技術資料 タイミングベルト・タイミングプーリ 設計資料

選定・設計(ロックプーリ Sタイプ・Sタイプ メッキ仕様)

最大伝達トルクの確認

ロックプーリSタイプの選定は次の手順で行ってください。

発生する伝達容量に対して使用係数を乗じて最大発生トルク、最大発生スラスト荷重を求めます。

最大発生トルク Tmax

[SI単位系]

Tmax (N・m) = 9550 × KW × SF n

[重力単位]

Tmax (kgf・m) = 974 × KW × SF n

最大発生スラスト荷重 Pmax

Pmax (N{kgf}) = Pax × SF

- KW:伝達容量 kW

- SF:使用係数 (下表より選択)

- n:回転速度 r/min

- Pax:最大スラスト荷重 N{kgf}

トルクとスラスト荷重が同時にかかるときは次式にて合成負荷MRmaxを算出します。

MRmax = (Tmax)2 + (Pmax × d/2000)2 N・m{kgf・m} d:軸径(mm)

上で求めたTmaxまたはMRmaxをスリーブの伝達トルクMtと比較します。

Mt ≧ TmaxまたはMRmaxなら使用可能です。

Mt < TmaxまたはMRmaxなら使用不可です。

使用係数 SF

| 負荷の状態 | 使用係数 SF | |

|---|---|---|

| 衝撃のない平滑な伝動 | 負荷慣性小 慣性比1.0以下 |

1.2~1.5 |

| 軽い衝撃のある伝動 | 負荷慣性中 慣性比1.0~3.0 |

1.5~2.0 |

| 大きな衝撃の負荷 あるいは正逆転 |

負荷慣性大 慣性比3.0以上 |

2.0~5.0 |

軸の検討

軸は次式を満足する材質のものをご使用ください。

δ0.2S ≧ 1.2 × P

δ0.2S:使用軸材料の降伏点(MPa) P:軸側面圧(Mpa)

中空軸を使用する場合は、次式を満足する内径寸法dBの軸を使用ください。

dB ≦ d × δ0.2S - 2 × P δ0.2S

d:軸径(mm) δ0.2S:使用軸材料の降伏点(MPa)

アルミタイプについて

低温(0°以下)、高温(50°以上)で使用の際は、熱膨張による寸法変化で、ベルトとプーリのかみ合いズレが発生し、ベルトの早期摩耗などの原因となる場合がありますので当社までご相談ください。

| [参考] 熱膨張係数 | 比重(g/cm3) |

| アルミ:23.9 × 10-6 | 2.8 |

| 炭素鋼:11.7 × 10-6 | 7.8 |

概算質量

標準取付けの場合は、標準プーリの質量に表中加算質量を加えた質量が概算質量になります。

フラット取付けの場合は、標準プーリの質量から表中減算質量を減じた質量が概算質量になります。

| スリーブ枠番 | 取付方法 | |

|---|---|---|

| 標準取付 | フラット取付 | |

| 加算質量 kg | 減算質量 kg | |

| S1 | 0.1 | 0.1 |

| S2 | 0.1 | 0.1 |

| S3 | 0.1 | 0.2 |

| S4 | 0.2 | 0.3 |

| S5 | 0.3 | 0.4 |

| S6 | 0.5 | 0.6 |

| S7 | 0.9 | 1.0 |

スリーブ諸元(ロックプーリSタイプ)

※クリックで開閉します。

スリーブ諸元(ロックプーリSタイプ)

