合

- ・3.項をご参照ください。

- ・内接の場合は、当社へお問合せください。

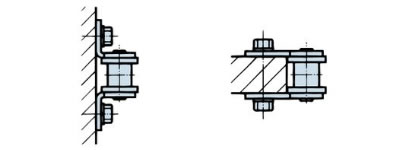

6. スプロケットの取付け

- ・チェーン式ピンギヤ用スプロケットをご使用ください。

- ・スプロケット歯側面に強い当たりが出ないように、スプロケットの取付軸の調整を行います。

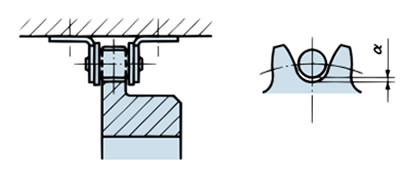

RSカーブドチェーンは、チェーンが横曲がりしているためスプロケットの歯側面と当たります。 - ・ローラとスプロケット歯底の遊びαは、右表の寸法以下とします。

ただし、歯底とローラが当たらないようにします。 - ・運転や環境条件により、運転中に上記遊びを確保できなくなる可能性がある場合は、

αを大きく設計した歯形が必要になります。当社にお問合せください。

| チェーンサイズ | α |

|---|---|

| RS80以下 | 1.0mm |

| RS100~RS180 | 1.5mm |

| RS200以上 | 2.0mm |