技術資料 ドライブチェーン ローラチェーンの取扱

ローラチェーンの継ぎ方、切り方は動画でもご覧になれます。

1. ローラチェーンの切り方

ローラチェーンは、必要な長さに切断する作業が必要になります。

1.1 チェーンバイスとパンチを使用する方法

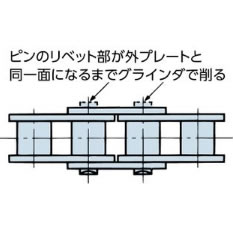

- 1. 本体ピン形式がRPのローラチェーンは、外リンクの2本のピンの一端(同じ側)を、プレートと同一面になるまでグラインダで削り落します。

グラインダ作業時は、チェーンのオーバヒートを避けてください。

プラコンビチェーンに締鋲はありません。削り落とす必要もありません。

RS08B-1~RS16B-1は、簡易切継ぎ仕様のピンを採用しています。ピン締鋲部を削り落とす必要はありません。 - 2. 本体ピン形式がCPのローラチェーンは割りピンなどの止め部品を抜きます。

図1. リベット形ローラチェーン

図2. ピンの端部を削る

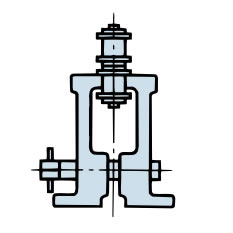

- 3. ローラチェーンをチェーンバイスの溝に通し、分解する箇所のローラをチェーンバイスの口金で軽く締め付けます。

プラコンビチェーンとラムダチェーンは1.3項・1.4項により行います。

スーパチェーンの多列の場合は、最下端のローラをチェーンバイスの口金に通します。図3. チェーンバイスにローラチェーンをセット

スーパチェーンのセット

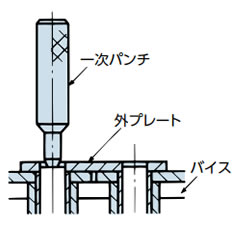

- 4. ローラチェーンのサイズに合った一次パンチを、削ったピンの頭に当て、一次パンチの頭をハンマでたたきます。

この際、外リンクの一対のピンが平行に抜けるように交互にたたきます。外プレートからピンが抜ける直前まで行います。図4. 一次パンチでピンをたたく

- 5. 二次パンチとハンマを用いて、外プレートから一対のピンを抜きます。

1.2 チェーンスクリュを使用する場合

- 1. 本体ピン形式がRPのローラチェーンは、外リンクの2本のピンの一端(同じ側)をグラインダで削り落します(1.1項と同じ要領)。

本体ピン形式がCPのローラチェーンは、割りピンなどの止め部品を抜きます。 - 2. ピンは同一の外リンクの2本のピンを抜きます。

図5. チェーンスクリュによる切り方

1.3 プラコンビチェーンの切り方

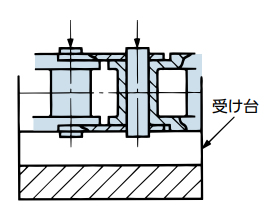

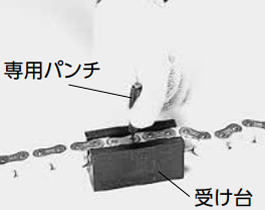

- 1. チェーンの外プレートを受け台で受け、ピンの頭を専用パンチで押さえて、ハンマでパンチの頭を軽くたたきます。

- 2. 内リンクに大きな力をかけて破損しないようにたたきます。

図6. プラコンビチェーンを受け台にセット

図7. プラコンビチェーンの分解

1.4 ラムダチェーンの切り方

- 1. 本体ピン形式がRPのローラチェーンは、外リンクの2本のピンの一端(同じ側)をグラインダで削り落とします(1.1項と同じ要領)。

本体ピン形式がCPのローラチェーンは、割りピンなどの止め部品を抜きます。 - 2. ラムダチェーン用切断工具の受け台と専用パンチを使用して切ります。切り方の要領は、1.1項のとおりです。ただし、バイスの代りに専用受け台を使用します。