※クリックで開閉します。

Sタイプ スリーブ仕様

| スリーブ | 材質 | 機械構造用炭素鋼 |

|---|---|---|

| 熱処理 | 焼入焼戻 | |

| 締付ボルト | 六角穴付ボルト(JIS B 1176) 強度区分:12.9 |

|

| 材質 | 構造用合金鋼 | |

| 熱処理 | 焼入焼戻 | |

| 表面処理 | 黒色酸化皮膜処理 | |

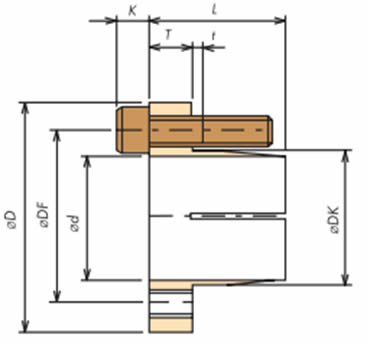

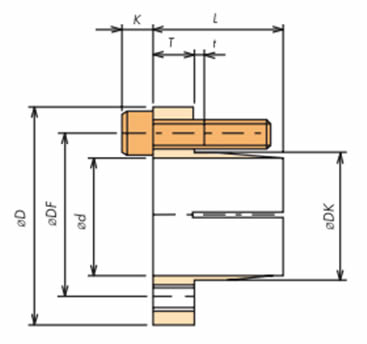

スリーブ寸法

| スリーブ 枠番 |

軸穴径 d |

スリーブ 外径 ΦD |

取付穴 ピッチ円 直径 ΦDF |

テーパ 外径 ΦDK |

スリーブ 全長 L |

フランジ 厚さ T |

ストレート部 長さ t |

ボルト頭 高さ k |

締付 ボルト サイズ |

ねじ穴 | 締付トルク N・m {kgf・m} |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 10 | 32 | 24 | 18.6 | 18 | 6 | 2 | 4 | M4×16 | M4 | 4.2 {0.43} |

| 11 | |||||||||||

| 12 | |||||||||||

| 14 | |||||||||||

| 15 | |||||||||||

| 16 | |||||||||||

| S2 | 15 | 42 | 32 | 25.2 | 22 | 7 | 2 | 5 | M5×18 | M5 | 8.3 {0.85} |

| 16 | |||||||||||

| 17 | |||||||||||

| 18 | |||||||||||

| 19 | |||||||||||

| 20 | |||||||||||

| 22 | |||||||||||

| S3 | 24 | 48.5 | 38.5 | 31.2 | 23.5 | 8 | 2.5 | 5 | M5×20 | M5 | 8.3 {0.85} |

| 25 | |||||||||||

| 28 | |||||||||||

| S4 | 24 | 56 | 46 | 38.6 | 26 | 8 | 2.5 | 5 | M5×20 | M5 | 8.3 {0.85} |

| 25 | |||||||||||

| 28 | |||||||||||

| 30 | |||||||||||

| 32 | |||||||||||

| 35 | |||||||||||

| S5 | 35 | 66 | 56 | 48.8 | 29 | 10 | 2.5 | 5 | M5×22 | M5 | 8.3 {0.85} |

| 38 | |||||||||||

| 40 | |||||||||||

| 42 | |||||||||||

| 45 | |||||||||||

| S6 | 48 | 80 | 68 | 60 | 36 | 12 | 3 | 6 | M6×25 | M6 | 16.8 {1.71} |

| 50 | |||||||||||

| 55 | |||||||||||

| S7 | 60 | 101 | 86 | 75.5 | 40 | 13 | 3.5 | 8 | M8×30 | M8 | 40.5 {4.13} |

| 65 | |||||||||||

| 70 |

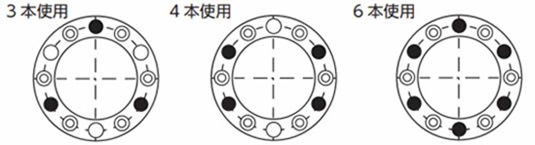

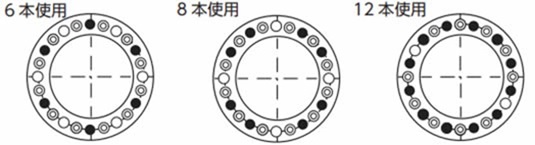

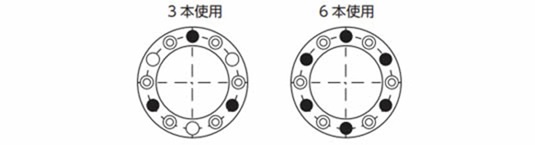

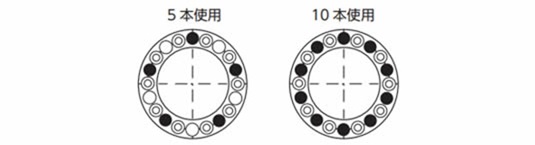

締付ボルト使用位置

・締付ボルトの使用位置 ○空き穴 ◎ねじ穴(スリーブ取外し用ねじ穴)

| スリーブ 枠番 |

締付ボルトの使用位置 | スリーブ 枠番 |

締付ボルトの使用位置 |

|---|---|---|---|

| S1 |  |

S5 |  |

| S2 |  |

S6 |  |

| S3 |  |

S7 |  |

| S4 |  |

スリーブ諸元(ロックプーリSタイプ)

