技術資料 機械式過負荷保護機器 取扱

ショックガード TGF 取扱

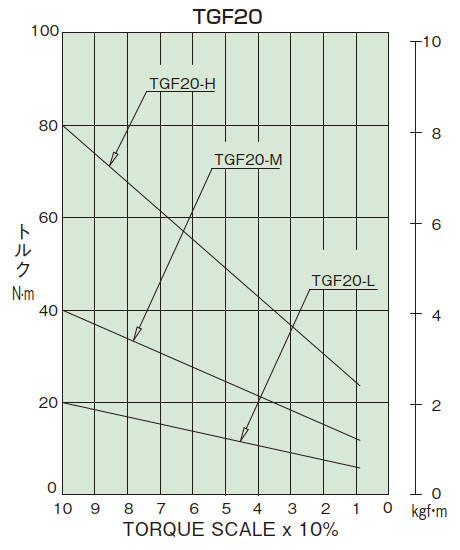

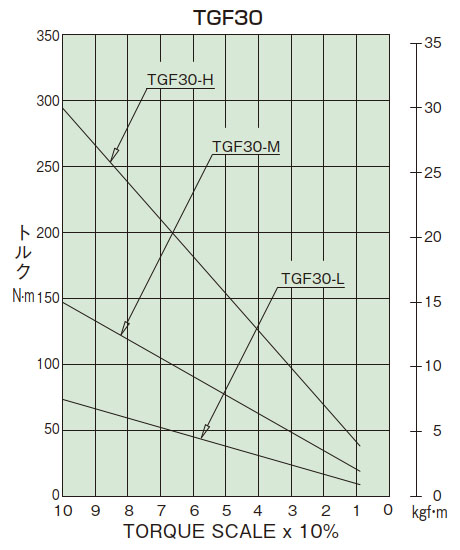

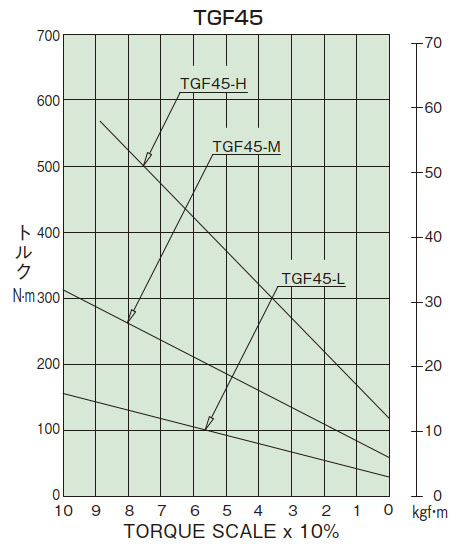

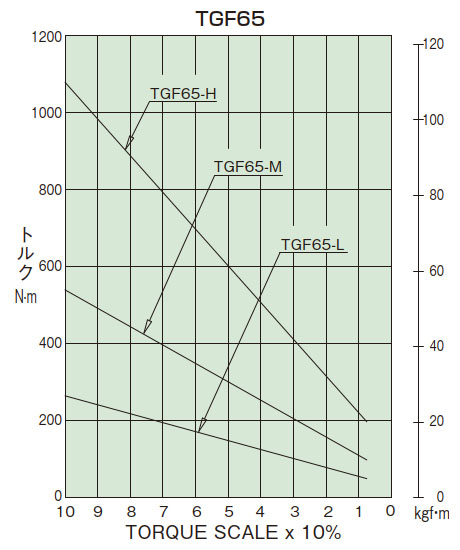

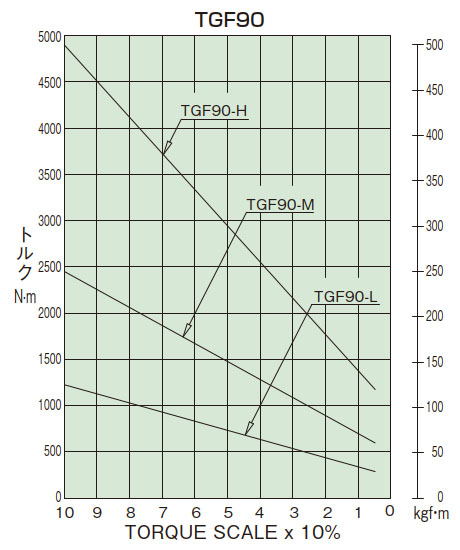

トルク調整

- 1. トルク相関図から必要トルクに対応するトルクスケールの値を読取り、調節ナット(6)をこの値まで締込んでください。調節ナット(6)を締込むには、ナットの外周の穴に引掛スパナか丸棒を差込んで回してください。注)TGF30、45サイズで必要トルクが高い場合(200N・m以上)は、専用の引掛スパナ(別売品)を使用してください。なお、TGF65、90サイズで必要トルクが高い場合は、ボルト(8)を一旦緩めて調節ナット(6)を必要とするトルクスケールまで六角穴付止ネジ(13)で調節ナット(6)を固定し、最後にボルトを完全に締込む事により容易にトルク調整ができます。

- 2. トルクが決定しましたらその値を銘板に追記しておくことにより、メンテナンスの時、分解しても容易に前の設定トルクに戻す事ができます。なお、ナットとハブの端面に合マークを刻印しておけばより正確に再現できます。製品のトルクは下の相関図と必ずしも一致しませんので目安として使用してください。

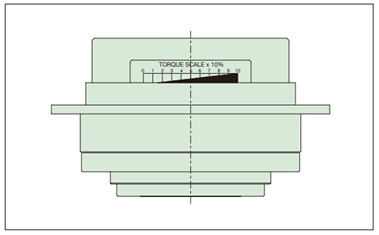

トルクスケール

トルク相関図