- 3. パンチでピンを抜くときは、交互に軽くたたいて抜きます。

⚠切断時のご注意

- 1. 本体ピン形式がRPのピンの一端は、リベット部分を必ず削り落とす必要があります。そのまま抜くと、かえって手間がかかったり、チェーンをいためます。

- 2. チェーンスクリュは、ローラチェーンの分解専用工具です。チェーンを装置から外さずにローラチェーンを分解することができます。

ローラチェーンの自重を前もって支持して、ローラチェーン切断時の落下の防止を行なってください。 - 3. ピンを抜いた部分のブシュが抜けていないか、変形していないかをご確認ください。ブシュの抜けや部品の変形を確認したときは、その部分は使わないでください。

- 4. 取外した部品は再使用しないでください。

2. ローラチェーンの継ぎ方

2.1 スプロケットの歯の部分で継ぐ場合

ローラチェーンを連結するときは、スプロケットの歯を利用すると便利です。下記の要領で行います。

- 1. ローラチェーンをスプロケットに巻き付けて、ローラチェーンの両端がスプロケットにかかるようにします。

- 2. 継手リンクを継ぎ目に挿入します。

- 3. 継手プレートを入れて、次にクリップ、割りピン、またはスプリングピンなど止め部品で止めます。

- 4. F形継手リンクのときは、継手プレートをハンマで軽くたたき、所定の位置まで挿入します。その後にスプリングピンなど止め部品で止めます。

- 5. スプロケットの歯先をハンマ作業などで打ちつけないように、保護を行います。

図8. スプロケット部で継ぐ

2.2 軸間で継ぐ場合

レイアウトの関係でスプロケットの歯が利用できないときの方法です。

- 1. ローラチェーンをスプロケットに巻き付けて、ローラチェーンの両端をチェーンプーラ(アクセサリの項参照)またはワイヤなどで引き寄せます。

- 2. 継手リンクを継ぎ目に挿入します。

- 3. 継手プレートを入れて、クリップ、割りピン、またはスプリングピンなど止め部品で止めます。

図9. 軸間で継ぐ

2.3 クリップ・割りピン

1. クリップ

クリップは、RS60以下のローラチェーンの継手リンクで主に使用されています。

連結のときには、ピンに継手リンクプレートを挿入後、クリップを継手リンクの2本のピンの溝に確実に挿入します。

クリップを拡げ過ぎると、正しく挿入できず脱落します。

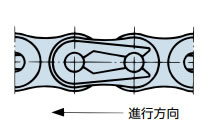

クリップの取付方向は、一般にローラチェーンの進行方向に対して図10のようにします。

図10. クリップの取付方向

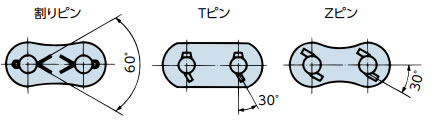

2. 割りピン

耐環境ドライブチェーンや特殊ドライブチェーンの一部を除き、使用されている割りピンは、熱処理を行っています。

割りピンの開き角度は60°程度にします。割りピンの再使用や市販の割りピンは使用しないでください。

図11. 止め部品の取付け

RSローラチェーン割りピン寸法表(ローラチェーン専用となります)

| サイズ | 割りピン称呼寸法 |

|---|---|

| RS35 | 1 × 6 |

| RS40 | 1 × 6 |

| RS50 | 1.6 × 8 |

| RS60 | 2 × 10 |

| RS80 | 2.5 × 14 |

| サイズ | 割りピン称呼寸法 |

|---|---|

| RS100 | 2.5 × 20 |

| RS120 | 3 × 23 |

| RS140・RS160 | 4 × 24.5 |

| RS180 | 5 × 32 |

| RS200 | 5 × 37 |

注)RS240に割りピンの設定がありません。

⚠連結時のご注意

- 1. 出来る限りオフセットリンクの使用を避けてください。軸間距離の調整、またはアイドラを用いてたるみを調整してください。

- 2. 摩耗伸びを起こしたチェーンのリンク切り詰めによるチェーン長さ調整は、避けてください。

- 3. F形継手リンクなど、ピンと継手プレートの穴がしまりばめの継手リンクは、プレートの穴を大きくしたり、ピン径を細くするとチェーンの強度が低下します。

追加工は行わないでください。 - 4. 一度外した外プレートは取外しにより強度が低下します。再使用はしないでください。

- 5. 継手リンクやオフセットリンクなどの単体品は、通常、防錆油のみ塗布しています。本体に組込む際は、ピンやブシュ穴の表面へ給油を行ってください。