※クリックで開閉します。

スリーブ諸元(ロックプーリSタイプ)

※クリックで開閉します。

スリーブ性能

| スリーブ 枠番 |

ボルト 本数 |

軸穴径 d mm |

ボルト サイズ |

ボルト締付トルク MA N・m {kgf・m} |

伝達トルク Mt N・m {kgf・m} |

スラスト荷重 Pax kN {kgf} |

軸側面圧 P MPa {kgf/mm2} |

ハブ側面圧 P' MPa {kgf/mm2} |

最小ハブ直径 mm | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 材質 | ||||||||||||

| SS400 | S35C | S45C | A7075-T6 | |||||||||

| S1 | 3 | 10 | M4×16 | 4.2 {0.43} | 43 {4.4} | 8.6 {882} | 196 {20.0} | 111 {11.3} | 35 | 30 | 29 | 29 |

| 11 | 48 {4.8} | 8.6 {882} | 179 {18.2} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 12 | 52 {5.3} | 8.6 {882} | 164 {16.7} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 14 | 60 {6.2} | 8.6 {882} | 140 {14.3} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 15 | 65 {6.6} | 8.6 {882} | 131 {13.4} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 16 | 69 {7.1} | 8.6 {882} | 123 {12.5} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 4 | 10 | 58 {5.9} | 11.5 {1176} | 262 {26.7} | 148 {15.1} | 44 | 34 | 32 | 33 | |||

| 11 | 63 {6.5} | 11.5 {1176} | 238 {24.3} | 148 {15.1} | 44 | 34 | 32 | 33 | ||||

| 12 | 69 {7.1} | 11.5 {1176} | 218 {22.3} | 148 {15.1} | 44 | 34 | 32 | 33 | ||||

| 14 | 81 {8.2} | 11.5 {1176} | 187 {19.1} | 148 {15.1} | 44 | 34 | 32 | 33 | ||||

| 15 | 86 {8.8} | 11.5 {1176} | 175 {17.8} | 148 {15.1} | 44 | 34 | 32 | 33 | ||||

| 16 | 92 {9.4} | 11.5 {1176} | 164 {16.7} | 148 {15.1} | 44 | 34 | 32 | 33 | ||||

| 6 | 14 | 121 {12.3} | 17.3 {1764} | 281 {28.6} | 222 {22.6} | 使用不可 | 49 | 42 | 44 | |||

| 15 | 130 {13.2} | 17.3 {1764} | 262 {26.7} | 222 {22.6} | 使用不可 | 49 | 42 | 44 | ||||

| 16 | 138 {14.1} | 17.3 {1764} | 245 {25.0} | 222 {22.6} | 使用不可 | 49 | 42 | 44 | ||||

| S2 | 3 | 15 | M5×18 | 8.3 {0.85} | 105 {10.7} | 13.9 {1423} | 163 {16.6} | 101 {10.3} | 45 | 39 | 38 | 38 |

| 16 | 112 {11.4} | 13.9 {1423} | 152 {15.5} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 17 | 119 {12.1} | 13.9 {1423} | 143 {14.6} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 18 | 126 {12.8} | 13.9 {1423} | 135 {13.8} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 19 | 133 {13.5} | 13.9 {1423} | 128 {13.1} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 20 | 139 {14.2} | 13.9 {1423} | 122 {12.4} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 22 | 153 {15.7} | 13.9 {1423} | 111 {11.3} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 4 | 15 | 139 {14.2} | 18.6 {1898} | 217 {22.1} | 135 {13.8} | 54 | 44 | 41 | 42 | |||

| 16 | 149 {15.2} | 18.6 {1898} | 203 {20.7} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 17 | 158 {16.1} | 18.6 {1898} | 191 {19.5} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 18 | 167 {17.1} | 18.6 {1898} | 181 {18.4} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 19 | 177 {18.0} | 18.6 {1898} | 171 {17.5} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 20 | 186 {19.0} | 18.6 {1898} | 163 {16.6} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 22 | 205 {20.9} | 18.6 {1898} | 148 {15.1} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 6 | 17 | 237 {24.2} | 27.9 {2846} | 287 {29.3} | 203 {20.7} | 124 | 59 | 52 | 54 | |||

