技術資料 ケーブルベヤ - ケーブルベヤの取扱 - ケーブル・ホースの配線、保守

ケーブル・ホースの配線

■柔軟性に富み、繰返し屈曲性・耐久性に優れた移動用のケーブル・ホースを使用してください。

ワイヤーブレード被覆のものは使用禁止です。摺動によりケーブルベヤとワイヤーブレードの双方がいたみますので、使用しないでください。

■ケーブル・ホースはねじれのないように、配線してください。ドラムやコイルからスパイラル状に引き出すと、ケーブル・ホースがねじれた状態で配線されますので、行わないでください。(図1参照)

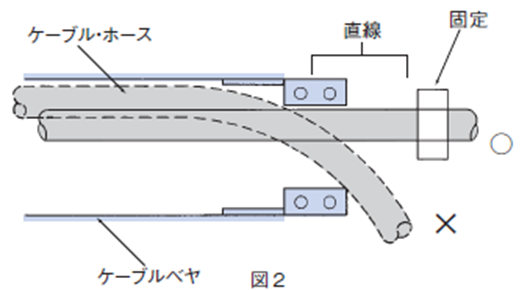

ケーブル・ホースは、直線状態でケーブルベヤ内にはいるようにしてください。(図2参照)

■ケーブル・ホースの必要長さ

ケーブルの長さは通常

とするのが適当です。

ホースの場合は使用時に圧力により長さが変化するので

とするのが適当です。

なお、係数1.015はホースの収縮を見込んだ値ですが、ホースの種類によって異なりますので、ホースメーカーにご確認ください。

■ケーブル・ホースは屈曲部で引張り勝手やケーブルベヤ外周面に押付けた状態にならないよう、緩ませ気味(ケーブルベヤ内周面より浮き上がり)に、自由に動けるように配線してください。(図3・図4参照)

■ケーブル・ホースに不要な張力が作用しないように、ケーブルベヤ内での長さを保つために移動端および固定端部で固定(クランプ)してください。(図5参照)

なお、ケーブル・ホースをケーブルベヤ内では固定しないでください。

■ケーブル・ホースは、横一列に配列し、積み重ねないでください。仕切板を取付けられるタイプでは、仕切板によりケーブル・ホースを整頓してください。

■ケーブル・ホースを多段に仕切る場合、ケーブル・ホースの長さは、内外周では同一ではありません。それぞれのケーブル・ホースの中心ライン上で必要長さを求めてください。

ただし、ケーブル・ホースを多段に仕切ると、ケーブル・ホースが摺動により、摩耗しやすくなりますので、横一列に並べることをおすすめします。

保守

■運搬時や走行時の振動などにより、リンクやサポータ部のボルトが緩んでくる場合もありますので、運転後定期的に点検してください。(TK形・TKS形・TKH形)

■ガイドレール上に異物が落ちたり、堆積しないように注意してください。

■ケーブルベヤがスムーズに往復移動しているか、ケーブル・ホースが無理に引張られていないか、またケーブルは繰返し屈曲すると内部のよりが戻って、長さが変化することがありますので、定期的に点検してください。