技術資料 クラッチ 取扱

LDシリーズ 取扱注意

- 1. 外輪に取付けるプーリなどの内径公差はH6、またはH7を推奨します。

- 2. カム&ローラ構造になっているので、ローラタイプのベアリング内蔵形です。内輪を抜き差しする時には、ローラが脱落しないよう静かに行ってください。

- 3. 軸への取付けは、内輪端面に力を掛けて静かに入れてください。この時、外輪から抜け落ちないよう注意してください。

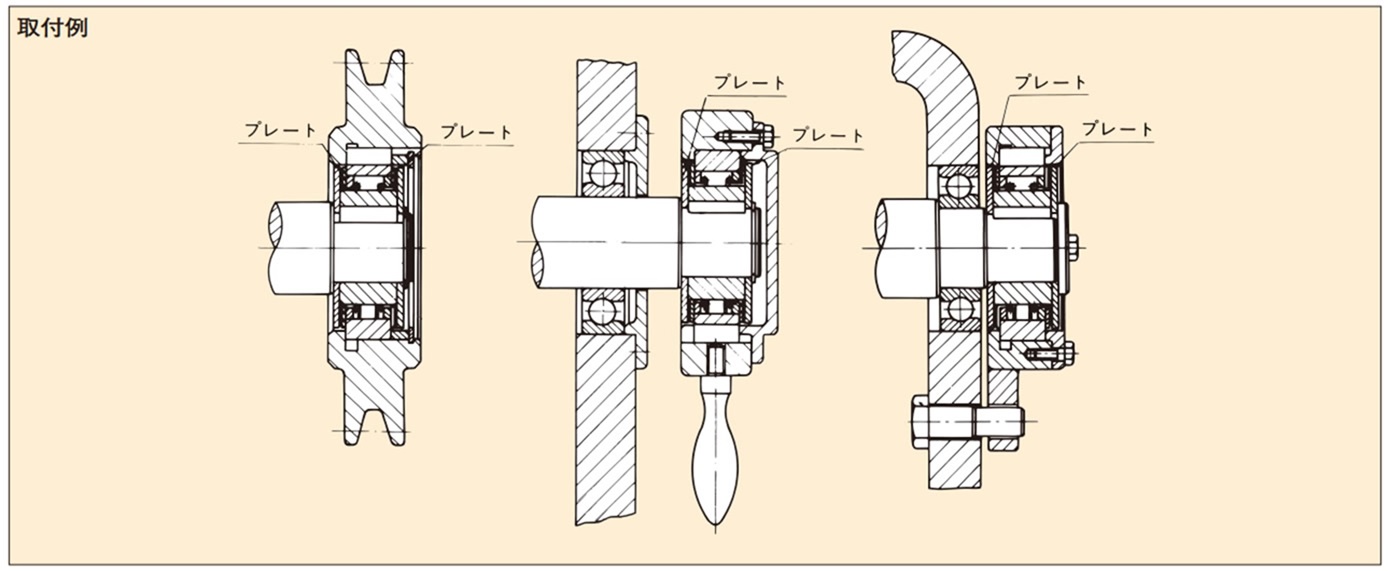

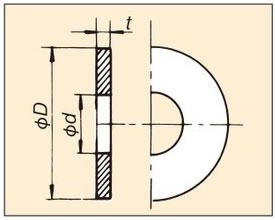

- 4. 外輪の左右への移動を止める、プレート(寸法はこちら)を製作して取付けてください。プレートを取付けないと、カムクラッチ外輪は左右に抜けます。

- 5. プレートとスラストメタルの間には、グリースを塗布してください。(取付例参照)

- 6. カムクラッチにスラスト荷重がかかる場合は、別途スラスト荷重を受けるものを設けてください。

- 7. 空転中に許容値以上のラジアル荷重が掛かる場合は、両側にベアリングを組込んでください。

- 8. カムクラッチに組込むベアリングは、製品ページの寸法表の中にカムクラッチ外径と、同一外径のベアリングが記載してあります。

- 9. キーは、JIS B1301-1959(旧JIS)平行キー2種をご使用ください。外輪のキー寸法は、JISで規定している軸径とキーの関係通りにはなっていませんので、ご注意ください。

- 10. 潤滑およびメンテナンスについてはこちらを参照ください。

×

(ドラッグで移動できます)

プレート推奨寸法

| サイズ | t | Φd | ΦD |

|---|---|---|---|

| LD04 | 2 | 10 | 40 |

| LD05 | 2 | 14 | 45 |

| LD06 | 3 | 20 | 52 |

| LD07 | 3 | 25 | 62 |

| LD08 | 3 | 30 | 70 |