| 18 | 251 {25.6} | 27.9 {2846} | 271 {27.6} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 19 | 265 {27.0} | 27.9 {2846} | 257 {26.2} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 20 | 279 {28.5} | 27.9 {2846} | 244 {24.9} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 22 | 307 {31.3} | 27.9 {2846} | 222 {22.6} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| S3 | 3 | 24 | M5×20 | 8.3 {0.85} | 167 {17.1} | 13.9 {1423} | 102 {10.4} | 81 {8.3} | 49 | 44 | 43 | 44 |

| 25 | 174 {17.8} | 13.9 {1423} | 98 {10.0} | 81 {8.3} | 49 | 44 | 43 | 44 | ||||

| 28 | 195 {19.9} | 13.9 {1423} | 87 {8.9} | 81 {8.3} | 49 | 44 | 43 | 44 | ||||

| 4 | 24 | 223 {22.8} | 18.6 {1898} | 135 {13.8} | 108 {11.0} | 56 | 49 | 47 | 47 | |||

| 25 | 232 {23.7} | 18.6 {1898} | 130 {13.3} | 108 {11.0} | 56 | 49 | 47 | 47 | ||||

| 28 | 260 {26.6} | 18.6 {1898} | 116 {11.8} | 108 {11.0} | 56 | 49 | 47 | 47 | ||||

| 6 | 24 | 335 {34.2} | 27.9 {2846} | 203 {20.7} | 162 {16.6} | 82 | 59 | 55 | 57 | |||

| 25 | 349 {35.6} | 27.9 {2846} | 195 {19.9} | 162 {16.6} | 82 | 59 | 55 | 57 | ||||

| 28 | 391 {39.9} | 27.9 {2846} | 174 {17.8} | 162 {16.6} | 82 | 59 | 55 | 57 | ||||

| S4 | 3 | 24 | M5×20 | 8.3 {0.85} | 167 {17.1} | 13.9 {1423} | 85 {8.7} | 55 {5.6} | 53 | 50 | 49 | 49 |

| 25 | 174 {17.8} | 13.9 {1423} | 82 {8.3} | 55 {5.6} | 53 | 50 | 49 | 49 | ||||

| 28 | 195 {19.9} | 13.9 {1423} | 73 {7.5} | 55 {5.6} | 53 | 50 | 49 | 49 | ||||

| 30 | 209 {21.3} | 13.9 {1423} | 68 {7.0} | 55 {5.6} | 53 | 50 | 49 | 49 | ||||

| 32 | 223 {22.8} | 13.9 {1423} | 64 {6.5} | 55 {5.6} | 53 | 50 | 49 | 49 | ||||

| 35 | 244 {24.9} | 13.9 {1423} | 58 {6.0} | 55 {5.6} | 53 | 50 | 49 | 49 | ||||

| 4 | 24 | 223 {22.8} | 18.6 {1898} | 114 {11.6} | 73 {7.5} | 58 | 53 | 51 | 52 | |||

| 25 | 232 {23.7} | 18.6 {1898} | 109 {11.1} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 28 | 260 {26.6} | 18.6 {1898} | 97 {9.9} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 30 | 279 {28.5} | 18.6 {1898} | 91 {9.3} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 32 | 298 {30.4} | 18.6 {1898} | 85 {8.7} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 35 | 325 {33.2} | 18.6 {1898} | 78 {7.9} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 6 | 24 | 335 {34.2} | 27.9 {2846} | 170 {17.4} | 110 {11.2} | 69 | 59 | 57 | 58 | |||

| 25 | 349 {35.6} | 27.9 {2846} | 164 {16.7} | 110 {11.2} | 69 | 59 | 57 | 58 | ||||

| 28 | 391 {39.9} | 27.9 {2846} | 146 {14.9} | 110 {11.2} | 69 | 59 | 57 | 58 | ||||

| 30 | 418 {42.7} | 27.9 {2846} | 136 {13.9} | 110 {11.2} | 69 | 59 | 57 | 58 | ||||

| 32 | 446 {45.5} | 27.9 {2846} | 128 {13.0} | 110 {11.2} | 69 | 59 | 57 | 58 | ||||

| 35 | 488 {49.8} | 27.9 {2846} | 117 {11.9} | 110 {11.2} | 69 | 59 | 57 | 58 | ||||

| 8 | 24 | 446 {45.5} | 37.2 {3795} | 227 {23.2} | 146 {14.9} | 88 | 68 | 64 | 65 | |||

