技術資料 トップチェーン 選定

このページの後半では以下の選定例についても紹介しています。

(各項目をクリックすると本文にスクロールできます。)

プラスチックモジュラーチェーン(固定幅)の選定例

WT0700シリーズ選定例

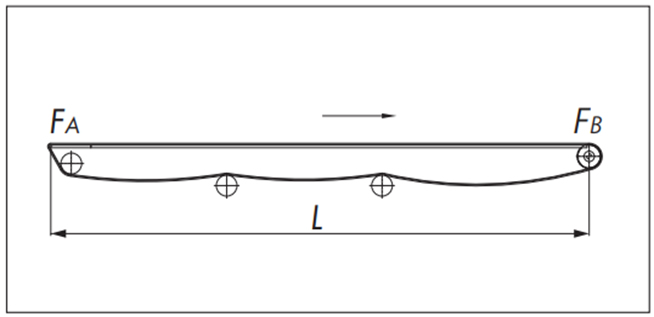

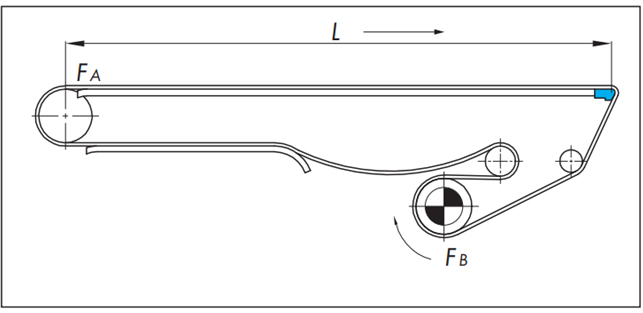

従動側ノーズバー

●計算式(SI単位:kN)

・戻り側張力

[A部張力:FA]

FA = m1・L・μ1・fn × 9.80665 × 10-3

・搬送側張力

[B部張力:FB]

FB = FA + {(m1 + m2) L・μ1 + m2・LS・μ2} × 9.80665 × 10-3

・チェーン張力

F = FB

※)搬送物のアキュームが無い場合は、LS = 0

●計算例(SI単位)

| 使用条件 | |

|---|---|

| チェーン形式 | WT0705-W300-LFG (m1=5.9×0.3=1.77kg/m) |

| チェーン幅 | 300mm |

| レイアウト | L=2m |

| チェーン速度 | V=15m/min |

| 搬送物 | アルミ缶500ml(実) |

| 搬送物質量(1m長さ当たり) | m2=139kg/m2(523g/個) ×0.3m=41.7kg/m |

| 走行レール | 超高分子量ポリエチレン (プラレール) |

| アキューム距離 | Ls=2m |

| 潤滑 | ドライ |

| 使用雰囲気温度 | 20℃ |

| チェーンと走行レールの動摩擦係数 | μ1=0.2 |

| チェーンと搬送物との動摩擦係数 | μ2=0.2 |

| ノーズバー係数 | fn=1.8 |

・戻り側張力

[A部張力:FA]

FA = 1.77 × 2 × 0.2 × 1.8 × 9.80665 × 10-3 = 0.0125kN

・搬送側張力

[B部張力:FB]

FB = 0.0125 + {(1.77 + 41.7) × 2 × 0.2 + 41.7 × 2 × 0.2} × 9.80665 × 10-3 = 0.35kN

・使用判定

最大許容張力≧FB'

チェーン幅1m当たりに換算する

FB' = 1000 × FB 300 = 1.17(kN/m)

能力線図より許容張力は2.5(kN/m)

2.5(kN/m)≧1.17(kN/m)

