技術資料 ドライブチェーン チェーン選定について

選定に必要な計算式

計算式に使用する記号と単位

| 記号 | 説明 | SI単位 | {重力単位} |

|---|---|---|---|

| αb | 負荷の減速度 | m/s2 | m/s2 |

| αs | 負荷の加速度 | m/s2 | m/s2 |

| C | 軸間距離をリンク数で表わしたもの | - | - |

| C′ | 機長 | m | m |

| d | 減速機出力軸スプロケットのピッチ円直径 | mm | mm |

| d1 | 小スプロケットのピッチ円直径 | mm | mm |

| d2 | 大スプロケットのピッチ円直径 | mm | mm |

| D | ドラム外径 | mm | mm |

| Fb | 減速時のチェーン張力 | kN | kgf |

| F'b | 減速時の補正チェーン張力 | kN | kgf |

| FC | 台車駆動のチェーン張力 | kN | kgf |

| F'C | 台車駆動の補正チェーン張力 | kN | kgf |

| Fℓ | 負荷(実荷重)側トルクによるチェーン張力 | kN | kgf |

| F'ℓ | 負荷(実荷重)側トルクによる補正チェーン張力 | kN | kgf |

| Fm | 原動機定格出力(kW)によるチェーン張力 | kN | kgf |

| F'm | 原動機側からの補正チェーン張力 | kN | kgf |

| Fms | 原動機の始動トルクによるチェーン張力 | kN | kgf |

| F'ms | 原動機の始動トルクによる補正チェーン張力 | kN | kgf |

| Fmb | 原動機のブレーキトルクによるチェーン張力 | kN | kgf |

| F'mb | 原動機のブレーキトルクによる補正チェーン張力 | kN | kgf |

| FS | 加速時のチェーン張力 | kN | kgf |

| F'S | 加速時の補正チェーン張力 | kN | kgf |

| FW | 負荷(実荷重)によるチェーン張力 | kN | kgf |

| F'W | 負荷(実荷重)からの補正チェーン張力 | kN | kgf |

| f1 | ローラとレールの摩擦係数(潤滑あり0.14 潤滑なし0.21) | - | - |

| G | 標準重力加速度G = 9.80665m/S2 | - | - |

| i | 速比(例)1/30であればi = 30とする | - | - |

| Iℓ{GD2ℓ} | 負荷の原動機軸換算慣性モーメント | kg・m2 | kgf・m2 |

| Im{GD2m} | 原動機軸の慣性モーメント | kg・m2 | kgf・m2 |

| K | 衝撃係数 | - | - |

| Kn | 回転係数 | - | - |

| Ks | 使用係数 | - | - |

| Ku | アンバランス荷重係数 | - | - |

| Kv | ピンギヤ速度係数 | - | - |

| Kz | 歯数係数 | - | - |

| L | チェーン長さ(リンク数) | - | - |

| m | チェーンの単位質量{重量} | kg/m | kgf/m |

| M{W} | 負荷の質量{重量} | kg | kgf |

| n | チェーン速度を求めるときの小スプロケットの回転速度 | r/min | rpm |

| n1 | 原動機軸の回転速度 | r/min | rpm |

| n2 | 負荷軸の回転速度(従動軸の回転速度) | r/min | rpm |

| P | チェーンピッチ | mm | mm |

| R | 慣性比 | - | - |

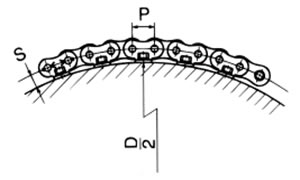

| S | RSアタッチメント付チェーンのアタッチメント高さ(ドラム取付面からチェーンピッチ中心までの距離) | mm | mm |

| tb | 減速時間 | s | s |

| tS | 加速時間 | s | s |

| Tb | 原動機のブレーキトルク | %(kN・m) | %(kgf・m) |

| Tmax | 原動機の最大(停動)トルク | %(kN・m) | %(kgf・m) |

| TS | 原動機の始動トルク | %(kN・m) | %(kgf・m) |

| Tℓ | 負荷トルク | kN・m | kgf・m |

| Tm | 作用トルク | kN・m | kgf・m |

| Tn | 原動機の定格トルク | kN・m | kgf・m |

| V | チェーン速度 | m/min | m/min |

| Vℓ | 負荷の速度 | m/min | m/min |

| Z | 大スプロケットの歯数 | - | - |

| Z′ | 小スプロケットの歯数 | - | - |

| ω | 原動機軸の角速度 | rad/min | rad/min |

| ωb | 原動機軸の角減速度 | rad/s2 | rad/s2 |

| ωS | 原動機軸の角加速度 | rad/s2 | rad/s2 |

計算式

- 1. チェーンを含む伝達効率η = 1として、すべての選定をしています。

- 2. 選定に使用する張力や伝動kWは表の13項、14項で計算した値を使用してください。

| 項目 | SI単位 | {重力単位} |

|---|---|---|

|

1. チェーン長さ(リンク数):L |

2軸巻掛け伝動のとき

|

|

|

ピンギヤ駆動 |

ドラム外周にアタッチメント付チェーンをドラム外巻きで使用する場合 L = 180° tan-1 P D + 2S

|

|

|

2. チェーン速度:V |

V = P × Z' × n 1000 (m/min) |

|

|

3. 原動機定格出力 (kW), 定格回転速度によるチェーン張力:Fm |

Fm = 60 × kW V (kN) |

Fm = 6120 × kW V (kgf) |

|

4. 負荷の慣性モーメントI(GD2)を |

Iℓ = M × V 2πn1 2 (kg・m2) |

GD2ℓ = W × V πn1 2 (kgf・m2) |

|

5. 原動機の定格トルク:Tn |

Tn = 9.55 × kW n1 (kN・m) |

Tn = 974 × kW n1 (kgf・m) |

|

6. 作用トルク:Tm |

Tm =

Ts(%) + Tmax(%)