| 25 | 465 {47.4} | 37.2 {3795} | 218 {22.3} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| 28 | 521 {53.1} | 37.2 {3795} | 195 {19.9} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| 30 | 558 {56.9} | 37.2 {3795} | 182 {18.5} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| 32 | 595 {60.7} | 37.2 {3795} | 170 {17.4} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| 35 | 651 {66.4} | 37.2 {3795} | 156 {15.9} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| S5 | 5 | 35 | M5×22 | 8.3 {0.85} | 407 {41.5} | 23.2 {2372} | 91 {9.3} | 68 {6.9} | 70 | 64 | 63 | 63 |

| 38 | 442 {45.1} | 23.2 {2372} | 84 {8.6} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 40 | 465 {47.4} | 23.2 {2372} | 80 {8.2} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 42 | 488 {49.8} | 23.2 {2372} | 76 {7.8} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 45 | 523 {53.4} | 23.2 {2372} | 71 {7.3} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 8 | 35 | 651 {66.4} | 37.2 {3795} | 146 {14.9} | 108 {11.0} | 86 | 74 | 71 | 72 | |||

| 38 | 707 {72.1} | 37.2 {3795} | 135 {13.8} | 108 {11.0} | 86 | 74 | 71 | 72 | ||||

| 40 | 744 {75.9} | 37.2 {3795} | 128 {13.1} | 108 {11.0} | 86 | 74 | 71 | 72 | ||||

| 42 | 781 {79.7} | 37.2 {3795} | 122 {12.4} | 108 {11.0} | 86 | 74 | 71 | 72 | ||||

| 45 | 837 {85.4} | 37.2 {3795} | 114 {11.6} | 108 {11.0} | 86 | 74 | 71 | 72 | ||||

| 10 | 35 | 814 {83.0} | 46.5 {4744} | 183 {18.7} | 135 {13.8} | 102 | 81 | 77 | 78 | |||

| 38 | 883 {90.1} | 46.5 {4744} | 169 {17.2} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| 40 | 930 {94.9} | 46.5 {4744} | 160 {16.3} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| 42 | 976 {99.6} | 46.5 {4744} | 152 {15.6} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| 45 | 1046 {106.7} | 46.5 {4744} | 142 {14.5} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| S6 | 6 | 48 | M6×25 | 16.8 {1.71} | 1116 {113.9} | 46.5 {4744} | 105 {10.7} | 87 {8.8} | 94 | 84 | 81 | 82 |

| 50 | 1162 {118.6} | 46.5 {4744} | 101 {10.3} | 87 {8.8} | 94 | 84 | 81 | 82 | ||||

| 55 | 1279 {130.5} | 46.5 {4744} | 91 {9.3} | 87 {8.8} | 94 | 84 | 81 | 82 | ||||

| 8 | 48 | 1488 {151.8} | 62.0 {6326} | 140 {14.3} | 115 {11.8} | 110 | 93 | 88 | 90 | |||

| 50 | 1550 {158.1} | 62.0 {6326} | 134 {13.7} | 115 {11.8} | 110 | 93 | 88 | 90 | ||||

| 55 | 1705 {174.0} | 62.0 {6326} | 122 {12.4} | 115 {11.8} | 110 | 93 | 88 | 90 | ||||

| 10 | 48 | 1860 {189.8} | 77.5 {7907} | 175 {17.8} | 144 {14.7} | 134 | 103 | 97 | 99 | |||

| 50 | 1937 {197.7} | 77.5 {7907} | 168 {17.1} | 144 {14.7} | 134 | 103 | 97 | 99 | ||||

| 55 | 2131 {217.4} | 77.5 {7907} | 152 {15.6} | 144 {14.7} | 134 | 103 | 97 | 99 | ||||

| 12 | 48 | 2232 {227.7} | 93.0 {9488} | 210 {21.4} | 173 {17.7} | 174 | 117 | 107 | 110 | |||

| 50 | 2325 {237.2} | 93.0 {9488} | 201 {20.5} | 173 {17.7} | 174 | 117 | 107 | 110 | ||||

| 55 | 2557 {260.9} | 93.0 {9488} | 183 {18.7} | 173 {17.7} | 174 | 117 | 107 | 110 | ||||

| S7 | 5 | 60 | M8×30 | 40.5 {4.13} | 2140 {218.4} | 71.3 {7280} | 115 {11.7} | 94 {9.6} | 124 | 109 | 105 | 107 |

| 65 | 2319 {236.6} | 71.3 {7280} | 106 {10.8} | 94 {9.6} | 124 | 109 | 105 | 107 | ||||