選定チェーンは使用可能です。

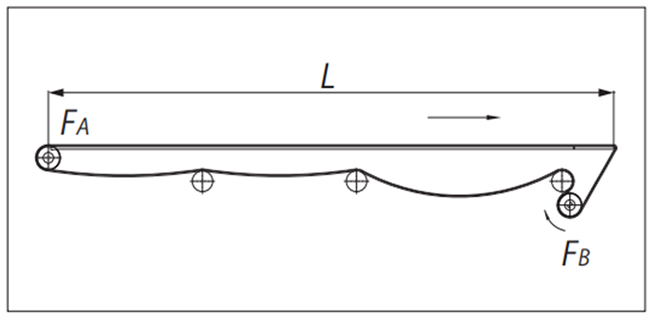

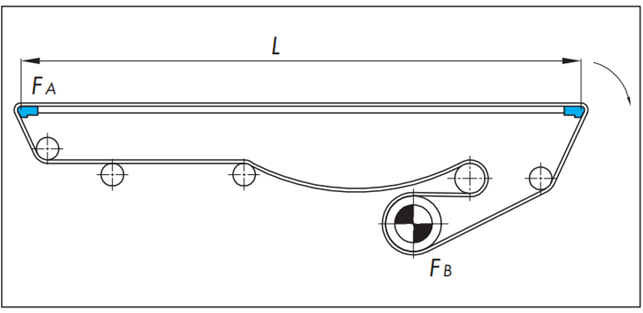

前方側ノーズバー

●計算式(SI単位:kN)

・戻り側張力

[A部張力:FA]

FA = 1.1m1・L・μ1 × 9.80665 × 10-3

・搬送側張力

[B部張力:FB]

FB= [FA + {(m1 + m2) L・μ1 + m2・LS・μ2} × 9.80665 × 10-3] × fn

・チェーン張力

F = FB

※)搬送物のアキュームが無い場合は、LS = 0

●計算例(SI単位)

| 使用条件 | |

|---|---|

| チェーン形式 | WT0705-W300-LFG (m1=5.9×0.3=1.77kg/m) |

| チェーン幅 | 300mm |

| レイアウト | L=2m |

| チェーン速度 | V=15m/min |

| 搬送物 | アルミ缶500ml(実) |

| 搬送物質量(1m長さ当たり) | m2=139kg/m2(523g/個) ×0.3m=41.7kg/m |

| 走行レール | 超高分子量ポリエチレン (プラレール) |

| アキューム距離 | Ls=2m |

| 潤滑 | ドライ |

| 使用雰囲気温度 | 20℃ |

| チェーンと走行レールの動摩擦係数 | μ1=0.2 |

| チェーンと搬送物との動摩擦係数 | μ2=0.2 |

| ノーズバー係数 | fn=1.8 |

・戻り側張力

[A部張力:FA]

FA = 1.1 × 1.77 × 2 × 0.2 × 9.80665 × 10-3 = 0.0077kN

・搬送側張力

[B部張力:FB]

FB = [0.0077 + {(1.77 + 41.7) × 2 × 0.2 + 41.7 × 2 × 0.2} × 9.80665 × 10-3] × 1.8 = 0.62kN

・使用判定

最大許容張力≧FB'

チェーン幅1m当たりに換算する

FB' = 1000 × FB 300 = 2.07(kN/m)

能力線図より許容張力は2.5(kN/m)

2.5(kN/m)≧2.07(kN/m)

選定チェーンは使用可能です。

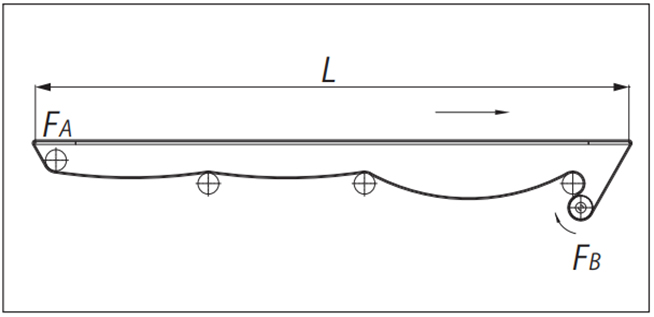

両端ノーズバー

●計算式(SI単位:kN)

