技術資料 タイミングベルト・タイミングプーリ 取扱

取扱説明(ロックプーリ® Cタイプ)

取扱説明

取付け

- 1)軸表面にゴミ・汚れなどがあれば布などできれいにふき取ってください。プーリハブおよびクランプカラーの接触面もゴミ・汚れなどがあればきれいにふき取ってください。

- 2)締付ボルトの座面およびねじ面にはあらかじめ固形潤滑剤を塗布していますので、ふき取りやオイルまたはグリース塗布などは行わないようにしてください。

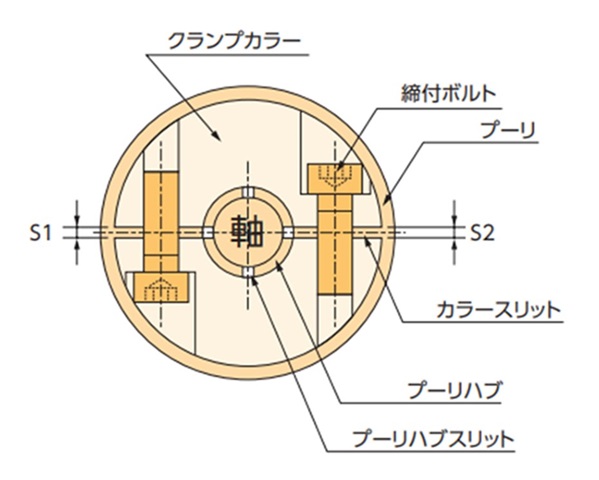

- 3)プーリのハブ部にスリットが4ヶ所設けられているものについては、クランプカラーはそのスリット部とカラーのスリット部とがほぼ同一の位置になるようセットしてください。

- 4)位置決めを確認しましたら左右のボルトを正規の締付トルク(下表に示すボルト締付トルクMA)の1/2程度で交互に締付けてください。その際、左右のカラースリットの巾S1、S2が目視にてほぼ均一になるよう調整しながら締付けを行ってください。

- 5)正規の締付けトルクMAで左右のボルトを交互に締付けてください。ボルトが回転しなくなったら取付けは完了です。

取付け時の注意

- ・締付ボルトの締付けには必ずトルクレンチを使用してください。締付要領や締付トルクMAを守って締付けてください。トルクレンチ以外の使用や手締めによる作業は不正確であり、スリップや変形などの事故の原因となります。

- ・正規の締付トルク以上のボルトの締付けはボルトの破損の原因となります。また正規の締付トルク以下でのボルトの締付けはボルトの緩みの原因となります。ボルトの締付けは、必ず正規の締付トルクMAを守って行ってください。

- ・締付ボルトは、本品に備わっている以外のボルトを絶対に使用しないでください。ボルトの破損など事故の原因となります。紛失・取替えなどにより、新しくボルトが必要な場合は当社までご連絡ください。

- ・軸径公差および表面粗さ:軸径の公差h8、軸表面粗さはRa3.2としてください。

表1 ボルト締付けトルク一覧表

| クランプカラー枠番 | ボルトサイズ | ボルト締付トルク MA | |

|---|---|---|---|

| C1, C2 | M4 | 3.8N・m | 0.39kgf・m |

| C3, C4, C5 | M5 | 7.5N・m | 0.77kgf・m |

| C6 | M6 | 12.6N・m | 1.3kgf・m |

取外し

プーリと軸にトルクやスラストなどの荷重がかかっていないことを確認した後、左右のボルトを緩めて取外してください。