技術資料 クラッチ 取扱

BSシリーズ 取扱注意

- 1.コンベヤ、ポンプなどの低速軸逆転防止専用カムクラッチです。

- 2.潤滑方式と防塵対策

BS30~BS135 BS160~BS350 潤滑仕様 グリース封入済です。

給脂は不要です。グリース潤滑タイプで1回/年のグリース交換で十分です。 防塵対策 ・ダブルリップオイルシール ・防塵板

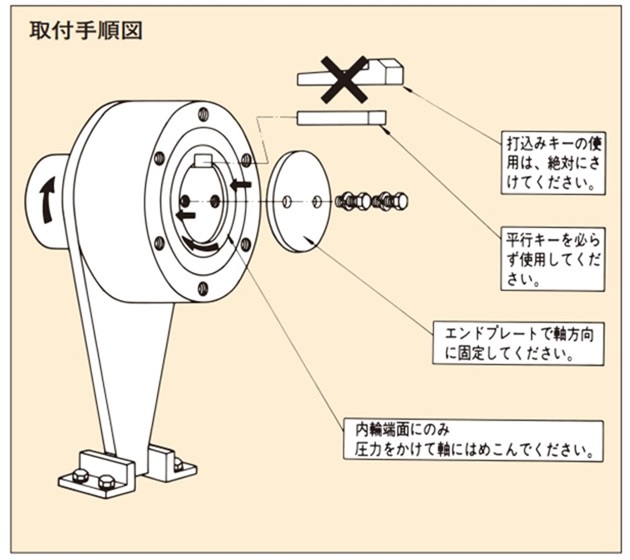

・ダブルリップオイルシール - 3. 取付前に、BSカムクラッチの内輪回転方向(内輪端面の矢印)が、コンベヤの回転方向と同一であることを、必ず確認してください。

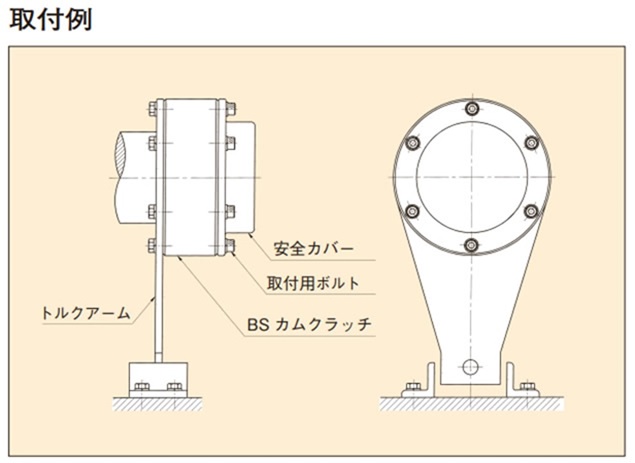

- 4. トルクアームは、強度区分10.9以上の強度のボルトでBSカムクラッチ本体にしっかりと取付てください。なお、トルクアームの外輪端面と接する面は、ボルト締めにより十分な摩擦力が得られるよう、ごみなどの付着がなく平面であることを確認してください。

- 5. 軸径公差はh7、またはh8を推奨します。

- 6. BSカムクラッチを軸へはめ込む際は、必ず内輪端面に力をかけてください。鉄ハンマーで直接内輪端面をたたいたり、外輪やオイルシール、および防塵板(グリスキリ)に力をかけることは絶対に避けてください。

- 7. 軸への取付けには必ず平行キーを使用し、エンドプレートで固定してください。打込みキーなどでキーの天井を利かすことは絶対に避けてください。カムクラッチ損傷の原因になります。

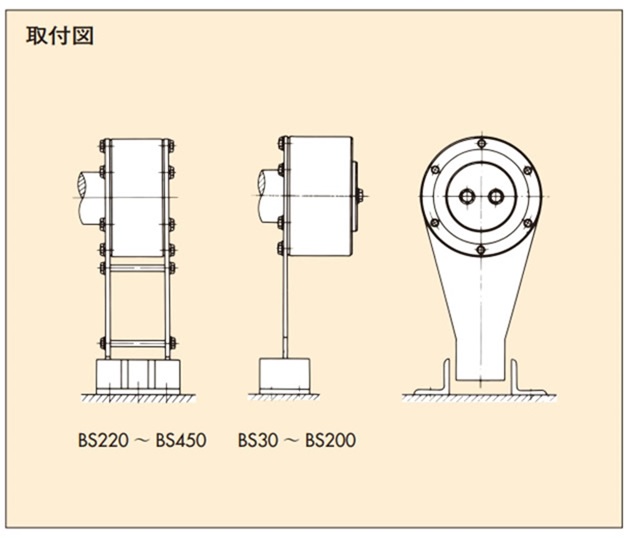

- 8. トルクアームの先端は、軸の回転中に軸方向にある程度揺れ動きます。トルクアームの先端は回転方向にのみ回り止めをし、軸方向には充分の自由度をとって、前記軸方向のゆれを許容してください。(取付図参照)トルクアーム先端を完全に固定しますと、カムクラッチ内部にコジレが生じ、損傷の原因になります。

- 9. BS30~BS200のトルクアームは、片側一枚で充分ですが、BS220~BS450については、両側アームとし、力点がどちら側にも片寄らず中央に来るようにしてください。

- 10. BSカムクラッチ専用トルクアームおよび安全カバーも標準化していますのでご利用ください。

- 11. 潤滑およびメンテナンスについてはこちらを参照ください。

BSシリーズ 安全カバー 取扱注意

- 1. BSカムクラッチへの取付けに際して、付属の六角穴付ボルトとバネ座金にて確実に取付けてください。

- 2. 安全カバーはトルクアームの反対側に取付けてください。

- 3. 詳細は取扱説明書をご参照ください。

- 4. 本カバーは安全カバー専用ですので、オイルリザーバとしてはご使用できません。