・戻り側張力

[A部張力:FA]

FA = m1・L・μ1・fn × 9.80665 × 10-3

・搬送側張力

[B部張力:FB]

FB= [FA + {(m1 + m2) L・μ1 + m2・LS・μ2} × 9.80665 × 10-3] × fn

・チェーン張力

F = FB

※)搬送物のアキュームが無い場合は、LS = 0

●計算例(SI単位)

| 使用条件 | |

|---|---|

| チェーン形式 | WT0705-W300-LFG (m1=5.9×0.3=1.77kg/m) |

| チェーン幅 | 300mm |

| レイアウト | L=2m |

| チェーン速度 | V=15m/min |

| 搬送物 | アルミ缶500ml(実) |

| 搬送物質量(1m長さ当たり) | m2=139kg/m2(523g/個) ×0.3m=41.7kg/m |

| 走行レール | 超高分子量ポリエチレン (プラレール) |

| アキューム距離 | Ls=2m |

| 潤滑 | ドライ |

| 使用雰囲気温度 | 20℃ |

| チェーンと走行レールの動摩擦係数 | μ1=0.2 |

| チェーンと搬送物との動摩擦係数 | μ2=0.2 |

| ノーズバー係数 | fn=1.8 |

・戻り側張力

[A部張力:FA]

FA = 1.77 × 2 × 0.2 × 1.8 × 9.80665 × 10-3 = 0.0125kN

・搬送側張力

[B部張力:FB]

FB = [0.0125 + {(1.77 + 41.7) × 2 × 0.2 + 41.7 × 2 × 0.2} × 9.80665 × 10-3] × 1.8 = 0.63kN

・使用判定

最大許容張力≧FB'

チェーン幅1m当たりに換算する

FB' = 1000 × FB 300 = 2.1(kN/m)

能力線図より許容張力は2.5(kN/m)

2.5(kN/m)≧2.1(kN/m)

選定チェーンは使用可能です。

fn(ノーズバー係数)

| 潤滑状況 | ノーズバー係数 fn |

|---|---|

| 摺動タイプ | |

| ドライ | 1.8 |

| 石鹸水 | 1.35 |

WT1500シリーズ、WT1510シリーズ、BTN5形選定例

従動側ノーズバー

●計算式(SI単位:kN)

・戻り側張力

[A部張力:FA]

FA = m1・L・μ1・fn × 9.80665 × 10-3

・搬送側張力

[B部張力:FB]

FB = FA + {(m1 + m2) L・μ1 + m2・LS・μ2} × 9.80665 × 10-3

・チェーン張力

F = FB

※)搬送物のアキュームが無い場合は、LS = 0

●計算例(SI単位)

| 使用条件 | |

|---|---|

| チェーン形式 | WT1506-K30-ALF (m1=6.7×0.762=5.1kg/m) |

| チェーン幅 | 762mm |

| レイアウト | L=4m |

| チェーン速度 | V=15m/min |

| 搬送物 | アルミ缶500ml(実) |

| 搬送物質量(1m長さ当たり) | m2=139kg/m2(523g/個) ×0.762m=106kg/m |

| 走行レール | 超高分子量ポリエチレン (プラレール) |

| アキューム距離 | Ls=4m |

| 潤滑 | ドライ |

| 使用雰囲気温度 | 20℃ |

| チェーンと走行レールの動摩擦係数 | μ1=0.15 |

| チェーンと搬送物との動摩擦係数 | μ2=0.14 |

| ノーズバー係数 | fn=1.35(ベアリング・ローラタイプ) |

・戻り側張力

[A部張力:FA]

FA = 5.1 × 4 × 0.15 × 1.35 × 9.80665 × 10-3 = 0.04kN

・搬送側張力

[B部張力:FB]

FB = 0.04 + {(5.1 + 106) × 4 × 0.15 + 106 × 4 × 0.14} × 9.80665 × 10-3 = 1.28kN

・使用判定

最大許容張力≧FB'