2 × 100

× Tn (kN・m) |

Tm =

Ts(%) + Tmax(%)

2 × 100

× Tn (kgf・m) |

|

7. 始動トルクによるチェーン張力:Fms |

Fms =

Ts(%) × i

{d/(2 × 1000)} × 100

× Tn × 1(kN) |

Fms =

Ts(%) × i

{d/(2 × 1000)} × 100

× Tn × 1(kgf) |

|

ブレーキトルクによるチェーン張力:Fms |

Fmb =

Tb(%) × i

{d/(2 × 1000)} × 100

× Tn × 1.2*(kN) *は定数 |

Fmb =

Tb(%) × i

{d/(2 × 1000)} × 100

× Tn × 1.2*(kgf) *は定数 |

8. 加速時間:ts |

ts = (Im + Iℓ) × n1 9550 × (Tm - Tℓ) (s) |

ts = (GD2m + GD2ℓ) × n1 375 × (Tm - Tℓ) (s) |

9. 減速時間:tb ±:吊下げ荷重などのマイナス負荷のときは |

tb = (Im + Iℓ) × n1 9550 × (Tb ± Tℓ) (s) |

tb = (GD2m + GD2ℓ) × n1 375 × (Tb ± Tℓ) (s) |

10. 加速度

直線加速を想定しています。 そうでなければ最大加速度で計算してください。 |

直線運動(負荷の加速度) αs = Vℓ ts × 60 回転運動(原動機軸の角速度) ω = 2π × n1 回転運動(原動機軸の角加速度) ωs = ω ts × 60 |

|

11. 減速度

直線加速を想定しています。 そうでなければ最大減速度で計算してください。 |

直線運動(負荷の減速度) αb = Vℓ tb × 60 回転運動(原動機軸の角速度) ω = 2π × n1 回転運動(原動機軸の角減速度) ωb = ω tb × 60 |

|

12. 加速時のチェーン張力:Fs |

直線運動 Fs = M × αs 1000 + Fw 回転運動 Fs = Iℓ × ωs × i 1000 × d 2 × 1000 + Fw |

直線運動 Fs = M × αs G + Fw 回転運動 Fs = GD2ℓ/4 × ωs × i d 2 × 1000 × G + Fw |

減速時のチェーン張力:Fb |

直線運動 Fb = M × αb 1000 + Fw 回転運動 Fb = Iℓ × ωb × i 1000 × d 2 × 1000 + Fw |

直線運動 Fb = M × αb G + Fw 回転運動 Fb = GD2ℓ/4 × ωb × i d 2 × 1000 × G + Fw |

13. 補正 kW(一般選定のとき) |

補正 kW = 原動機定格 kW × Ks (kW) | |

14. 補正チェーン張力 |

||

原動機からの補正チェーン張力:F'm |

F'm = Fm × Ks × Kn × Kz (kN) {kgf} | |

始動トルクからの補正チェーン張力:F'ms |

F'ms = Fms × K × Kn × Kz (kN) {kgf} | |

停動トルクからの補正チェーン張力:F'mb |

F'mb = Fmb × K × Kn × Kz (kN) {kgf} | |

台車駆動の補正チェーン張力:F'c |

F'c = Fc × Ks × Kn × Kz (kN) {kgf} | |

加速時の補正チェーン張力:F's |

F's = Fs × Kn × Kz (kN) {kgf} | |

減速時の補正チェーン張力:F'b |

F'b = Fb × Kn × Kz (kN) {kgf} | |

負荷からの補正チェーン張力:F'w |

F'w = M × Ks × Kn × Kz × G 1000 (kN) |

F′w = W (またはFw) × Ks × Kn × Kz(kgf) |

|

質量M{重量W}が不明のときは、原動機の定格トルクTnより、軸トルクT = Tn × i (kN・m){kgf・m}を求め、 |

||

15. 慣性比:R |

R = Iℓ Im |

R = GD2ℓ GD2m |

16. 慣性モーメント(I)とはずみ車効果(GD2)の換算 |

1kg・m2...(I) | 4kgf・m2...(GD2) |

上記計算式でのチェーン張力はすべてチェーン1本で使用するときの張力です。

2本以上のチェーンを使用するときは、アンバランス荷重係数 Ku(表4)を乗じて1本当りのチェーン張力を算出します。

アンバランス荷重係数 Ku

吊下げ用、台車駆動などでチェーン2本または4本で吊下げ、台車けん引するときは、チェーンの作用張力が均等になりません。

左右のアンバランスの目安として下記アンバランス荷重係数Kuを乗じて1本当りのチェーン作用張力を求めるときに使用します。

(例) 4本吊りでの1本当りのアンバランス荷重係数

Ku = 0.6 × 0.6 = 0.36

| 2本 | 0.6 |

|---|---|

| 4本 | 0.36 |