技術資料 クラッチ 取扱

MAシリーズ 取扱注意

- 1. 軸径はh6、またはh7を推奨します。

- 2. キーは必ず平行キーを使用し、キーの天井を利かすことは、絶対に避けてください。JIS B1301-1996(新JIS)平行キー(普通形)をご使用ください。

- 3. 軸へはめ込む際は、内輪端面に力を加えて取付けてください。外輪をたたくことは絶対に避けてください。

- 4. ピッチングマシンに使用する場合、アーム軸にはバランスウエイトを取り付けてアームとバランスをとってください。アンバランスですと大きな振動荷重を発生することがあります。

- 5. トルクアームの固定部には、ゴム等の緩衝材を用いて振動荷重を吸収できるようにしてください。

- 6. 取付参考図、使用方法は下記を参照ください。

- 7. 潤滑およびメンテナンスについてはこちらを参照ください。

反復衝撃荷重をともなうバックストップ

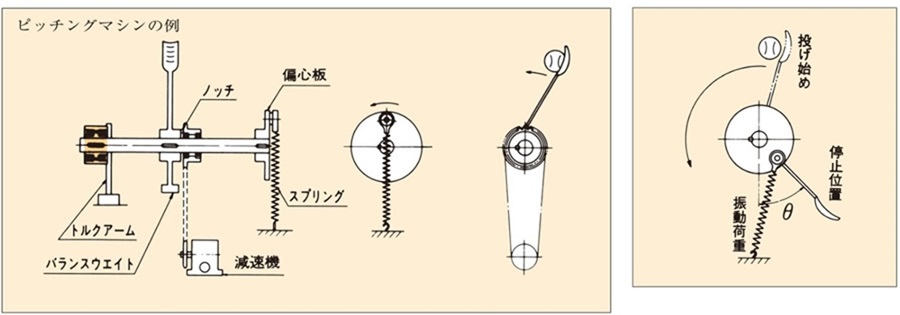

スプリングの反力など、瞬間的で衝撃的な振動荷重が反復してかかる逆転防止の使用法です。テニスマシンや、ピッチングマシンなどに使用されるものが、その代表的な例です。

減速モータによって常時回転しているスプロケット(ベアリング入り)の側面にはツメがあり、アーム(軸にキー止め)のボス端面のツメに当たってアームを押し上げます。

偏心板(軸にキー止め)に一端を取付けられたスプリングは、アーム軸の回転と共に伸ばされて行き、上死点を過ぎると急激に収縮します。このとき、アームはボールを投げ出します。

投げ終わった後もアームはその慣性により、下死点を過ぎ、スプリングを伸ばしながらある角度(θ)まで回転します。この間カムクラッチは空転を続けています。

θ度まで回転したアームは、スプリングの収縮力により、急激に逆転しようとしますが、カムクラッチがかみ合ってその逆転を防ぎます。

このときに生じる逆転トルクは、衝撃的な振動トルクです。これが反復荷重をともなうバックストップの荷重特性です。

注意点

アーム軸には、バランスウエイトを取付けて、動バランスをとってください。アンバランスのままですと、カムクラッチがかみ合う時に過度の振動が発生します。逆転トルク作用時の衝撃を最小にするために下記のことに留意ください。

- (1)トルクアーム先端をフレームに固定する部分には、振動荷重を吸収できるようにゴムなどの緩衝材を入れてください。

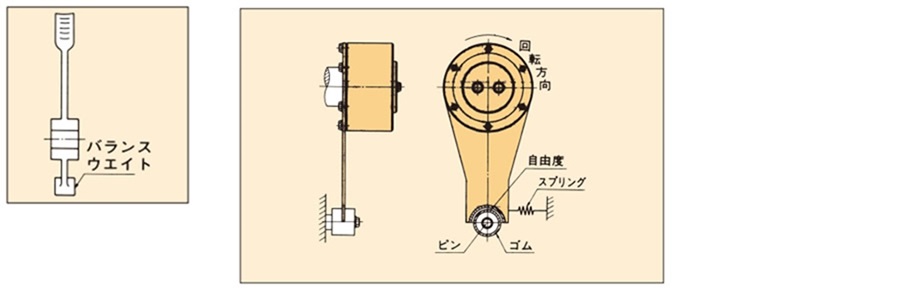

- (2)トルクアームの先端は、ボルトなどで完全固定せずに自由度を持たせてください。完全固定すると、カムクラッチ内にこじれが生じ損傷の原因になります。

- (3)トルクアーム先端の逆転トルクを受ける面と、緩衝材とのクリアランスを常に最小限に保つために、トルクアームに弱いスプリングなどにより逆転方向のモーメントを与えてください。