技術資料 直動機器 リニパワージャッキ 取扱

据付

ジャッキ取付面

ジャッキの取付面には、防錆目的で塗装しています。取付面に塗装が不要な場合は当社までお問合せください。

据付方向

押上げ荷重には押上用、吊下げ荷重には吊下用をご使用いただくとより安全です。

また、ジャッキは開放構造ですので、グリース、グリースの分離油が飛散、落下するおそれがあります。グリース受け等をご用意ください。特に、吊下用をご使用の場合は、グリースがネジ軸をつたわって落ちるおそれがあります。

据付方向

ジャッキのギヤケースにある4ヵ所の取付穴を利用し、取付ボルトにて固定ください。 (取付ボルトは付属していません。)

ジャッキの取付ボルトサイズは表1をご参照ください。取付ボルトは、通常の場合強度区分8.8または10.9のものをご使用ください。

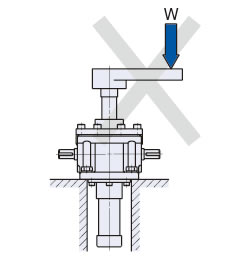

図1のように取付ボルト自体に荷重がかかる場合には強度区分10.9以上のものをご使用ください。

表1 取付ボルトサイズ

| 形番 | 取付穴 | ボルトサイズ |

|---|---|---|

| JW002 | 4-Φ7 | M6 |

| JW005 | 4-Φ7 | M6 |

| JW010 | 4-Φ9 | M8 |

| JW025 | 4-Φ11 | M10 |

| JW050 | 4-Φ18 | M16 |

| JW100 | 4-Φ22 | M20 |

| JW150 | 4-Φ22 | M20 |

| JW200 | 4-Φ26 | M24 |

| JW300 | 4-Φ33 | M30 |

| JW500 | 4-Φ42 | M39 |

| JW750 | 4-Φ42 | M39 |

| JW1000 | 6-Φ42 | M39 |

図1

※ジャッキの自重とともに吊下げ荷重が取付ボルトに引張荷重としてかかります。

モータ、減速機との連結

ジャッキ本体のほかモータ、減速機等の据付時には、適正な据付けが行えるよう、最大荷重が加わっても据付時の心出し精度がくるわない安全率を見込んだ強固な架台をご用意ください。

また、入力軸に接続される伝動軸等の心出しを確実に行ってください。(図2)

フローティングシャフトで駆動する場合には、回転速度により振動が発生するなど作動不良の原因になりますので、シャフトの剛性、カップリングのバックラッシを十分検討ください。

図2

先端金具の取付

ネジ軸端に先端金具を取付ける場合には、軸端のネジ部に緩み止めを施してください。

ネジ軸には回転トルクがはたらき、先端金具が抜落ちますので下記内容を実施ください。

[ネジ緩み止め接着剤を塗布]

ネジの緩み止めには、下記の銘柄のもの、または相当品をご使用ください。

接着剤塗布時には各メーカの取扱注意などを遵守ください。

ネジ緩み止め接着剤

| メーカ | 銘柄 |

|---|---|

| 日本ロックタイト株式会社 | #262、271 |

| スリーボンド株式会社 | #1307N |

[止めネジで固定]

先端金具を締込んだ後、緩み止めとして付属の止めネジ(六角穴付ボルト)で固定してください。

ネジ軸の回転防止

ネジ軸(トラベリングナット仕様の場合はナット)には推力に伴って回転力が生じますので、回転防止が必要です。基本容量時のネジ軸回転トルクは各タイプの基本仕様一覧に記載しています。先端部をガイドしない状態で作動させる場合や滑車やスプロケットをつけてロープやチェーン等を引張る場合には、回り止め仕様(記号M)をご使用ください。

JWH(ハイリードボールネジタイプ)の回り止め仕様は特形対応になりますので、当社へお問合せください。

ただし、トラベリングナット仕様は回り止め仕様の製作はできませんので、装置側で回り止め機構を設けてください。

リミットスイッチの設定

ストロークを調整するために設置するリミットスイッチは、ジャッキの惰行量を見込んで設定ください。

惰行量は、据付状態、運搬物重量によって変わりますので、最大の惰行量を見込んでください。また、万が一のことを考慮して、ストローク範囲内に機械的なストッパ等を設置ください。