| 70 | 2497 {254.8} | 71.3 {7280} | 99 {10.1} | 94 {9.6} | 124 | 109 | 105 | 107 | ||||

| 8 | 60 | 3424 {349.4} | 114.1 {11648} | 184 {18.8} | 150 {15.3} | 177 | 134 | 125 | 128 | |||

| 65 | 3710 {378.6} | 114.1 {11648} | 170 {17.3} | 150 {15.3} | 177 | 134 | 125 | 128 | ||||

| 70 | 3995 {407.7} | 114.1 {11648} | 158 {16.1} | 150 {15.3} | 177 | 134 | 125 | 128 | ||||

| 10 | 60 | 4281 {436.8} | 142.7 {14560} | 230 {23.5} | 188 {19.2} | 270 | 159 | 143 | 149 | |||

| 65 | 4637 {473.2} | 142.7 {14560} | 212 {21.7} | 188 {19.2} | 270 | 159 | 143 | 149 | ||||

| 70 | 4994 {509.6} | 142.7 {14560} | 197 {20.1} | 188 {19.2} | 270 | 159 | 143 | 149 | ||||

スリーブ諸元(ロックプーリSタイプ メッキ仕様)

※クリックで開閉します。

スリーブ諸元(ロックプーリSタイプ メッキ仕様)

