技術資料 タイミングベルト・タイミングプーリ 取扱

取扱説明(ロックプーリ® Nタイプ)

取扱説明

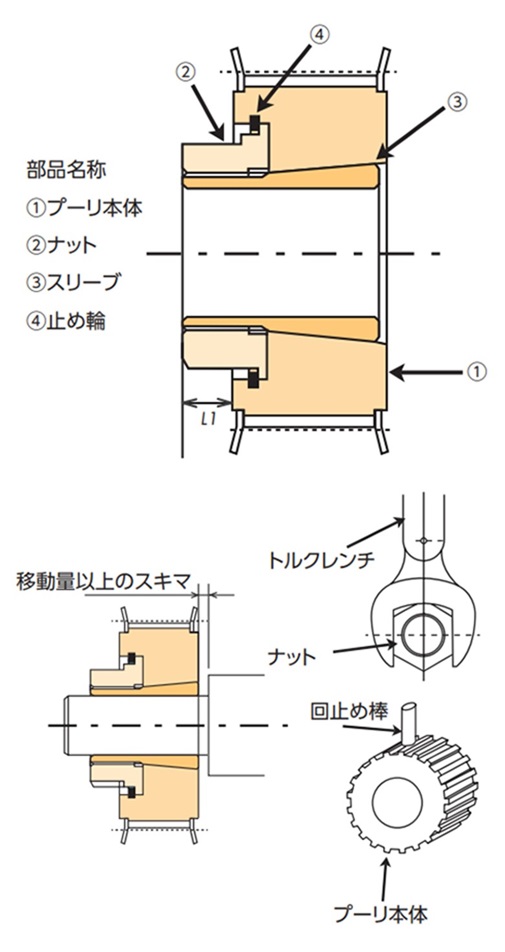

取付け

- 1) 軸表面のゴミをふき取り、オイルまたはグリースを薄く塗ってください。(モリブデン系の減摩剤を含有したオイル、グリースは使用しないでください。)

- 2) スリーブ・ナットおよび止め輪はプーリ本体に組立ててありますので、そのまま軸に取付けてください。取付けにくい時はナットを緩み方向に回してください。取付けが容易になります。

1ヶ月以上保管後使用される時は、スリーブを取外した後、スリーブ外周に付着したゴミをふき取りオイルまたはグリースを塗ってください。 (モリブデン系の減摩剤を含有したオイル、グリースは使用しないでください。) - 3) プーリ本体の回転止めを行いナットを手締めすることでロックプーリを軸の所定位置にまたは所定位相位置に仮固定することが出来ます。

- 4) トルクレンチを使用し規定締付トルクMA(下表)でナットを締付けてください。

- 5) ナット締付けに対して軸またはプーリ本体の回転止めを確実にして締付けてください。プーリ本体の回転止めの一方法としてプーリ外周部に穴を開け、穴に回止め棒を使用する方法があります。(穴開け加工後はバリ・カエリを十分除去ください。)

- 6) 締付けに際してプーリ本体はナットと反対方向に0.2~2.0mm程度移動しますのでプーリアライメントおよび軸の段に注意してください。

ナット締付トルク MA

| スリーブ枠番 | ナットの二面幅寸法 mm |

ナット締付トルク MA N・m {kgf・m} |

|---|---|---|

| N1 | 18 | 18 {1.84} |

| N2 | 22 | 28 {2.86} |

| N3 | 30 | 65 {6.63} |

| N4 | 36 | 100 {10.20} |

| N5 | 41 | 130 {13.27} |

| N6 | 46 | 200 {20.41} |

取外し

- 1) プーリと軸にトルク、スラスト荷重がかかっていないことを確認した後、ナットを緩めてください。

- 2) ナットを緩めるに際して、軸またはプーリ本体の周止めを確実に行ってください。

- 3) ナットを緩めることにより軸とプーリの締結が解除されます。

一般注意事項

- 1) ナットの締付けに際しては、必ずトルクレンチを使用してください。手締め、パイプを継ぎたした締付け等不正確な締付けは正確な伝達トルクを得られぬばかりかトラブルの原因となりますのでお止めください。

- 2) 使用温度範囲:-15℃~80℃(アルミ:0℃~50℃)

- 3) トルクレンチはご使用になるトルクレンチの取扱説明書に従い正しくご使用ください。

- 4) 軸穴公差および表面粗さ:軸径の公差h8、軸表面粗さはRa3.2としてください。