技術資料 直動機器 ジップチェーンアクチュエータ ハイポイドモートル付 インバータ駆動のご注意点

インバータ駆動のご注意点

ZCA25M:モータ容量 60W-90W

- ・200V級はインバータ駆動できますが、低周波数および60Hz以上ではご使用できません。また、400V級はインバータ駆動出来ません。

ZCA35M・ZCA45M:モータ容量 0.2kW・0.4kW・0.75kW

- ・使用周波数範囲は最大120Hzであり、低Hz域(低周波数)はインバータの許容範囲内でご使用ください。尚、トップランナーモータ付0.75kWは標準モータで6Hz~60Hzの定トルク運転が可能です。

- ・高速域では、kW一定となるためトルクは回転数に反比例して低下します。また回転速度が上昇するため、モータ音、モータファン音、減速部音、振動などが増加します。

- ・低速域では、モータの運転効率と冷却効果が低下しますので温度上昇は大きくなります。トルクを下げてご使用ください。

出力トルク(%)はモータの60Hz時定格を100%とします。

(基底周波数を60Hzに設定)

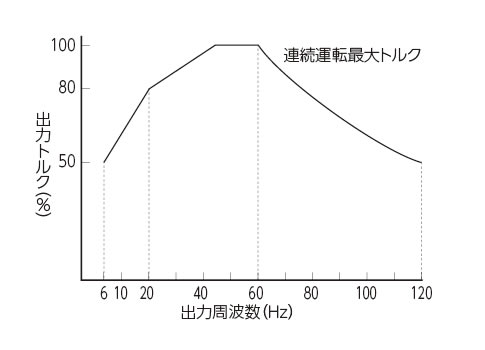

0.2kW・0.4kWモータの場合

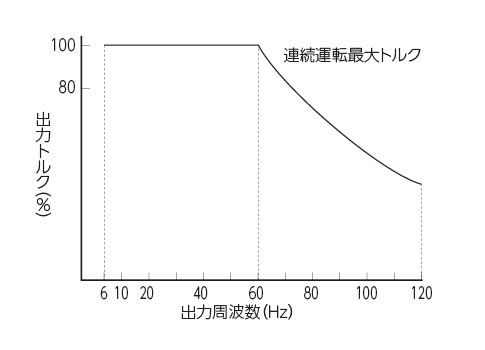

出力トルク(%)はモータの60Hz時定格を100%とします。

(基底周波数を60Hzに設定)

0.75kWモータの場合

ブレーキ制動の注意点

- ・ブレーキは所定の電源(周波数、電圧)を必要とするため、ブレーキ回路は別操作としてください。詳しくは「ブレーキ付モータ結線」をご参照ください。

- ・標準品では、ブレーキリード線をモータリード線とネジ止めの状態で出荷していますが、ネジをはずして別々に結線してください。

- ・制動時は60Hz(1800r/min)以下で行ってください。60Hz以上の高速域で制動を行いますと、機械的な損傷やライニングの異常摩耗・発熱などの不具合が発生しますので必ず60Hz以下で作動してください。

400V級モータをインバータ駆動する場合

- ・400V級モータは特形対応となります。400V級はインバータのスイッチングにより発生する高電圧のサージ(マイクロサージ)の影響で絶縁破壊が発生する場合があります。よって、これに対する対策(マイクロサージ対策)がモータに必要となりますが、当社の400V級モータには、ご指示がない場合でもマイクロサージ対策を施しています。ただし、そのレベルが1250Vを超える場合は、インバータ側へ抑制フィルタやリアクトルを設置してください。

その他の注意点

- ・温度上昇・騒音・振動は商用電源時に比べて大きくなります。

- ・モータ過熱保護のため、電子サーマルを汎用モータ特性に設定して使用するかインバータとモータの間にサーマルリレー等を設けてください。

- ・基底周波数50Hzで使用される場合、出力トルクは上表の×0.8としてください。 (0.2kW・0.4kWのみ)

- ・0.2kWと0.4kWではインバータモータ付の対応も可能です。