※クリックで開閉します。

Sタイプ メッキ仕様 スリーブ仕様

| スリーブ | 材質 | 機械構造用炭素鋼 |

|---|---|---|

| 熱処理 | 焼入焼戻 | |

| 表面処理 | 無電解ニッケルりんめっき | |

| 締付ボルト | 六角穴付ボルト(JIS B 1176) 強度区分:12.9 |

|

| 材質 | 構造用合金鋼 | |

| 熱処理 | 焼入焼戻 | |

| 表面処理 | 特殊コーティング | |

スリーブ寸法

| スリーブ 枠番 |

軸穴径 d |

スリーブ 外径 ΦD |

取付穴 ピッチ円 直径 ΦDF |

テーパ 外径 ΦDK |

スリーブ 全長 L |

フランジ 厚さ T |

ストレート部 長さ t |

ボルト頭 高さ k |

締付 ボルト サイズ |

|---|---|---|---|---|---|---|---|---|---|

| S1 | 10 | 32 | 24 | 18.6 | 18 | 6 | 2 | 4 | M4×16 |

| 11 | |||||||||

| 12 | |||||||||

| 14 | |||||||||

| 15 | |||||||||

| 16 | |||||||||

| S2 | 17 | 42 | 32 | 25.2 | 22 | 7 | 2 | 5 | M5×20 |

| 18 | |||||||||

| 19 | |||||||||

| 20 | |||||||||

| 22 | |||||||||

| S3 | 24 | 48.5 | 38.5 | 31.2 | 23.5 | 8 | 2.5 | 5 | M5×20 |

| 25 | |||||||||

| 28 | |||||||||

| S4 | 30 | 56 | 46 | 38.6 | 26 | 8 | 2.5 | 5 | M5×20 |

| 32 | |||||||||

| 35 | |||||||||

| S5 | 38 | 66 | 56 | 48.8 | 29 | 10 | 2.5 | 5 | M5×25 |

| 40 | |||||||||

| 42 | |||||||||

| 45 | |||||||||

| S6 | 48 | 80 | 68 | 60 | 36 | 12 | 3 | 6 | M6×25 |

| 50 | |||||||||

| 55 | |||||||||

| S7 | 60 | 101 | 86 | 75.5 | 40 | 13 | 3.5 | 8 | M8×30 |

| 65 | |||||||||

| 70 |

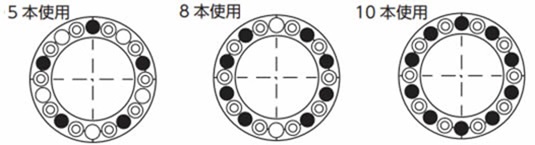

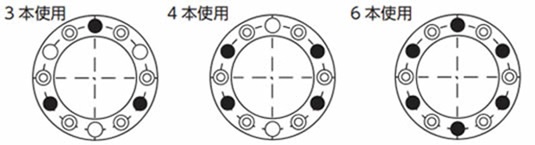

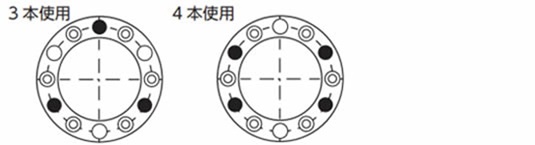

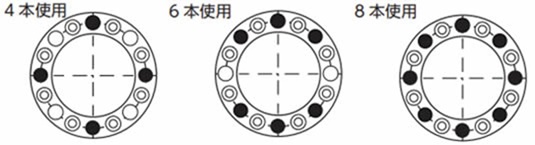

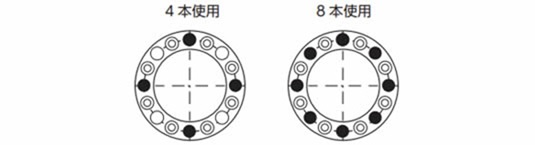

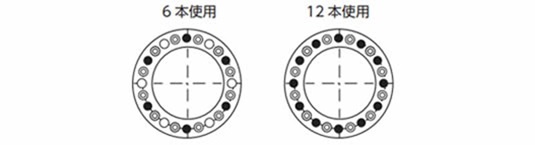

締付ボルト使用位置

・締付ボルトの使用位置 ○空き穴 ◎ねじ穴(スリーブ取外し用ねじ穴)

| スリーブ 枠番 |

締付ボルトの使用位置 | スリーブ 枠番 |

締付ボルトの使用位置 |

|---|---|---|---|

| S1 S2 S3 |

|

S5 S7 |

|

| S4 |  |

S6 |  |

スリーブ諸元(ロックプーリSタイプ メッキ仕様)

※クリックで開閉します。

スリーブ諸元(ロックプーリSタイプ メッキ仕様)

※クリックで開閉します。

スリーブ性能

| スリーブ 枠番 |

ボルト 本数 |

軸穴径 d mm |

ボルト サイズ |

ボルト締付トルク MA N・m {kgf・m} |

伝達トルク Mt N・m {kgf・m} |

スラスト荷重 Pax kN {kgf} |

軸側面圧 P MPa {kgf/mm2} |

ハブ側面圧 P' MPa {kgf/mm2} |

最小ハブ直径 mm | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 材質 | ||||||||||||

| SS400 | S35C | S45C | A7075-T6 | |||||||||

| S1 | 3 | 10 | M4×16 | 3.4 {0.35} | 43 {4.4} | 8.6 {882} | 196 {20.0} | 111 {11.3} | 35 | 30 | 29 | 29 |

| 11 | 48 {4.8} | 8.6 {882} | 179 {18.2} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 12 | 52 {5.3} | 8.6 {882} | 164 {16.7} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 14 | 60 {6.2} | 8.6 {882} | 140 {14.3} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 15 | 65 {6.6} | 8.6 {882} | 131 {13.4} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 16 | 69 {7.1} | 8.6 {882} | 123 {12.5} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 6 | 14 | 121 {12.3} | 17.3 {1764} | 281 {28.6} | 222 {22.6} | 使用不可 | 49 | 42 | 44 | |||

| 15 | 130 {13.2} | 17.3 {1764} | 262 {26.7} | 222 {22.6} | 使用不可 | 49 | 42 | 44 | ||||

| 16 | 138 {14.1} | 17.3 {1764} | 245 {25.0} | 222 {22.6} | 使用不可 | 49 | 42 | 44 | ||||

| S2 | 3 | 17 | M5×20 | 6.8 {0.69} | 119 {12.1} | 13.9 {1423} | 143 {14.6} | 101 {10.3} | 45 | 39 | 38 | 38 |

| 18 | 126 {12.8} | 13.9 {1423} | 135 {13.8} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 19 | 133 {13.5} | 13.9 {1423} | 128 {13.1} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 20 | 139 {14.2} | 13.9 {1423} | 122 {12.4} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 22 | 153 {15.7} | 13.9 {1423} | 111 {11.3} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 6 | 17 | 237 {24.2} | 27.9 {2846} | 287 {29.3} | 203 {20.7} | 124 | 59 | 52 | 54 | |||

| 18 | 251 {25.6} | 27.9 {2846} | 271 {27.6} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 19 | 265 {27.0} | 27.9 {2846} | 257 {26.2} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 20 | 279 {28.5} | 27.9 {2846} | 244 {24.9} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 22 | 307 {31.3} | 27.9 {2846} | 222 {22.6} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| S3 | 3 | 24 | M5×20 | 6.8 {0.69} | 167 {17.1} | 13.9 {1423} | 102 {10.4} | 81 {8.3} | 49 | 44 | 43 | 44 |