チェーン幅1m当たりに換算する

FB' = 1000 × FB 762 = 1.68(kN/m)

能力線図より許容張力は10.5(kN/m)

10.5(kN/m)≧1.68(kN/m)

選定チェーンは使用可能です。

前方側ノーズバー

●計算式(SI単位:kN)

・戻り側張力

[A部張力:FA]

FA = 1.1m1・L・μ1 × 9.80665 × 10-3

・搬送側張力

[B部張力:FB]

FB= [FA + {(m1 + m2) L・μ1 + m2・LS・μ2} × 9.80665 × 10-3] × fn

・チェーン張力

F = FB

※)搬送物のアキュームが無い場合は、LS = 0

●計算例(SI単位)

| 使用条件 | |

|---|---|

| チェーン形式 | WT1506-K30-ALF (m1=6.7×0.762=5.1kg/m) |

| チェーン幅 | 762mm |

| レイアウト | L=4m |

| チェーン速度 | V=15m/min |

| 搬送物 | アルミ缶500ml(実) |

| 搬送物質量(1m長さ当たり) | m2=139kg/m2(523g/個) ×0.762m=106kg/m |

| 走行レール | 超高分子量ポリエチレン (プラレール) |

| アキューム距離 | Ls=4m |

| 潤滑 | ドライ |

| 使用雰囲気温度 | 20℃ |

| チェーンと走行レールの動摩擦係数 | μ1=0.15 |

| チェーンと搬送物との動摩擦係数 | μ2=0.14 |

| ノーズバー係数 | fn=1.35(ベアリング・ローラタイプ) |

・戻り側張力

[A部張力:FA]

FA = 1.1 × 5.1 × 4 × 0.15 × 9.80665 × 10-3 = 0.03kN

・搬送側張力

[B部張力:FB]

FB = [0.03 + {(5.1 + 106) × 4 × 0.15 + 106 × 4 × 0.14} × 9.80665 × 10-3] × 1.35 = 1.71kN

・使用判定

最大許容張力≧FB'

チェーン幅1m当たりに換算する

FB' = 1000 × FB 762 = 2.24(kN/m)

能力線図より許容張力は10.5(kN/m)

10.5(kN/m)≧2.24(kN/m)

選定チェーンは使用可能です。

両端ノーズバー

●計算式(SI単位:kN)

・戻り側張力

[A部張力:FA]

FA = m1・L・μ1・fn × 9.80665 × 10-3

・搬送側張力

[B部張力:FB]

FB= [FA + {(m1 + m2) L・μ1 + m2・LS・μ2} × 9.80665 × 10-3] × fn

・チェーン張力

F = FB

※)搬送物のアキュームが無い場合は、LS = 0

●計算例(SI単位)

| 使用条件 | |

|---|---|

| チェーン形式 | WT1506-K30-ALF (m1=6.7×0.762=5.1kg/m) |

| チェーン幅 | 762mm |

| レイアウト | L=4m |

| チェーン速度 | V=15m/min |

| 搬送物 | アルミ缶500ml(実) |

| 搬送物質量(1m長さ当たり) | m2=139kg/m2(523g/個) ×0.762m=106kg/m |

| 走行レール | 超高分子量ポリエチレン (プラレール) |

| アキューム距離 | Ls=4m |

| 潤滑 | ドライ |

| 使用雰囲気温度 | 20℃ |

| チェーンと走行レールの動摩擦係数 | μ1=0.15 |

| チェーンと搬送物との動摩擦係数 | μ2=0.14 |

| ノーズバー係数 | fn=1.35(ノーズバー・ローラタイプ) |

・戻り側張力

[A部張力:FA]

FA = 5.1 × 4 × 0.15 × 1.35 × 9.80665 × 10-3 = 0.04kN

・搬送側張力

[B部張力:FB]

FB = [0.04 + {(5.1 + 106) × 4 × 0.15 + 106 × 4 × 0.14} × 9.80665 × 10-3] × 1.35 = 1.72kN