位置検出ユニットの設定

オプションの位置検出ユニット(内部 LS、ポテンショメータ、ロータリエンコーダ)をご使用の場合には、工場出荷段階でのストローク調整等は行っていませんので、運転前には必ず調整を行ってください。ポテンショメータ、ロータリエンコーダ等のコントロールユニットは、入力軸の回転数を計測することによって種々の信号を出しますので、入力軸固定のままネジ軸を回転させますと設定がずれることになりますので、調整後はネジ軸(トラベリングナット仕様の場合はナット)を回転させないでください。

内部 LS の調整時には、ジャッキのストローク範囲を超えないように十分注意をしながら手動またはインチングにより作動させて設定ください。ストローク限界を超えますとネジ軸の脱落やジャバラの破損などを起こしますのでご注意ください。

ジャバラ付ジャッキの水平または傾斜使用

ジャバラ付ジャッキを水平または傾斜方向でのご使用(揺動を伴うご使用を含む)の場合は、ネジ軸がジャバラを噛み込んでジャバラを破損する、もしくはジャッキが不具合を発生するおそれがありますので特殊対応となります。

ジャバラ付ジャッキのX寸法(MIN値およびMAX値)が長くなる、あるいはジャバラ外径が大きくなる場合があります。

購入の際に寸法の確認が必要な場合は当社までお問合せください。

トラベリングナット仕様のジャバラ付は特形対応になりますので、当社へお問合せください。

注意事項

- ⚠ (1)基本容量49.0kN{5tf}以下のジャッキのネジカバーは硬質塩化ビニール製パイプを使用しています。落下のおそれがありますので、ネジカバーを利用しての吊上げ・吊下げ、運搬等は危険ですので絶対に行わないでください。

- ⚠ (2)使用ストロークに対し、ジャッキのストロークは余裕を見込んで選定、ご使用ください。ジャッキのストローク範囲以上に使用しますとネジ軸の脱落やジャッキの破損を招きます。JWM(台形ネジタイプ)はネジ軸に抜止めを設けていませんので、ストローク範囲を超えるとネジ軸は抜落ちます。JWB(ボールネジタイプ)、JWH(ハイリードボールネジタイプ)は抜止めを設けていますが、これは据付時の手動操作中にネジ軸が抜け落ちないようにするためのものです。据付時にはネジ軸が自重で回転・移動しないように考慮してください。抜落ちが避けられない場合は、回り止め仕様(回転防止機構付)をご使用ください。

- ⚠ (3)JWB(ボールネジタイプ)およびJWH(ハイリードボールネジタイプ)は荷重が作用している状態で、入力軸から手動操作をしないでください。荷重により入力軸が回され危険です。JWB(ボールネジタイプ)およびJWH(ハイリードボールネジタイプ)を垂直方向で使用される場合、効率が非常によい為、負荷によりジャッキが逆転するおそれがありますので、絶対に手動操作は行わないでください。

- ⚠ (4)いかなる場合も当て止めは行わないでください。当て止めを行いますとジャッキ内部に重大な損傷を起こします。

- (5)食品機械等で油気を嫌う装置には、グリースの飛散・落下に備えて、油受け等の損害防止装置を取付けてください。

- (6)ネジカバーやネジ軸を架台に通す穴は、ジャッキ据付面と架台との接触面積を大きくとれるようにできる限り小さな穴にしてください。

- (7)ジャッキに加わる荷重は、ジャッキのネジ軸方向と同軸上に作用するようにしてください。作用方向や位置が不適切ですと、ジャッキに曲げ荷重や横荷重が加わり破損のおそれがあります。(図3)

横荷重などが加わる場合は、ガイドを設けてジャッキが直接横荷重や曲げモーメントを受けないようにご配慮ください。

図3