| 25 | 174 {17.8} | 13.9 {1423} | 98 {10.0} | 81 {8.3} | 49 | 44 | 43 | 44 | ||||

| 28 | 195 {19.9} | 13.9 {1423} | 87 {8.9} | 81 {8.3} | 49 | 44 | 43 | 44 | ||||

| 6 | 24 | 335 {34.2} | 27.9 {2846} | 203 {20.7} | 162 {16.6} | 82 | 59 | 55 | 57 | |||

| 25 | 349 {35.6} | 27.9 {2846} | 195 {19.9} | 162 {16.6} | 82 | 59 | 55 | 57 | ||||

| 28 | 391 {39.9} | 27.9 {2846} | 174 {17.8} | 162 {16.6} | 82 | 59 | 55 | 57 | ||||

| S4 | 4 | 30 | M5×20 | 6.8 {0.69} | 279 {28.5} | 18.6 {1898} | 91 {9.3} | 73 {7.5} | 58 | 53 | 51 | 52 |

| 32 | 298 {30.4} | 18.6 {1898} | 85 {8.7} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 35 | 325 {33.2} | 18.6 {1898} | 78 {7.9} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 8 | 30 | 558 {56.9} | 37.2 {3795} | 182 {18.5} | 146 {14.9} | 88 | 68 | 64 | 65 | |||

| 32 | 595 {60.7} | 37.2 {3795} | 170 {17.4} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| 35 | 651 {66.4} | 37.2 {3795} | 156 {15.9} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| S5 | 5 | 38 | M5×25 | 6.8 {0.69} | 442 {45.1} | 23.2 {2372} | 84 {8.6} | 68 {6.9} | 70 | 64 | 63 | 63 |

| 40 | 465 {47.4} | 23.2 {2372} | 80 {8.2} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 42 | 488 {49.8} | 23.2 {2372} | 76 {7.8} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 45 | 523 {53.4} | 23.2 {2372} | 71 {7.3} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 10 | 38 | 883 {90.1} | 46.5 {4744} | 169 {17.2} | 135 {13.8} | 102 | 81 | 77 | 78 | |||

| 40 | 930 {94.9} | 46.5 {4744} | 160 {16.3} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| 42 | 976 {99.6} | 46.5 {4744} | 152 {15.6} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| 45 | 1046 {106.7} | 46.5 {4744} | 142 {14.5} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| S6 | 6 | 48 | M6×25 | 13.6 {1.39} | 1116 {113.9} | 46.5 {4744} | 105 {10.7} | 87 {8.8} | 94 | 84 | 81 | 82 |

| 50 | 1162 {118.6} | 46.5 {4744} | 101 {10.3} | 87 {8.8} | 94 | 84 | 81 | 82 | ||||

| 55 | 1279 {130.5} | 46.5 {4744} | 91 {9.3} | 87 {8.8} | 94 | 84 | 81 | 82 | ||||

| 12 | 48 | 2232 {227.7} | 93.0 {9488} | 210 {21.4} | 173 {17.7} | 174 | 117 | 107 | 110 | |||

| 50 | 2325 {237.2} | 93.0 {9488} | 201 {20.5} | 173 {17.7} | 174 | 117 | 107 | 110 | ||||

| 55 | 2557 {260.9} | 93.0 {9488} | 183 {18.7} | 173 {17.7} | 174 | 117 | 107 | 110 | ||||

| S7 | 5 | 60 | M8×30 | 32.8 {3.35} | 2140 {218.4} | 71.3 {7280} | 115 {11.7} | 94 {9.6} | 124 | 109 | 105 | 107 |

| 65 | 2319 {236.6} | 71.3 {7280} | 106 {10.8} | 94 {9.6} | 124 | 109 | 105 | 107 | ||||

| 70 | 2497 {254.8} | 71.3 {7280} | 99 {10.1} | 94 {9.6} | 124 | 109 | 105 | 107 | ||||

| 10 | 60 | 4281 {436.8} | 142.7 {14560} | 230 {23.5} | 188 {19.2} | 270 | 159 | 143 | 149 | |||

| 65 | 4637 {473.2} | 142.7 {14560} | 212 {21.7} | 188 {19.2} | 270 | 159 | 143 | 149 | ||||

| 70 | 4994 {509.6} | 142.7 {14560} | 197 {20.1} | 188 {19.2} | 270 | 159 | 143 | 149 | ||||