・使用判定

最大許容張力≧FB'

チェーン幅1m当たりに換算する

FB' = 1000 × FB 762 = 2.26(kN/m)

能力線図より許容張力は10.5(kN/m)

10.5(kN/m)≧2.26(kN/m)

選定チェーンは使用可能です。

fn(ノーズバー係数)

| 潤滑状況 | ノーズバー係数 fn | |

|---|---|---|

| 摺動タイプ | ベアリング・ローラタイプ | |

| ドライ | 1.8 | 1.35 |

| 石鹸水 | 1.35 | |

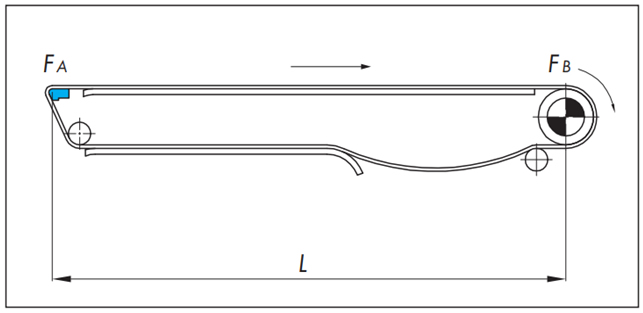

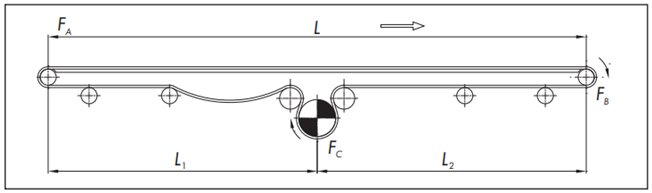

WT2525VG-K形選定例

正逆底部駆動の選定例

●計算式(SI単位:kN)

・戻り側張力(従動側)

[A部張力:FA]

FA = 1.1m1・L1・μ1 × 9.80665 × 10-3

・搬送側張力

[B部張力:FB]

FB = 1.1{FA + (m1 + m2) × L・μ1 × 9.80665 × 10-3}

・戻り側張力(駆動側)

[C部張力:FC]

FC = FB + m1・L2・μ1 × 9.80665 × 10-3

・チェーン張力

F = FC

●計算例(SI単位)

| 使用条件 | |

|---|---|

| チェーン形式 | WT2525VG-K36-G (m1=9.5×0.9144=8.7kg/m) |

| チェーン幅 | 914.4mm |

| レイアウト | L=10m, L1=6m, L2=4m |

| チェーン速度 | V=10m/min |

| 搬送物 | 段ボールシート 900mm×1800mm×5mm 106.4kg/m2=861.8g/枚×200枚(高さ1m) |

| 搬送物質量(1m長さ当たり) | m2=106.4kg/m2×0.9144m =97.3kg/m |

| 走行レール | 超高分子量ポリエチレン (プラレール) |

| 潤滑 | ドライ |

| 使用雰囲気温度 | 20℃ |

| チェーンと走行レールの動摩擦係数 | μ1=0.25 |

・戻り側張力(従動側)

[A部張力:FA]

FA = 1.1 × 8.7 × 6 × 0.25 × 9.80665 × 10-3 = 0.14kN

・搬送側張力

[B部張力:FB]

FB = 1.1 {0.14 + (8.7 + 97.3) × 10 × 0.25 × 9.80665 × 10-3} = 3.0kN

・戻り側張力(駆動側)

[C部張力:FC]

FC = 3.0 + 8.7 × 4 × 0.25 × 9.80665 × 10-3 = 3.09kN

・使用判定

最大許容張力≧FB'

チェーン幅1m当たりに換算する

FB' = 1000 × FB 914.4 = 3.34(kN/m)

能力線図より許容張力は12.8(kN/m)

12.8(kN/m)≧3.34(kN/m)

選定チェーンは使用可能です。