技術資料 ドライブチェーン ローラチェーンの取扱

3.ローラチェーンの潤滑

ローラチェーン伝動において、潤滑は非常に重要です。特に、チェーンの使用される条件が、過酷になればなる程、潤滑の重要性が高まります。

潤滑が不完全では、高度に設定された伝動装置であっても到底寿命を全うできません。使用条件によっては、極めて短時間に寿命に至ることがあります。

- 1. 給油と給脂の最大の目的は、チェーンの摩耗伸びをおさえ腐食を防止することです。

摩耗伸びは、屈曲部に起こるピンとブシュ間の摩耗によって生じます。 - 2. ローラチェーンの一部に採用されている防錆潤滑油は、防錆と潤滑の効果がある高級油を使用しています。

運転初期に起こりやすい摩耗を防ぎ、また潤滑油と親和して耐摩耗性を確保します。 - 3. 納入されたローラチェーンの塗油を、布で拭き取ったり、洗浄剤などで洗い落とすことは避けてください。

3.1 給油の位置

- 1. ローラチェーンの摩耗伸びは、ピンとブシュ間の摩耗によって生じます。給油は、この部分に行います。

- 2. ローラチェーンのたるみ側で、外プレートと内プレートの隙間へ潤滑油が入るようにします。同時にブシュとローラ間にも給油します。

図12. 給油の位置

3.2 吊下げの場合

- 1. 一般にたるみ側がありませんが、できるだけローラチェーンに作用する荷重を除去した状態で給油します。

- 2. 屈曲しない箇所のローラチェーンには、給油した上で、腐食防止のためにグリースをローラチェーンのまわりに厚く塗布します。端末金具との連結部にも給油します。

- 3. 屋外で使用するローラチェーンに雨や雪がかかると、油脂分が流れ、腐食します。カバーなどの保護具を取付けてください。

雨や雪がかかったときは、水分を除去した後で、速やかにローラチェーンに給油し、その上へグリースを厚く塗布します。

3.3 潤滑油の種類について

推奨SAE番号

| チェーン番号 | 潤滑形式 | |||||||

|---|---|---|---|---|---|---|---|---|

| AI・AII・B | C | |||||||

| 周囲温度 | 周囲温度 | |||||||

| -10℃~0℃ | 0℃~40℃ | 40℃~50℃ | 50℃~60℃ | -10℃~0℃ | 0℃~40℃ | 40℃~50℃ | 50℃~60℃ | |

| RS50以下の小ピッチのもの | SAE10W | SAE20 | SAE30 | SAE40 | SAE10W | SAE20 | SAE30 | SAE40 |

| RS60・80 | SAE20 | SAE30 | SAE40 | SAE50 | ||||

| RS100 | SAE20 | SAE30 | SAE40 | SAE50 | ||||

| RS120以上の大ピッチのもの | SAE30 | SAE40 | SAE50 | |||||

3.4 潤滑形式と給油方法

運転を停止してから、給油を行います。

給油状況を調べるには、チェーンを取外して、継手部のピンおよびブシュの表面状態を観察します。

ピンやブシュの表面にむしれや摩耗、および赤色や暗褐色の表面が観察された場合は、一般に給油が不足しています。

| 潤滑形式 | 方法 | 給油量 | |||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

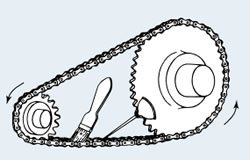

| A | I |

ローラチェーンのたるみ側のピン、および内リンクの間隙を狙って油差し、またはブラシで給油する方法です。 |

定期的(一般には8時間毎位)にローラチェーンの軸受部が乾燥しない程度で |

||||||||||||||||||||||||||||||||||

| II |

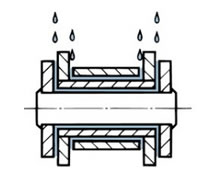

滴下給油

簡単なケースを用い、オイルカップなどの油槽から送られる油を滴下する方法です。 |

ローラチェーン1列は、1分間に5~20滴程度の油量を給油してください。 また、速度が早いほど滴下量を増やします。 |

|||||||||||||||||||||||||||||||||||

| B |

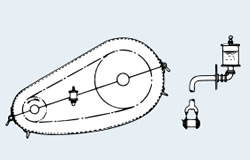

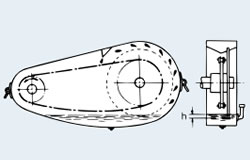

油浴給油

油洩れを起こさないケースを用い、油の中を走らせる方法です。 |

油面からローラチェーン最下点までの深さhが過大の場合は、油が80℃以上に発熱して変質する恐れがあります。 ローラチェーンが油につかる深さをh=6~12mm位に設定します。 |

|||||||||||||||||||||||||||||||||||

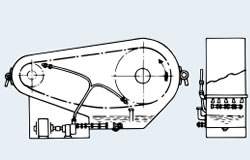

|

回転板による給油

油洩れを起こさないケースの中に取付けた回転板を使って、チェーンに油をかける方法です。 回転板の周速は200m/min以上にしてください。 チェーンの幅が125mm以上のときは、回転板を両側に付けてください。 |

回転板の最下部は、油面よりh=12~25mm位まで下げてください。 ローラチェーンは油に浸からないようにします。 |

||||||||||||||||||||||||||||||||||||

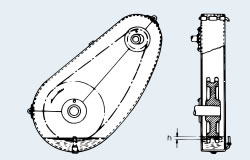

| C |

強制ポンプ潤滑

油洩れを起こさないケースを用い、ポンプによって油を循環冷却させながら強制的に給油を行う方法です。 チェーンがn列のとき、給油穴は各部すきまを狙ってn+1個必要です。 |

給油穴1個当りの概略給油量(L/min)

|

|||||||||||||||||||||||||||||||||||